Bacteria and other foodborne pathogens are a serious concern for any food processing facility. Salmonella, E. coli, norovirus, and listeria are just a few of the possible bacteria that can result in contamination and serious illness if left unchecked.

It is the responsibility of all food and beverage processing employees to make sure that regular cleaning and other preventative measures are used to reduce contamination risks.

Here are a few prevention methods to consider, as prevention is always easier than elimination after the fact.

1. Invest in Germicidal Ultraviolet (UV) Lights

Thorough cleaning and sanitation are, without a doubt, the best ways to combat bacteria in food production, but germicidal UV lights can provide an additional level of sanitation. These lights are scientifically proven to kill a significant percentage (in some cases, up to 99%) of bacteria and pathogens. Without the need for harsh chemical, UV lights are an excellent tool to help you passively eliminate contamination.

UV lights can still cause harm to the skin and eyes, so it is critical to use them in empty facilities or in areas without workers. Unlike chemical cleaners, however, there is no wait time to enter the facility after using germicidal UV lights.

2. Keep the Floors Clean

This may seem like a no-brainer, but your facility floors are one of the primary areas where bacteria will linger and grow if left unchecked. From workers bringing in pathogens on their personal clothing to food and beverage materials falling from equipment, thoroughly cleaned and sanitized floors are imperative.

Keeping your clean floors as dry as possible is also a must. Many bacteria, including listeria, grow in water and other softer, wet material, so leaving messes untidied could result in bacterial spread and subsequent contamination.

Preventative measures for keeping bacteria off your floors in the first place is ensuring that no outside clothing or footwear is permitted on the production floor. Also, ensuring that the floors have the appropriate slope is important so that water and other materials can flow toward your floor drain system.

3. Color-code Cleaning Tools

One way to prevent cross-contamination and the spread of bacteria is to color-code cleaning tools, which will help speed up the cleaning process while preventing the use of any tools that shouldn’t be used in specific areas.

For example, one color can be used for surfaces that contact raw food products, like eggs and meat, which are notorious for carrying food-borne pathogens. Another can be for non-food surfaces. Facilities can have as many different colors as they need to ensure that there is no cross-contamination through cleaning tools.

4. Choose the Right Drainage System

Drainage systems not only help keep floors dry and clear of standing water and debris; they also help to transport harmful bacteria out of a food production facility. Well, the good ones do, anyway.

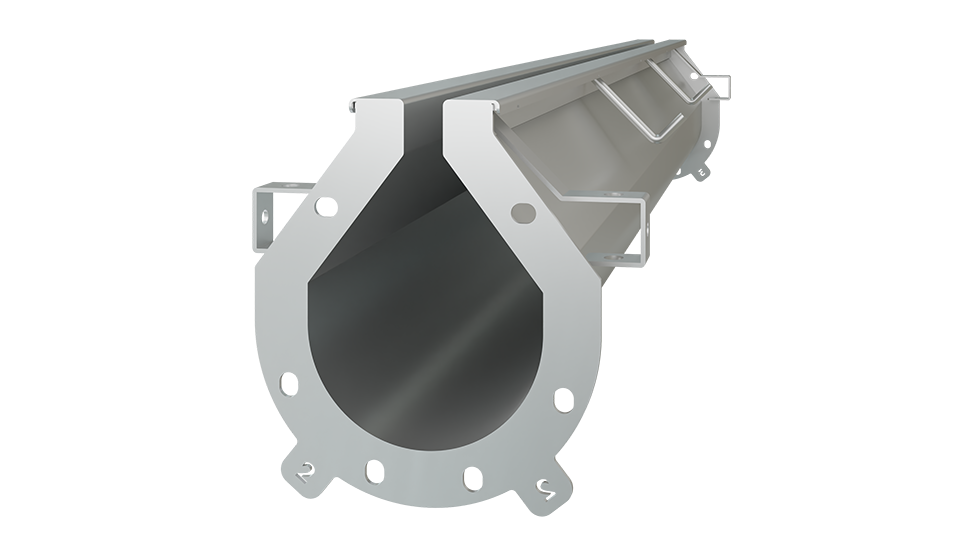

You don't want to choose just any drainage system, as not all floor drain systems are created equal. You'll want a system made of a nonporous, durable material, like stainless steel, that is easy to clean, safe, and durable.

Also ensure that your floor drain system has no hard corners, lips, or grates, which offer far too many places where bacteria can harbor and multiply. Other options to consider include clean-in-place considerations, automatic flushing systems, and ADA compliance.

5. Ensure Cooked Food Products Reach the Correct Temperature

Another way to reduce bacteria in food production is to ensure that food products are cooked to the correct temperature. Different foods require different temperatures to kill unwanted bacteria and make them safe for consumption.

Employee education is critical in this case, as controlling various cooking equipment must be a precise practice. Facility managers and maintenance personnel must also consistently ensure that the facility’s cooking infrastructure is in excellent working condition.

6. Keep Equipment Clean

All food processing equipment is extremely susceptible to contamination, especially those units that come into contact with raw materials. Any equipment with textured surfaces, cracks, or crevices is especially at risk of harboring harmful bacteria and other pathogens.

Preventative measures include thoroughly sanitizing every piece of equipment using all approved chemicals and cleaners at your disposal, as well as strict employee hygiene practices. Hand wash stations should be available through the facility, fully stocked at all times with the necessary sanitizers, soaps, and paper towels.

7. Clean the Freezing and Cooling Systems

Listeria, among other pathogens, can thrive in cooler environments, which means that refrigeration alone isn’t enough to stem its growth. Pathogens can attach themselves to evaporation plates, which help circulate cold air throughout the room, as well as other surfaces, leading to product contamination.

Standing water, dirt, and grime are also issues with these systems, as they automatically defrost to avoid ice build-up. Because of this, all components of your refrigeration and freezing units must be thoroughly sanitized on a regular basis.

Air filters should also be checked regularly and replaced as soon as it is necessary. This not only helps to eliminate pathogens, but helps maintain product freshness and quality as well.

8. Engage with Suppliers About Safety Measures

While suppliers, like farmers, take measures to decontaminate their goods before shipping, they may not be as thorough as is necessary, and their products may pick up bacteria and other pathogens while in transit.

Knowing this, facility managers must regularly communicate with all of their suppliers to discuss their safety and sanitation measures in order to coordinate efforts to eliminate contamination.

If safety protocols are not followed properly, then it is important to reevaluate your supplier relationships to ensure that everyone is on the same page with regard to food safety.

9. Clean the Air Handling System

Like heating and cooling systems, air handling systems have evaporation plates that help adjust the room temperature by controlling humidity. Therefore, bacteria, dirt, grime, and standing water are all issues for the evaporation plates. Condensation is another major concern with these systems because of water buildup.

To avoid this issue, maintenance professionals should be making every effort to ensure that everything is in excellent condition after cleaning the system. This can include the use of camera scopes to view hard-to-reach places, as well as various tests to ensure that no bacteria are present.

One System, Zero Problems

There is no denying that the biggest problem for bacteria in food production is standing water. Bacteria isn't the only issue with standing water; bugs, mold, and foul odors are also problems. You can do many things to deal with some of these issues, but the best way to deal with standing water is with the right drainage system.

Slot drains from FoodSafe Drains are designed with food production facilities in mind. The 10,000 Series system uses FDA-approved food-grade stainless steel, which is bacteria-resistant. The stainless steel channel is also resistant to things like extreme temperatures and corrosive materials, and it can take a substantial amount of weight, including forklift traffic.

What makes this system particularly unique is that it is pre-sloped and features a slim channel opening that doesn't require a grate cover, but can still handle high flow rates. As a result, it makes for a safer, more sanitary, and easier-to-maintain system, with clean-in-place capabilities.

Drainage questions?

To learn more about how highly effective sanitary drainage can drastically reduce bacteria in your facility, contact a FoodSafe Drains drainage expert today.