Food safety has long been a top priority for the U.S. government. Over the years, they have worked diligently to improve food safety in the country, by introducing rules, regulations, and more. Their newest approach to managing food safety and preventing the spread of bacteria and contamination is the Food Safety and Modernization Act (FSMA) of 2011.

What is FSMA?

The FSMA is considered the most comprehensive set of U.S. food safety law reforms in more than 70 years and is a complete overhaul of the food safety regulatory framework in response to the alarming number of yearly foodborne illnesses. It enables the FDA to better protect consumers by ensuring agencies and manufacturers focus on preventing foodborne illnesses rather than responding to outbreaks as they occur. The Act allows the FDA to impose recalls on contaminated products and requires businesses to submit new preventive protocols and safety plans. The FSMA has also expanded the agency's authority, to allow them to inspect businesses and supervise foreign transactions.

For food manufacturers to comply with FSMA regulations, they must submit and register with the FDA every two years. Businesses must create and implement both a Food Safety Plan and Food Defense Plan backed by science. They must also have preventative control strategies for hazards and other potential vulnerabilities.

What is an FSMA Food Safety Plan?

An FSMA food safety plan is an extension of the Hazard Analysis and Critical Control Points (HACCP) plans. FSMA plans have additional regulations businesses must meet and follow to be accepted. For businesses to meet FSMA complaints, food safety plan requirements must be met for all businesses regulated by the FDA–even if a HACCP plan is already in place.

Creating a Food Safety Plan

The primary goal of a food safety plan is to keep consumers safe and prevent illness or injury. It is crucial to consider the FSMA food safety plan requirements to ensure proper compliance. The requirements and regulations you are expected to follow can differ depending on your industry area and jurisdiction, if it is the FDA, USDA, or a dual jurisdiction.

Step 1: Create a HACCP/HARPC Team

To create a HACCP team, you must identify "Qualified Individuals'' according to FSMA guidelines. A qualified individual is someone who has been trained in the development and implementation of risk-based preventive controls (RBPCs). Whoever you choose for your HACCP team should also have the education, experience, and in-depth process knowledge about the product your business makes.

Step 2: Describe the Product, Intended Use, and Who It’s For

Your team needs to clearly understand the product you're manufacturing, who it is for, and its intended use. Recognizing that people will use the product, even if they are not part of the intended customer group, is equally important. Your team must plan for potential unintended users and develop preventive controls that will eliminate or minimize the risks to these groups.

Step 3: Create a Flow Diagram of Your Processes and Verify Its Accuracy

The next step in creating an FSMA compliance food safety plan is to create a flow diagram of all the manufacturing processes associated with your product. Once the diagram is created, you and your team should walk through the production area in the order of the manufacturing process to ensure that everything is accurate and nothing has been missed or overlooked.

The diagram should include the purchasing of ingredients and supplies. Identifying your supply chain is another requirement of FSMA food safety plans, as that is where the risk of contamination and bacteria begins. Understanding where your ingredients and the raw product come from is critical, especially if they come from overseas; your team must know or educate themselves about the countries your ingredients come from, as they must meet or exceed U.S. regulations.

Step 4: Conduct a Hazard Analysis

For your flow diagram, your team will then develop, assess, and identify all associated hazards, which include:

- Microbiological: Microbiological hazards can vary depending on the product. They can include bacteria, viruses, prions, and parasites.

- Chemical: Chemical hazards typically refer to food allergens like milk, soy, egg, and peanuts. You should also be considering the potential for radiological materials.

- Physical: Physical hazards include hard, foreign objects like plastic, metals, or stones that can result in injury or choking.

Step 5: Determine CCPs and Establish Critical Limits

The next step in creating a food safety plan is determining if any process steps are a CCP (Critical Control Point) or Risk-Based Preventive Control (RBPC). This involves considering how you control the step to reduce potential risks to a more acceptable level, and where in the process this happens. Aside from identifying any CCPs and RBPCs, you also need an established limit, which you must meet or not exceed. These limits are established through a combination of scientific research, regulatory requirements, or historical plant data.

Preventative measures can include many things. One often overlooked FSMA food safety plan example for CCPs and RBPCs is installing appropriate floor drainage measures.

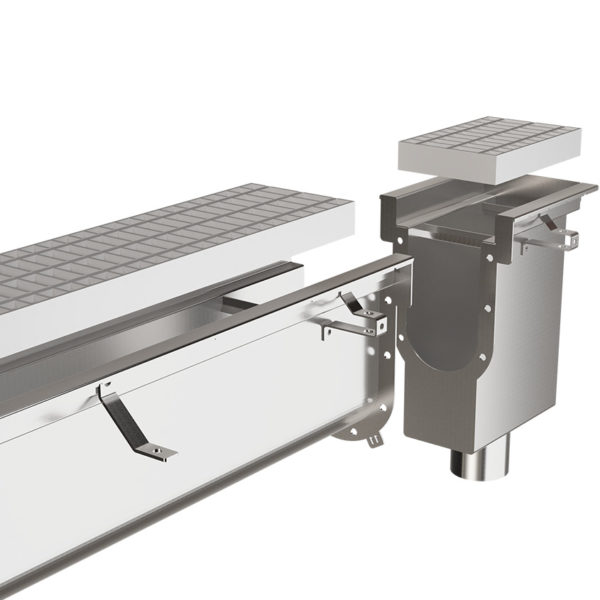

Systems like the FoodSafe Trench Drain and Slot Drain assist in creating a sanitary facility and help to significantly minimize microbiological risks FoodSafe also offers a variety of other commercial drainage products designed with food safety in mind that meet FDA and USDA standards.

Step 6: Establish Monitoring and Corrective Actions

Next, you will need to determine where the CCPs or RBPCs will get monitored in the production process, and who will do the monitoring. Whoever is in charge of this must receive thorough, documented training to ensure they understand what they are monitoring, how they will monitor it, and why it is being monitored. It is also vital they understand the importance of proper and accurate documentation. You must provide them with the proper monitoring tools and determine an individual qualified to review and validate the collected data.

If you find your process exceeds the established limits, your team must assess the situation and determine the best plan of action to correct the issue and ensure compliance.

Step 7: Establish Verification and Record-Keeping Procedures

Verification is an essential part of a food safety plan, which refers to ensuring that you are doing the things you have identified will ensure a safe product, which is done using the collected data.

The final part of a food safety plan is determining how long you keep records and how they are controlled. As a general rule, documents should be kept on file for a year past the shelf life of a product, when possible.

Ensuring Consumer Safety with a Food Safety Plan

With the FSMA, the FDA has changed how they approach food safety. Instead of waiting for foodborne illnesses to happen, they are working to prevent them from ever happening in the first place. A large factor in these preventative measures is creating a reliable, in-depth FSMA food safety plan that addresses all potential hazards thoroughly.

Take the time to create a plan and ensure it meets all FSMA food safety plan requirements so that you will remain compliant with the FDA.

FoodSafe Drains can help you with their FDA-approved drainage systems that ensure clean, sanitary facilities. Contact the team at FoodSafe Drains to learn more about our NSF-certified products and see what would work best for your facility!