Due to the popularity of seafood, the need for fish processing plants has increased significantly. Fish processing plants deal with water more than other food processing plants, increasing the concern about bacteria and contamination within the facility. Ensuring sanitation in fish processing plant facilities is critical.

Follow these steps to help ensure maximum sanitation levels and prevent a serious crisis:

1. WATER SAFETY

Water is an essential component of fish processing plants, and water safety covers many areas. Water used for food and food-contact surfaces, producing ice, and separating potable and non-potable water sources is vital for facility sanitation. Any water should come from government-approved sources to ensure it is safe for food, food-safe sources, and human consumption. Monitoring is another essential part of water safety to ensure sanitation levels of potable water remain steady and any cross-connections don't lead to contamination.

2. CONDITION AND SANITATION OF FOOD CONTACT SURFACES

Anything that comes into contact with food products during production counts as a food contact surface. Keeping these surfaces clean is vital. Maintaining them minimizes the potential of them needing repairs or replacing. To ensure you aren't damaging the surface, you want to watch what products you use and the concentration level of the chemicals. The easiest way to avoid issues is to choose a material like stainless steel, which is resistant to bacteria and corrosion.

Inspect surfaces regularly, including gloves and outer clothing, to ensure it is in good condition, clean, and protecting the employees. With cleaners and sanitizers, test the chemical levels of the products to ensure they aren't too strong.

3. CONDITION AND MAINTENANCE OF EMPLOYEE HYGIENE AREAS

Employee hygiene is a critical part of any food processing plant. Hand washing, hand sanitizing, and toilet facilities are all required to help maintain the sanitation in fish processing facilities. You want to routinely monitor the condition of these facilities, ensuring they are clean and functioning properly. You want to repair toilets that are not working, keep all necessary supplies replenished, and ensure hand sanitizer meets the necessary concentration levels. Have all of these areas assessed by someone familiar with the requirements to ensure that nothing gets overlooked.

4. STORE, LABEL, AND USE TOXIC MATERIALS PROPERLY

Even though a fish processing plant deals with food, toxic chemicals are kept on the premises. Cleaners, sanitizers, insecticides, and lubricants for the equipment are just some of the chemicals that can be found. These chemicals are necessary for various reasons, but it is vital to take the proper precautions to ensure the fish and production area remain safe and free from harmful chemicals.

To prevent any dangerous situations, you need to take the time to organize, sort, store, and label all chemicals properly. Containers should be durable enough to handle the chemicals, especially if they are corrosive, and labels should be clear, providing the name, manufacturer information, and instructions for use. These chemicals should also remain away from food products and production equipment to prevent potential contamination or other damage.

5. PEST CONTROL

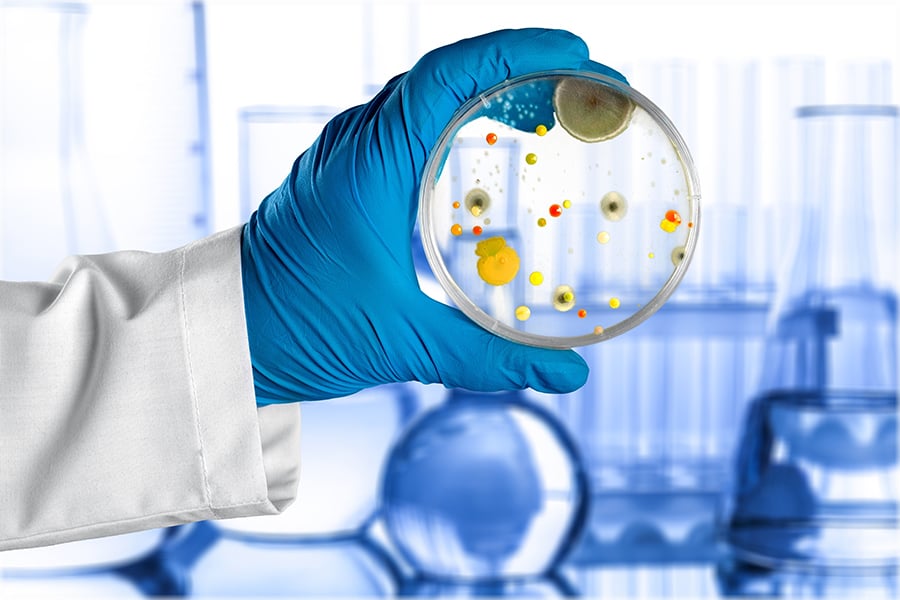

Pests refer to more than just rodents; it includes birds, insects, and other animals. Any pests inside a facility are incredibly problematic. They can create contamination, spreading bacteria like Salmonella, Staphylococcus, and Listeria, to name a few. Contamination can lead to a significant loss of revenue and cause damage to the company's reputation.

You need to ensure there are no entry points for pests and that deterrents are in place outside of the facility. Keeping the facility clean and free from food debris is also critical so that there is nothing to draw pests to the facility. Even with preventive measures in place, it is important to perform regular inspections to ensure the facility remains pest-free and take proper action if there are any concerns, to prevent a serious infestation.

6. INSTALL A SANITARY DRAINAGE SYSTEM

Floor drainage is a critical part of the sanitation in fish processing plant facilities. These systems help with water safety by keeping water from pooling on the ground, eliminating the risk of bacteria growing. By keeping floors clean, floor drains also help with pest control.

FoodSafe Drain's industrial strength 10,000 Series Slot Drain is the perfect addition to any facility. The drain features a seamless design with NSF-certified T304 or T316 stainless steel. A grate-free design means that inspectors can look at the drain without anything blocking their view–it also makes maintenance much easier, especially with the inclusion of a clean-in-place system.

KEEPING FISH PROCESSING FACILITIES CLEAN

Nobody wants to risk contamination in any food processing facilities. Fish-focused facilities require more care than others due to fish having special storage needs, which makes sanitation in fish processing plant facilities even more critical. Taking the proper steps to ensure a sanitized facility will create a safe environment to produce food products for the public. The better you maintain your facility, the better the products you produce will be, and there will be less risk for contamination.