In recent years, there has been an alarming increase in food-related product recalls due to contamination concerns. Every year, according to the CDC, an estimated 48 million people get sick, 128,000 are hospitalized, and 3,000 die from food-borne illnesses.

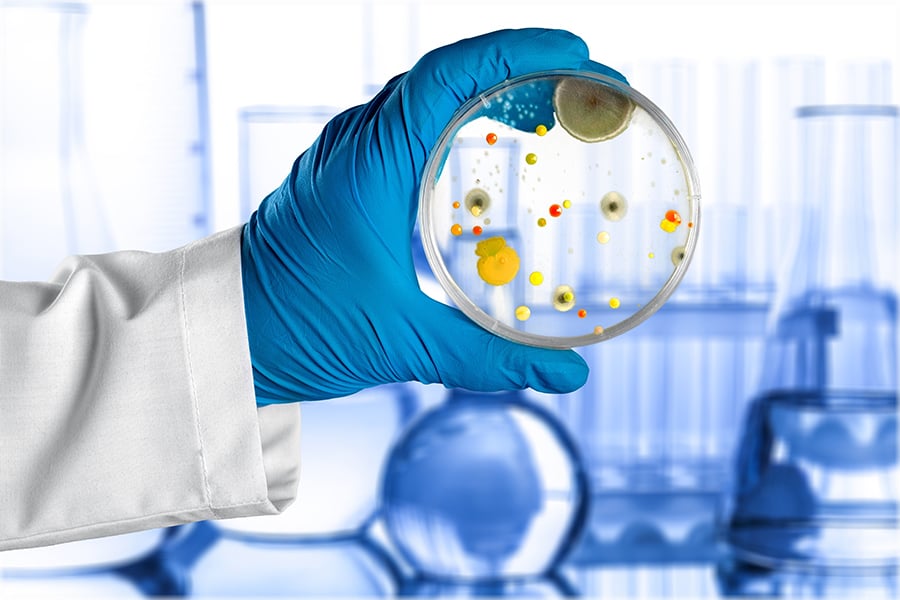

While these are alarmingly high numbers, they aren't surprising, considering how easy it is for dangerous pathogens like norovirus, E. coli, and salmonella to spread throughout a facility — especially when hygiene isn't at its best.

Fortunately, these high numbers have been a wake-up call for Americans, who are calling for improved food safety measures to remedy this serious problem.

A facility’s drainage is a key component to increasing food safety standards. Here’s how.

WHY FOOD SAFETY IS IMPORTANT

For food and beverage facilities, nothing is more important than food safety and sanitation. If a facility is poorly managed, it can lead to compromised food safety, which results in product contamination and the spread of dangerous food-related bacteria and viruses.

Because contamination isn't obvious at first, lax quality control may result in these products being released to the public. Consumption can then result in illnesses, some of them quite dangerous.

Along with harming the people who choose to purchase and often rely on that facility’s products, a brand’s reputation can become tarnished, resulting in losses due to both a decrease in consumer trust and recall costs.

With proper food safety measures in place, these problems are preventable. Simple things like the right setup, strict cleaning procedures, hand-washing, and safe handling of products can all significantly improve food safety. Another vital component is high-quality drainage.

FEDERAL STANDARDS

Food safety isn't a choice; it’s required by most governments. The FDA and USDA are charged with establishing the rules, regulations, and standards that food and beverage facilities are expected to abide by, which cover nearly everything, including what qualifies as adequate floor drainage.

According to the FDA and USDA, a floor drain should carry used water, sewage, and any other waste to the appropriate areas, preventing the spread of bacteria. Best practices also dictate that wastewater should flow in the opposite direction of your production processes.

CHOOSING THE RIGHT DRAINAGE SYSTEM

For food and beverage facilities, a trench drain is the traditional drain of choice. It features a wide drainage channel that is covered with heavy grates, which usually have larger holes to allow solid materials to be drained.

Although these systems are effective to an extent, their grate coverings can create major issues.Due to their weight, they’re fairly cumbersome to clean, which can result in fewer daily cleanings, leading to the growth of bacteria and other harmful pathogens. Trench drain grates can also be somewhat fragile, especially when it comes to forklift traffic, so replacements are often required.

There is, however, a more durable, easier to clean alternative in the form of a slot drain system. The FoodSafe Drains Slot Drain is a grateless trench drain system that has a smaller surface opening.

These linear systems are both pre-assembled (easy to install) and pre-sloped (preventing standing water) and are made using high-quality, food-grade stainless steel. As a result, they are bacteria-, corrosion-, temperature-, and even odor-resistant.

SLOT DRAIN MAINTENANCE

To clean these traditional trench drains, the grate has to be removed and cleaned separately. These grates are heavy, however, and can cause injuries if workers aren't careful. Bacteria can also harbor where the grate meets the trench, making it difficult to ensure total food safety.

A slot drain from FoodSafe Drains, on the other hand, has no grate, which makes cleaning much more manageable. It’s as simple as using a brush and paddle to scrub and move debris along the channel.

FoodSafe slot drains also feature clean-in-place considerations, as well as our Flush-Flo accessory, which can be automated to make cleaning the system even easier.

Because slot drains are made using non-porous, bacteria-resistant stainless steel, bacteria have nowhere to cling, making it easy to eliminate contamination.

INCREASE SAFETY AND EFFICIENCY

For food and beverage manufacturing facilities, food safety is paramount. Maintaining the highest level of sanitation standards ensures that products, workers, and customers all remain safe from contamination. While this is a multi-step process, one of the most crucial things you can do is ensure adequate floor drainage. Doing so will help keep floors dry and free from bacteria and allow water and sewage to flow to the appropriate areas.

QUESTIONS?

If you require effective, hygienic drainage for your facility, contact a FoodSafe Drains expert today. We’ll provide you with suggestions for your whole facility in order to help ensure proper sanitation in every area.