Food manufacturing is no easy job; operating food manufacturing plants is time-consuming and labor-intensive, and needs to be done correctly for many reasons.

Manufacturing plants are held to strict government rules, regulations, and requirements, which makes handling everything in your plant with care extremely crucial. Trying to cut corners or skip steps can increase the likelihood of accidents and contamination, and lead to serious legal issues. These issues are no laughing matter; you can effectively ruin your reputation and lose public trust with one wrong move.

That doesn't mean there aren't ways to increase efficiency within your plant and speed up the manufacturing process.

SPEEDING UP THE MANUFACTURING PROCESS

Speed in manufacturing has long been associated with a lack of quality. It can happen, but increasing speed and efficiency doesn't have to mean a loss in quality. Done correctly, it is easy to speed up the overall manufacturing process and make quality products.

Here are three things to implement in order to create speed and efficiency:

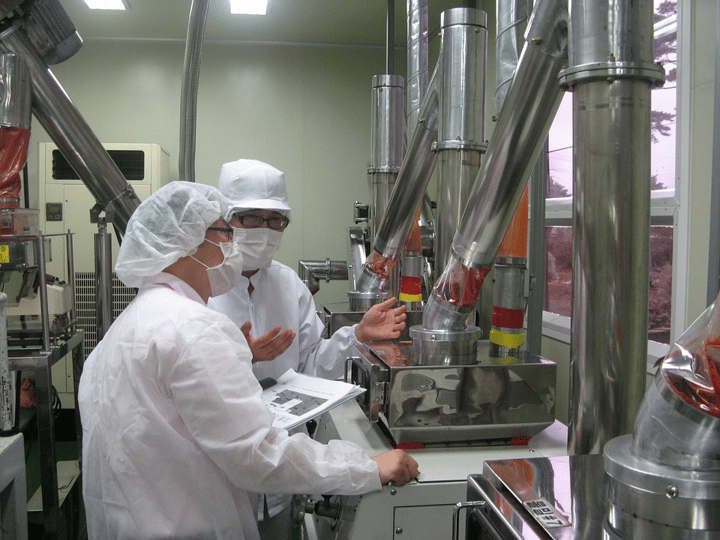

1. PUT TIME INTO EMPLOYEE TRAINING

Investing in the time to train your employees thoroughly is vital for every aspect of your facility. The more training that your employees have, the better they will understand the overall manufacturing process, and their assigned job. They will have more confidence and complete the task much faster than an untrained employee, without making simple mistakes.

Many facilities are turning to automation for specific tasks, but it is still important to train employees to do those jobs if the machines fail or have mechanical issues. Providing that training will ensure that production can continue while you wait for repairs or a replacement machine. Cross-training employees is also a good practice; so that when an employee is sick, you will have a trained employee to fill that spot for the time being.

2. INCORPORATE AUTOMATION

Having employees complete tasks by hand can have its benefits–it can also mean production takes longer. No matter how much training employees receive, some tasks are too time-consuming to do by hand, which means less efficiency in production. The best way to handle these more time-consuming tasks is by incorporating machine automation into your production line.

Automation allows for robotic machinery to handle different manufacturing steps without employee input. There are automated machines that can handle simple tasks like sorting, preparing, packaging, and others that handle more complex tasks like butchery. These are all tasks that can take time to complete by hand, especially to do it correctly. Automation can drastically cut down on time, making it possible for employees to focus more on other, non-automated tasks around the facility.

Automation has many benefits; it is an investment, and you need to buy high-quality machines that are built to last. Consider it carefully, and if you're willing to invest–it is worth considering when you are looking to increase production speed and efficiency. Automation helps the production line move faster, and it also eliminates the potential for human error for that given task.

3. INSTALL A RELIABLE DRAINAGE SYSTEM

.jpeg?width=720&name=IMG_0059%20(1).jpeg)

Maintaining a clean facility is critical to ensuring sanitation, but it can be time-consuming without the proper tools and setup. One essential piece of equipment to invest in to ensure proper sanitation levels is a drainage system. The 10,000 Series Slot Drain from FoodSafe Drains is a nicheless, grate-free trench drain system that has been designed with food and beverage facilities in mind.

The seamless design uses NSF-certified T304 and T316 stainless steel to create a bacteria and corrosion-resistant drain channel. It also features a heavy-duty load class rating, ensuring it can handle even the heaviest loads and equipment found in a food manufacturing plant. Flow rates vary from 11 GPM (per foot of drain) to 27 GPM (per foot of drain) depending on the slot opening, ranging from 1/2-inch to 1 1/4-inch wide. The slot opening ensures that large objects do not fall into the drain, and a catch basin and strainer basket can catch anything that does enter the system.

The system also has Clean-in-Place functionality for an easy, hands-off cleaning and sanitation process that allows employees to spend more time on other tasks, and therefore, be able to accomplish more during the day.

THE RIGHT WAY TO SPEED UP MANUFACTURING

Working in food manufacturing is no easy task; it is a time-consuming, exhausting job. As frustrating as it may be, you never want to try and take shortcuts with the process–whether through cutting corners or rushing the process. It can have severe consequences and can destroy your reputation. Instead of taking such risks, take the time to change things within your facility to implement these three methods of improving efficiency.

These simple changes can have a big impact on productivity within your facility. The more your employees can accomplish every day, the better your manufacturing plant will do overall, without sacrificing quality.