Contamination is a constant concern for food production facilities. Not only is it dangerous, but it is costly as well. Once there are contaminants within a facility, all production has to stop until the issue is resolved and the facility has permission to reopen, which can take months. This results in a significant loss of revenue, and it can mean a loss of respect from consumers, even if the contaminated product never affected consumers.

While facilities are required to have safety measures in place, there is more than one source of contamination to consider. Understanding what these pathogenic contaminants are and how to prevent them can help to ensure your food production facility runs smoothly without ever suffering from contamination.

What is a Pathogenic Contaminant?

A pathogenic contaminant refers to a disease-causing bacteria. There are many different kinds of pathogens, including Salmonella, Campylobacter, E. coli, Staphylococcus aureus, Listeria, Norovirus, and Toxoplasma, to name a few.

In many cases, these bacteria come from raw and uncooked meats, poultry, and eggs, though there are also other sources. Poor hygiene and sanitation protocols can aid in spreading these bacterias, increasing the risk of severe contamination concerns.

How Harmful Are They?

According to the FDA, there are an estimated 48 million cases of food-borne illness each year. Of these 48 million, an estimated 128,000 result in hospitalizations and 3,000 deaths.

The effects of these various pathogens can range from mild to severe; in some cases, they can even become fatal. Young children, the elderly, and those with chronic conditions and weakened immune systems are particularly at risk for infection from these pathogens.

5 Ways to Reduce Contamination

Taking the proper steps to reduce pathogenic contaminants in food is vital to maintaining a safe facility. Here are 5 ways to reduce the risk of contamination within your facility.

1. Set Up Entryway Sanitation Stations

Employees and equipment moving throughout the facility can introduce contamination without the proper precautions. Setting up sanitation stations at the facility's entrance and between production zones can significantly reduce the risk of contamination. These stations should include soap and water, hand sanitizers, and PPE for employees to use before entering the production area.

Using timed foamers to apply sanitizers to the wheels of equipment and even shoes can significantly cut down the risk of contamination. The use of sanitizing pellets on the floor is another step you can take to reduce the spread of harmful bacteria.

2. Understand Your Sanitizers

Sanitizers are critical in ensuring that harmful pathogens are eliminated, to prevent the risk of contamination. When considering the various sanitizers on the market, you want to choose one approved for your specific use case and follow the instructions carefully. This includes ensuring the product is appropriately mixed and diluted if necessary, that it stays on the surface for the recommended contact time and that the surface is thoroughly rinsed afterward.

To ensure the sanitizers are as effective as possible, you also want to remove any visible dirt and debris before application.

3. Invest in Employee Training

Employees are the backbone of the facility; without them, nothing would get done. Ensuring they receive the appropriate training is critical for the facility to run smoothly and maintain high sanitary standards. Instructing employees to stay home if they are sick is critical, particularly these days, with COVID-19 being a significant concern. Have CDC-approved signs posted, listing the symptoms, what to do if they suspect they exhibit symptoms, and how to prevent the spread of the virus.

It is also vital to provide detailed training on cleaning and sanitation protocols, so employees know the steps to follow and how to mix cleaning agents safely. Instruct employees to record who did the cleaning, what they used, and when it was done so you can always pinpoint any issues within the routine.

4. Use Germicidal Ultraviolet (UV) Light Systems

While cleaning agents and sanitizers should be your primary defense against bacteria and contamination, germicidal UV lights can provide additional sanitation. UV lights are scientifically proven to reduce bacteria and pathogens by up to 99%, without harsh chemicals. If you choose to install these lights, it is crucial to remember to only use them when the facility is empty, or no workers are present, as the light is harmful to the skin and eyes.

5. Install an Efficient, Sanitary Floor Drainage System

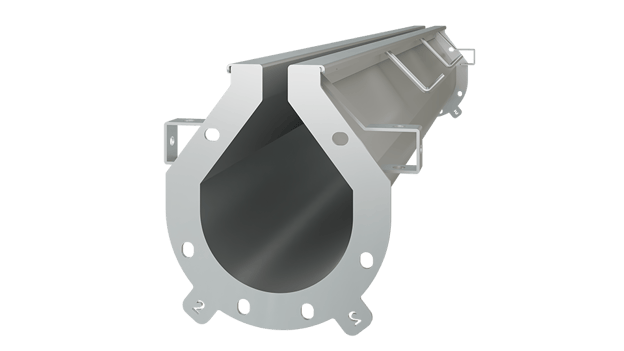

Drainage systems are vital to maintaining a sanitary facility by managing wastewater and keeping floors dry. FoodSafe Drains is a company dedicated to offering drainage solutions that help reduce pathogenic contaminants in food facilities.

The FoodSafe 10,000 Series Slot Drain and FoodSafe Trench Drain are two options designed to provide efficient, sanitary drainage. Area drains provide another option for drainage that can connect with the larger systems. These drainage systems feature an NSF-certified stainless steel design and offer clean-in-place capabilities for easy maintenance.

Reducing Contamination Risks with Proper Drainage

Pathogenic contaminants can ruin your facility's reputation and cost you thousands. Taking steps to reduce these pathogenic contaminants in food production facilities is essential to ensuring a safe, sanitary facility that meets government requirements.

These five ways to reduce the risk of contamination are possibly some of the most crucial. If you take anything from this list, make sure it is employee training, knowing how to use your sanitizers, and having a floor drain system.

To ensure these things are done right, it is best to find professionals in that given field. For floor drainage, contact FoodSafe Drains today, who can help you to determine the best system for your facility.