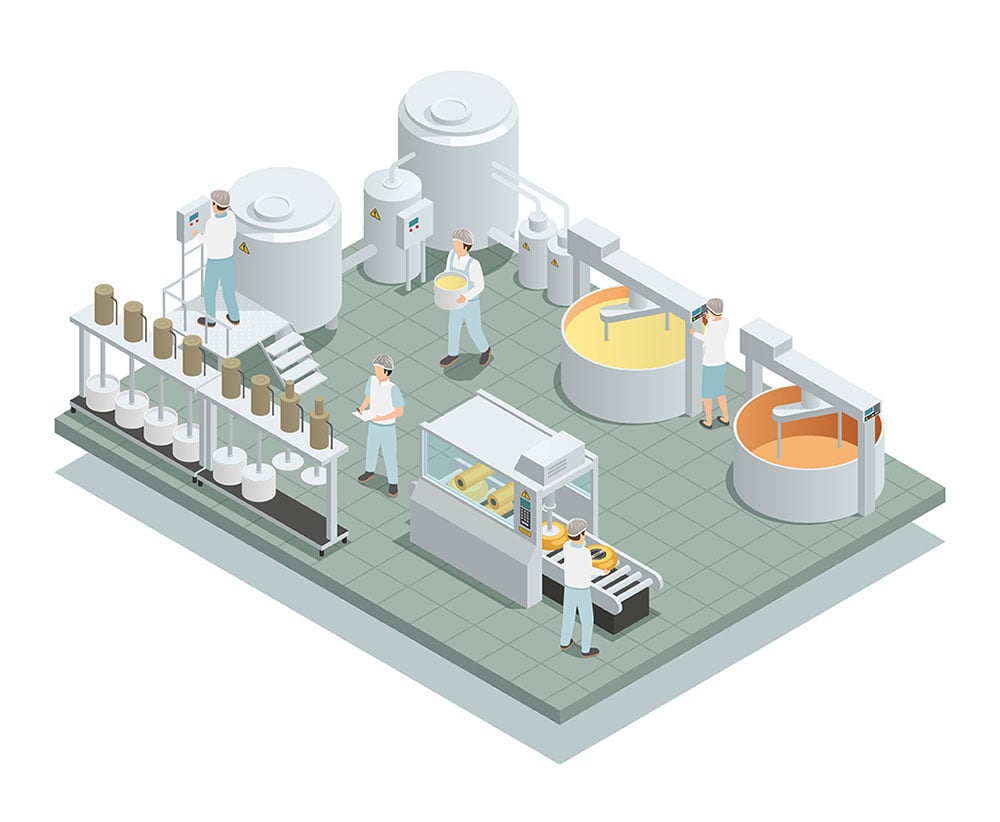

Food processing plants are responsible for processing most foods that are available to us on the market. To meet demands, processing plants need to run safely and efficiently, and for that to be possible, they need the right food processing plant design and layout.

Without the right layout, a plant can suffer from many issues, from lack of production to contamination. Here is what you should know about processing plant designs and layouts, including essential pieces to include and some examples to follow.

What is Plant Design? Why is the Design and Layout of a Food Processing Plant Important?

Plant design refers to the overall design of a manufacturing facility. It is a multi-step process that takes various factors into account, like the technical and economic factors, the various unit operations involved, and all currently existing and potential market conditions. Designing a processing facility also involves many other steps, including identifying the necessary equipment, the placement of that equipment, any waste treatment requirements, and much more.

The food processing plant design and layout is important for many reasons. The design and layout of a facility can significantly impact things like efficiency, flow, and employee safety. An improper layout can also affect how sanitary the facility is and can even lead to contamination.

Essential Parts of Food Processing Plant Design

Many essential factors go into a food processing plant design. Here are five elements you should not want to overlook in the design process.

1. Location

Deciding on a location is the first step in the design of food processing plant facilities. The ideal location will be relatively close to where the raw materials come from in order to minimize transportation costs and potential spoilage. Being reachable by emergency services is also vital in case any incidents occur where they may be needed.

2. Floors

Flooring is another essential element in the design of a food processing plant. The floors in a facility should be completely smooth, with no cracks or crevices, to help prevent bacteria from getting stuck and colonizing. The flooring material must also be strong enough to withstand the corrosive nature of chemicals used for regular cleaning and sanitation.

3. Drainage

Drainage is another aspect of plant design and layout that requires careful consideration. You need to select a food-safe system that has been designed to prevent and eliminate bacteria and contamination and still maintain the highest levels of sanitation possible.

The FoodSafe Trench Drain and Slot Drain are two such systems that feature T304 and T316 stainless steel and fully NSF/ANSI/3-A certified designs. Both systems feature a heavy-duty load class and automated, clean-in-place capabilities.

While similar in many ways, these two systems differ in size; the FoodSafe Trench Drain has a wide channel for larger flow rates and it requires a drain cover. The FoodSafe Slot Drain has a slimmer channel opening that eliminates any need for drain covers while still having flow rates up to 27 GPM.

4. Equipment

A food processing plant is nothing without the right equipment, and it is one of the most important parts of the design process. The equipment you choose should be from high-quality brands and specific to the products you manufacture or process. It will incur a larger initial expense, but you will have reliable equipment that won't break or become damaged after a few months. You want to look for materials like stainless steel for bacteria resistance and special features like clean-in-place to make cleaning and sanitizing more efficient.

5. Layout

The right layout is critical to food processing plant design as it will provide a safe and economical flow for the production line and employees. Examples of plant layouts include:

Product or Line Layout

With a product or line layout, the plant is either focused on a single overall product or a single product in a given area. The production stations follow the production line, with raw materials entering at one end, to make their way through the line with minimum work-in-progress and material handling.

There are many factors to consider before choosing a line layout, like the standardization of the product, ensuring a stable demand, and ensuring you have a reliable material supply.

Process or Functional Layout

This layout is for more process-focused systems and organizes the processing units by function into different departments based on the assumption that certain skills and facilities are shared in each department. That means instead of organizing equipment based on the production order, similar equipment and operations are together in the same group.

Cellular or Group Layout

A cellular layout is a functional layout where the facilities are clubbed together into different cells that can perform similar functions for a group of products. It is suitable for systems designed with group technology concepts, principles, and approaches. Cellular layouts offer the advantage of mass production with a high degree of flexibility.

Fixed Position

A fixed pattern layout is most suitable for producing single, large, high-cost components or products. With this layout, all of the labor, tools, and equipment come from different areas to the production site.

Creating the Perfect Layout and Design for a Food Processing Plant

The design and layout of a food processing plant can significantly impact how well the facility does. A well-planned facility will have all the right features and a layout that allows for efficiency in the production line that makes sense for the company. Take the time to consider the products you are producing so you can make the right choices the first time and not waste money, time, and resources. With the right layout, design, and other necessary elements, you will set yourself up for success with a sanitary, functional facility that runs smoothly and efficiently.

Contact the team at FoodSafe Drains today to learn more about the company and how their systems are essential to your food processing plant design and layout!