Citrus has long been a popular fruit, with countless types available. The uses for citrus are endless, as are the ways you can enjoy it. To prepare citrus for consumers, it has to go through thorough processing. These processes are vital to ensuring the safety of the product. The multi-step process will remove pesticides and bugs and help ensure that the fruit is safe for human consumption.

HOW CITRUS GETS PROCESSED

Citrus fruit processing is a multi-step process that can vary depending on what products a facility is focused on creating.

STEP ONE: COLLECTION

The first part of citrus processing is fruit collection. Fruits are collected from the citrus grove, loaded into trucks, and taken to the processing facility. Once in the facility, they are stored in holding bins until the next step in the process.

STEP TWO: OIL EXTRACTION

The next step in citrus processing is oil extraction. The fruit goes through an extractor, to extract all the oils from the skin. The oil is then further processed, leaving pure citrus oil as the final product.

OR, JUICE EXTRACTION

Another option for citrus processing after collection is juice extraction. The process starts with juice finishing, which is essential for creating the right consistency in the final product.

Once the juice has been extracted, the pulp will be washed and sent through a pulp cell recovery process. After that, the final juice product is produced and is ready for distribution and sale.

7 PIECES OF ESSENTIAL CITRUS PROCESSING EQUIPMENT

There are many different pieces of equipment in a citrus processing facility. Some of the essential pieces necessary in a facility include:

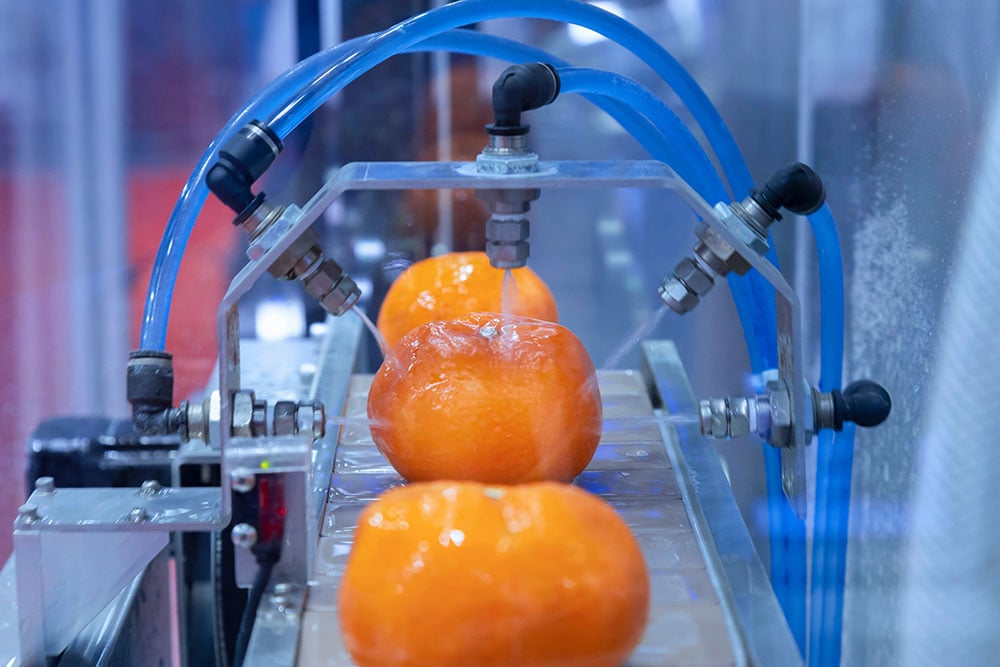

1. WASHING AND SORTING MACHINES

The washing and sorting machines are where the fruit first goes after entering the processing line. They are immersed in water and thoroughly washed before being rinsed with fresh water.

Afterward, the fruit moves through a sorting machine, to separate the best fruits from those that are rotten, unripe, or need to be discarded.

2. ESSENTIAL OIL EXTRACTOR

Essential oils are extracted from whole fruits by machines that scrape the peel off the fruit using rotating rollers.

3. JUICE EXTRACTOR

Juice extractors are another piece of citrus processing equipment. Machines squeeze out the pulp from the fruit to separate it from the peel and seeds. For these extractors, some companies offer two versions: one designed for fresh juice and another for citrus concentrate.

4. JUICE REFINERS

The product is refined to remove the pulp from the juice. These machines squeeze the liquid out of the pulp for a cleaner, pulp-free juice.

5. JUICE CONCENTRATOR

For citrus juice concentrate, the pulp passes through a different machine, which ensures low retention time and temperatures to help preserve the quality of the product.

6. JUICE THERMAL TREATMENT MACHINES

Whether juice is natural or concentrated, it can be pasteurized or sterilized. For this process, the product will go through thermal treatment machines.

Juice from the fruit can then be further processed into marmalade and other fruit bases for use in yogurts and other products. These types of processes require further specialized equipment, including machines for cooking the products and filling the containers.

7. A FOODSAFE FLOOR DRAIN

Not directly related to the citrus fruit processing line, a floor drain is essential to every food and beverage facility. Floor drains help keep wastewater from the floor's surface, to eliminate standing water that can result in bacteria growth and contamination.

FoodSafe Drains offers the Slot Drain System, a sleek, linear drainage system designed to blend seamlessly with the surrounding floor. Unlike traditional trench drains, the Slot Drain features a slim channel opening no more than 1-1/4" wide, which eliminates the need for a drain cover. It is constructed of high-quality, NSF-certified T304 and T316 stainless steel and features a heavy-duty load class, with flow rates up to 27 GPM.

FoodSafe Drains also offers a traditional trench drain system, which is better suited for facilities that produce juices, as they can handle large amounts of liquids. Like the Slot Drain, it features a high-quality stainless steel construction and heavy-duty load class. The drain cover is also tamper-proof, to help ensure that only authorized personnel can access the drain.

Both systems are also compatible with clean-in-place technology, making cleaning and sanitizing the system a quick, automated process.

EQUIPMENT MATTERS FOR CITRUS PROCESSING

Citrus products make up a large portion of the market, and the production facilities that handle these fruits require many pieces of equipment. We’ve briefly discussed some of the most essential pieces of citrus processing equipment you can find within a facility. Without this equipment, the quality of the products can suffer, and consumers may choose different brands. When choosing your equipment, take the time to choose the best.

For floor drainage, look no further than FoodSafe Drains. Between the FoodSafe Slot Drain and Trench Drain, there is an option fit for any facility.

Contact us today to learn more about our systems and see what is best for your citrus processing facility!