Food processing facilities are subject to strict rules and guidelines set forth by the FDA and USDA, which cover a wide range of topics, with most of the focus centered on the facility's setup and function.

The goal of these guidelines is to ensure that facilities are safe, sanitary and that they function properly. However, while regulations take many things into account, they generally omit many of the finer details that can ensure a facility’s operational success for years to come.

Even with all the guidelines clearly explained, nothing can replace the experience of facility builders and managers, who understand the fine details of facility design.

Meat processing facilities, for example, require a setup that is different from other food facilities, where all the fine details matter all the more. Even choosing the wrong drainage system can cause a major setback. Here are five common meat processing plant mistakes you want to avoid.

SKIPPING THE DESIGN TEAM

While facility builders and managers have a fair amount of experience creating functional facilities, they don't know everything. By working with a full design team, complete with experts in multiple disciplines, you can create a detailed meat processing facility plan.

This earliest of stages is critical in the operation success of any plant since innovative and food safety-conscious design details can prevent the need for premature repairs and refurbishments.

CHOOSING THE WRONG FLOORING

No matter what kind of facility you build, flooring should be a major consideration. It’s not just critical to the functionality of your facility; it’s a legality. Things like material, durability, and ergonomic ramifications should all be considered to ensure the safety of your meat processing plant, as well as the workers who spend their days on their feet.

Without the right flooring, the facility could be at risk of safety and hygiene issues, making it crucial to take the time to talk with the design team and floor specialist to determine which floor coatings are best. There are many options, but for meat processing facilities, one popular option is polyurethane coating, which is durable, offers thermal cycling resistance, and is easy to maintain.

CHOOSING THE WRONG DRAINAGE SYSTEM

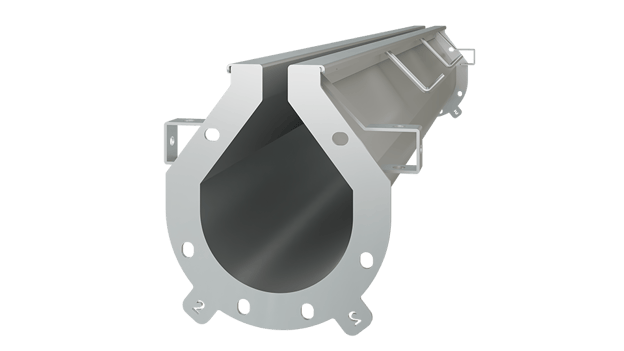

Drainage is as important as flooring when it comes to designing a meat processing facility, and equally important as any other piece of equipment on the production floor. Meat facilities use and generate large amounts of fluids, and any drain system you install needs to be able to handle all of it without overflow or allowing standing water.

While there are different options, none compare to FoodSafe Drains’ linear, grate-free slot drain system, which is FDA-approved and comes pre-sloped and pre-assembled, making it compatible with virtually all types of floor coatings.

The 10,000 Series model, like all our slot drain products, is made of food-grade stainless steel, which is resistant to bacteria, extreme temperatures, odors, and corrosion.

Slot drains from FoodSafe Drains are rated Load Class F, allowing them to withstand heavy forklift traffic. Thanks to the channel design, slot drains can handle large flow rates and are easy to clean, featuring clean-in-place considerations and automated cleaning options like our Flush-Flo.

MAKING THE FREEZERS TOO SMALL

Builders tend not to consider the amount of space required for freezers in meat plants. While “fresh, never frozen,” is an industry buzz-phrase, freezers are still a necessary aspect of the process in many cases. And if you don’t have enough space to store your product, it is left vulnerable to bacterial growth and potential contamination of your facility.

You will want to discuss this with your team to determine your facility's best options. It is important to keep in mind that these freezers will not hold just products, but shelves, carts, trays, and even chests as well.

Ensure that freezer space comes up early in design conversations.

NOT FUTURE-PROOFING YOUR VENTILATION

One last major mistake facility builders tend to make is not planning for the right amount of ventilation to see the facility into the future.

Ventilation is vital to a meat processing plant, since it keeps air circulating continually, which keeps condensation and odors to a minimum, preventing the growth of harmful bacteria, like salmonella and listeria. These can ruin products, make people very sick, and lead to serious legal consequences and a ruined reputation.

Work with specialists to ensure you select the right ventilation equipment that is effective enough to help mitigate these issues, even as you scale up production over time.

CREATE A SAFER MEAT PROCESSING PLANT

While the rules and guidelines set out by the FDA and USDA are important for all food facilities, they are especially poignant for meat processing. Working to meet these codes—and avoiding these common mistakes—can ensure the successful construction and operation of a meat processing facility.

QUESTIONS?

Contact FoodSafe Drains today to get in touch with one of our drain experts. We’ll provide you with drainage design suggestions for your whole facility to help promote productivity and reduce contamination risks.