All poultry processing plants require a specific setup that is dictated by the federal government. There are guidelines for every aspect of a food processing plant, no matter how small it may seem. These guidelines are critical to creating a safe, sanitary facility and need to be followed carefully. This includes selecting the most efficient drainage system, which is an essential part of any poultry processing plant, in order to help to maintain a safe and sanitary facility.

Here is what you should know about choosing a drainage system for a poultry processing facility.

THE FLOORING MATTERS

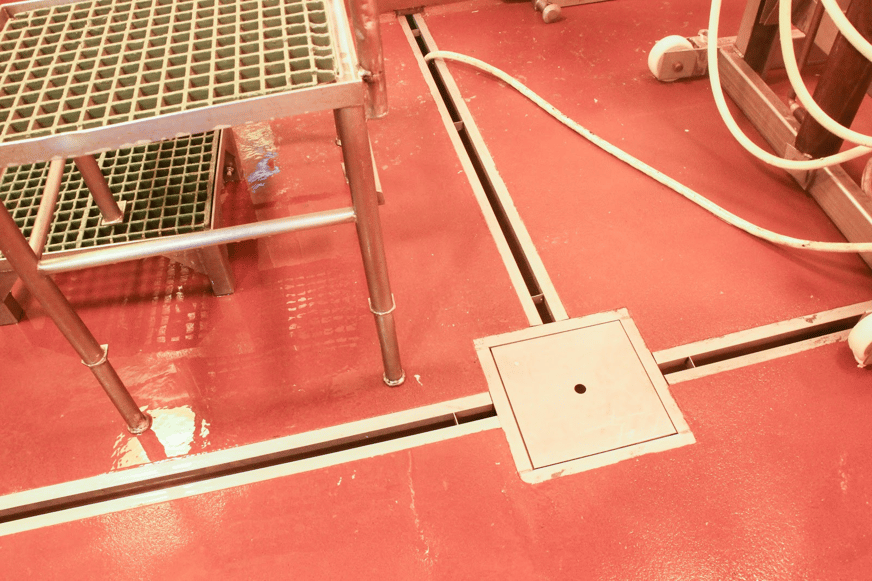

Before you can even start thinking about your drainage system, you need to consider the flooring. While it may seem an odd place to start, it is essential to remember that different types of floorings have different properties. For instance, you wouldn't choose the same flooring you have in your home because it would get damaged easily from the daily activity. The average flooring options also don't offer the antimicrobial properties that are important in a poultry processing facility.

A concrete base is usually the first choice of poultry plant designers, due to the ease of installation. The concrete is then covered in a thick, specialized coating to ensure it meets federal requirements for safe and sanitation. There are many different types of coatings–epoxy is one of the most common. There are other options like polyurethane and methyl methacrylate, to name some of the most common–and each has its own advantages and disadvantages. Do your research to choose the best floor coating, and then you can move onto selecting the drainage system.

CHOOSING A DRAINAGE SOLUTION

There are floor drains for a wide range of industries and applications, each designed to fulfill a specific set of needs. Poultry processing drainage needs to meet specific federal requirements for effectiveness, sanitation, and safety. Here are three reasons why Slot Drain's pre-assembled and pre-sloped trench drain is the ideal option:

1. GOODBYE GRATES

Traditional trench drain systems require grates–big, heavy drain covers that are difficult to clean, heavy, and break easily under too much weight. It makes for a less-than-ideal option in poultry processing plants, with lots of traffic and heavy equipment that can cause issues with grate covers.

The Slot Drain System eliminates that issue by not requiring grates, allowing for a much safer, stronger drainage system. The industrial strength Slot Drain systems are ADA compliant, and have a Load Class F rating, meaning they can handle up to 10,000 pounds of weight without breaking.

2. STAINLESS STEEL CONSTRUCTION

The construction of a drain system is important to consider. For poultry processing drainage, the USDA and FDA, have very strict requirements on what materials are allowed, which is stainless steel–a requirement that Slot Drain meets.

Stainless steel is the preferred material for many different reasons. For one, it is a very durable material that can handle extreme temperatures, both high and low, with ease. Aside from that, it is durable enough to handle the heavy weight of machinery and is corrosion-resistant, so harsh chemicals won't cause erosion.

Stainless steel is also a nonporous material, which makes it bacteria-resistant, so things like Salmonella and Listeria are less likely to cling to the walls of the drain channel.

3. CLEAN-UP IS A BREEZE

Maintenance is something that can pose a problem for most poultry processing facilities, so it makes sense to want a drainage system that is easy to maintain, with minimal labor. Because of its grateless, linear design, Slot Drain is incredibly easy to clean with just a brush and paddle. However, there is also the option of Clean-In-Place and Flush-Flo™ cleaning systems, which allow for efficient, more automated cleaning. This helps to give workers more time to focus on other areas of the facility, rather than drain maintenance.

DRAIN PLACEMENT MATTERS

Planning your poultry processing plant drainage system isn't done once you have your floor coating and drainage system chosen; you also need to think about effective drain placement. Consider the plant layout. Drains should go close to the work area(s), and near hoses and cleaning stations for ease-of-use. An effective drainage system is essential to reducing the risk of contamination which is critical in all food processing.

There is no denying that the Slot Drain System can easily meet all the federal requirements, at a reasonable price. The clean design, durability, and efficiency will provide a clean and safe environment for your poultry processing plant.

Contact FoodSafe Drains for more information on incorporating the Slot Drain System in your poultry processing plant.