Food processing plants are held to very high standards and have clear rules and regulations that they must follow, which are dictated by the FDA and USDA.

While they oversee things on a grander scale, it is the role of facility managers to ensure that food processing plants meet all the necessary legal and safety requirements.

This includes making all necessary improvements and adjustments to ensure the facility is up to code. Not all changes may be visible, but finding every avenue toward improving your facility will produce measurable results.

IMPROVEMENT THROUGH DRAINAGE SYSTEMS

There are countless things facility managers can do to measurably improve their food processing plant, but the simplest way is to update the drainage system. Proper drainage is integral to the food and beverage processing industry, as it is one of the best ways to prevent bacterial contamination.

While all drainage systems ideally help to keep facilities clean, dry, and free of harmful bacteria, they are not all created equal. Efficiency, durability, and bacterial resistance are critical, which is why FoodSafe Drains Slot Drains are the ideal solution.

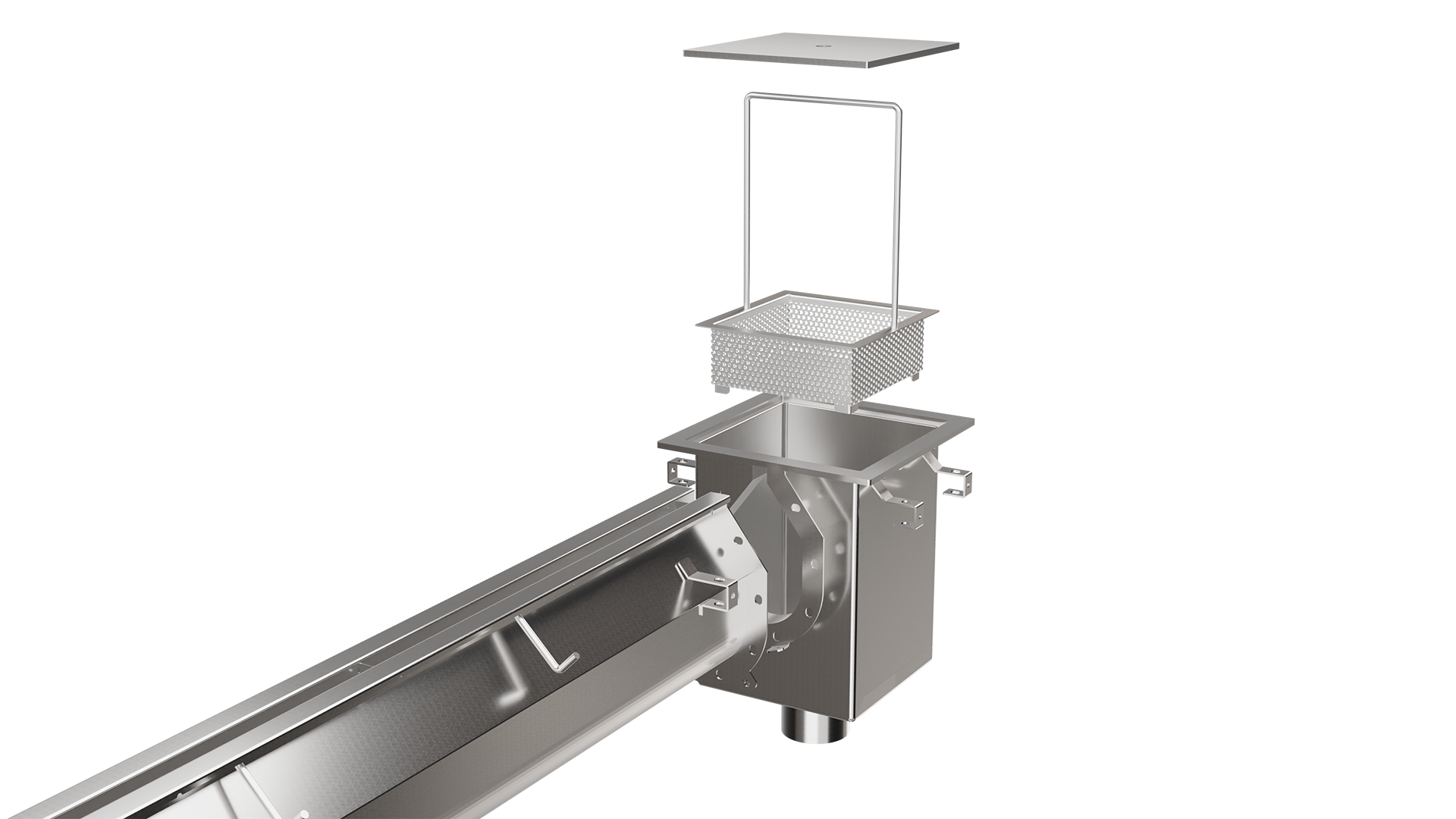

Slot Drains are high-quality, modern trench drain systems that are uniquely designed to function without a grate. A Slot Drain is a safer system that is more sanitary, durable, and easier to clean and maintain.

Here are the most important factors to consider when choosing a drainage system:

GRATED VS. GRATELESS DRAINAGE SYSTEMS

There are two common types of floor trench drain systems: the traditional kind, which requires grates to cover the wide drainage channel, and grateless systems, like the FoodSafe Drains Slot Drain.

It is crucial to keep in mind that grate covers add to the drain cleaning process and ultimately create more nooks and crannies where bacteria can cling and multiply. To properly clean a grated drain, you have to remove the grate, which has to be cleaned separately, and then clean out the wide drain channel.

This may not seem like a big deal, but industrial facility grates are big and heavy, and if you have hundreds of feet of drains in your facility, you’re looking at hours upon hours of cleaning. Grates can also get clogged with solid debris, and they can be quite heavy, which could lead to worker injury if not managed properly.

While grates can take a fair amount of wear and tear, they are not indestructible. Over time, they begin to wear down from exposure to various chemicals, changing temperatures, and heavy machinery. As a result, these grates require replacing every few years, creating additional expenses.

Naturally, grate-free systems, like the Slot Drain from FoodSafe Drains, do not have any of these issues. This saves a great deal of time and money on both cleaning and maintenance.

SAFETY CONCERNS

Safety is another factor for facility managers to consider when looking at drainage systems. With traditional trench systems, the two main safety concerns are the heavy grates and bacterial harbor points.

First, the grates are quite heavy, and having to remove and replace many of them in a work day can lead to injury, should they be mishandled. Second, trench drain grates have far too many sharp corners and perpendicular surfaces to ever be considered truly sanitary.

Instead, choose a grateless, lipless, cornerless Slot Drain system from FoodSafe Drains. The drain opening sits flush with the surrounding floor, offering no tripping hazards or hard edges where bacteria may be trapped.

Depending on the needs of your facility, FoodSafe Drains can also be ADA-compliant, with a slot opening as narrow as 0.5 inches. The inside of the drain channel has radiused edges, which means there are no hard corners where bacteria can cling and grow.

MAKING SANITATION A PRIORITY

The USDA and FDA are stringent in their rules for food processing plant sanitation, and floor drain systems must meet or exceed these expectations. Traditional grated systems can be more difficult to clean and maintain, which can affect their ability to be completely sanitary.

FoodSafe Drains’ systems, particularly the 10,000 Series Slot Drain, are made from FDA-approved, food-grade stainless steel, which is bacteria-resistant, as well as resistant to corrosion and extreme temperature.

Nonporous stainless steel, as well as a lack of hard corners, also ensures that food debris or other bacteria has nothing to cling to inside the channel. Another sanitary benefit of a Slot Drain is the pre-sloped design, which ensures that there is never any standing water in the drain.

Cleaning requires only a brush and paddle to help scrub the drain channel and move solid debris along toward the catch basin. Clean-in-place considerations are also available, including our Flush-Flo accessory, which allows you to connect a water line for manual or automatic flushing.

INDUSTRIAL-STRENGTH DURABILITY

In any commercial food and beverage production facility, you need a floor drain system that can withstand anything and everything you throw at it, including heavy foot traffic, cart and vehicle traffic, and even the weight of a forklift.

That’s why we’ve built Slot Drains with reinforced slot openings that can handle up to Load Class E. That’s strong enough for light vehicles to forklifts to semi-trailers.

FoodSafe Drains doesn't use stainless steel simply for its bacterial resistance. It is also a durable material that can also handle the temperature extremes found in a food and beverage processing plant.

EASY MAINTENANCE

To properly clean a traditional trench drain system, you have to remove the grates from each section and clean everything separately. It is a time-consuming, cumbersome task that could result in injury if workers aren't careful.

The FoodSafe Drains Slot Drain channel opening is much more narrow, but far easier clean. Using our brush and paddle tools, Slot Drain takes only minutes to clean per 10-foot section. There are also options for a flushing system called Flush-Flo, which can be used to manually or automatically flush the drain channel.

CHOOSING THE BEST DRAIN SYSTEM FOR MEASURABLE IMPROVEMENTS

All facility managers hope to make measurable improvements within their facilities, and an excellent place to start is with your floor drains. Drain systems play a significant role in maintaining a clean, sanitary facility, and the right system will make a noticeable difference very quickly.

Drainage questions?

Contact a FoodSafe Drains drainage expert today to learn more about how Slot Drain can drastically reduce the chances of contamination in your facility.