In the food production industry, cleanliness is a primary concern. If the cleanliness of a facility becomes compromised, it can create health, safety, financial, and even legal issues. Preventing any of these issues from occurring requires a strong dedication to maintaining a clean and sanitary facility.

There are many steps to ensure the sanitation of your facility; one critical step is investing in high-quality floor drainage systems throughout the facility. There are many different systems on the market, but for food processing, trench drains with baskets from FoodSafe Drains are the safest and most effective option.

THE IMPORTANCE OF FOOD PROCESSING DRAINAGE

Food processing facilities produce large amounts of wastewater, which includes more than just water in many cases. When there is nowhere for wastewater to go, it becomes standing water, which can lead to many issues, including:

-

An unsafe environment for employees; workers can potentially slip on the floor and injure themselves

-

A breeding ground for harmful bacteria like Listeria, which can lead to contamination.

-

Standing water attracts bacteria-spread insects. Once an insect infestation begins, eliminating it can be difficult and costly.

-

Acidic waste that damages the floor can create unnecessary repair costs

Many of these issues are serious, and failure to handle them properly can lead to significant legal and financial repercussions. If contamination becomes an issue, there is an added concern about the company's reputation since consumers will lose trust in the products you create.

The easiest way to avoid these issues is by practising proper wastewater management and installing a sanitary drainage system. Floor drains eliminate standing water, to allow a facility's floors to dry more quickly to significantly minimize health and safety concerns.

HOW FOOD PROCESSING DRAINS WORK

Food processing drains are placed strategically throughout a facility to ensure optimal performance. Sloped floors are essential to a functional floor drain since water flows towards the drain with the help of gravity. The slope of the floors is slight, just enough to allow wastewater to move in the direction of the drain. Once in the system, wastewater moves through it, and is transported to the facility's chosen disposal system, passing through a catch basin that contains a strainer basket in order to filter out large objects.

LOOKING AT THE TRENCH DRAIN SYSTEM

Food processing drains are placed strategically throughout a facility to ensure optimal performance. Sloped floors are essential to a functional floor drain, since water flows towards the drain with the help of gravity. The slope of the floors is slight, just enough to allow wastewater to move in the direction of the drain. Once in the system, wastewater moves through it, and is transported to the facility's chosen disposal system, passing through a catch basin that contains a strainer basket in order to filter out large objects.

Trench drains have long been a popular drainage choice for a wide range of applications. They are commonly found in food processing facilities due to their high-capacity design.

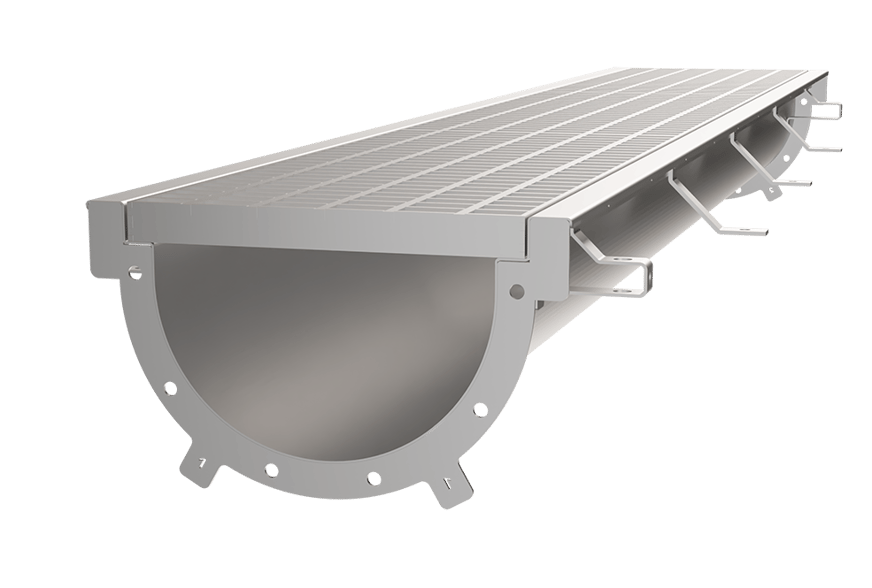

Trench drains have wide channels that prevent backflow and spills, ensuring that they never become backed up. A rounded-bottom design also helps to prevent bacteria build-up, making it more sanitary than other drainage options. Trench drain systems require a grate cover, which covers the drain channel and keeps solids of a specific size from entering the drain channel.

The food processing trench drains with baskets from FoodSafe Drains are a top-of-the-line option for food processing facilities. The systems feature a durable T304 or T316 stainless steel construction with an easily accessible channel with a rounded bottom that minimizes trapped bacteria to help ensure a sanitary system. The grate cover is also made from high-quality stainless steel and features a safe, trip-free design with Tamper-Proof locks for extra security, ensuring workers will never have accidents because of the grate coming loose unexpectedly.

WHAT IS A STRAINER BASKET?

A grate cover can stop some objects from falling into the drain channel, but it doesn't catch everything. A strainer basket can collect any significant solids you don't want to travel into the sewage tank like the smaller solids that get past the grate.

A strainer basket is one of the components that make up a trench drain system. It is found inside the system's catch basin and has 1/2-inch perforated holes that trap debris larger than the openings, preventing them from going through the drain channel. A strainer basket prevents clogs, and helps ensure the system is always working at full capacity, without any issues.

The strainer basket and catch basin are both made of durable stainless steel and are designed to last for the life of your drainage system. Catch basins include a reinforced cover made from stainless steel and rebar tie-ins, which can easily withstand heavy load capacities.

INVESTING IN THE RIGHT SYSTEM

The high amounts of wastewater seen in food processing facilities means that choosing the right drainage system for the job is essential. It isn't just a matter of the system handling large flow rates; you also need a system to assure that there are precautions in place to make sure the system does not become clogged and stop working.

Food processing trench drains with baskets from FoodSafe Drains are the perfect solution. This system can meet all your needs and more with its efficient, durable, and bacteria-resistant design. Contact FoodSafe Drains today to discover the right food processing trench drains for your needs.