Juice is a popular beverage, with juice sales making up a significant portion of the beverage industry. High-quality vegetable and fruit juices aren't just flavorful; they are full of essential vitamins and nutrients that are good for the human body.

Fruit juices are the most popular, and creating them on a commercial scale requires great attention to detail to ensure the product is produced safely and sanitarily. High levels of juice production require more than the simple home juicer.

Here is a brief commercial fruit juice processing equipment 101 to break down what a fruit juice plant needs to operate.

ABOUT COMMERCIAL FRUIT JUICING

The production process for fruit juices is fairly standard, regardless of the type of juice you are making. The process starts with the pretreatment of raw fruit material and then moves to extraction, clarification, and filtration. From there, the production process continues with homogenization, deoxidation, concentration, and ingredient adjustments.

Finally, the product reaches the final stages of production: packaging and sterilization, so it can be shipped out to stores for consumers to purchase. Each of these steps requires specific pieces of processing equipment.

7 ESSENTIAL PIECES OF EQUIPMENT

These are 7 vital pieces of equipment for fruit juice processing:

1. THE WASH LINE

The first step in the juice production process is sending raw fruit ingredients down the wash line. The wash line is a vital piece of equipment that every facility needs; this is where the fruit gets cleaned, to remove all traces of dirt and pesticides and prepare them for processing. Once products pass through the wash line, they continue along to a grinder, the next step in the process.

2. GRINDING EQUIPMENT

The next key piece of equipment is the grinder. The grinder prepares the raw ingredients for the extraction process and comes in various sizes and capacities. What a company chooses depends on its desired processing rate, how much incoming product they have, and the desired particle size of the final ground product. Once the raw ingredients pass through the grinder, a pump will transfer it to the extraction equipment.

3. PUMPS

Pumps come in various designs and sizes, and finding the right one is essential to keep the production line operational. The most common pumps used in fruit juice production are: progressive cavity and lobe pumps. Progressive cavity pumps can better deal with products that contain larger particles or have a high viscosity. Lobe pumps are better for juices with high acidity and low abrasiveness.

Keep in mind that pumps should only transfer products to the next production stage, not perform further size reduction.

4. EXTRACTORS

The kind of juice extractor you choose for small scale fruit juice processing equipment depends on what type of fruits you are processing and your end objective. Some processing plants may only have one extractor, and others may use several types to process their products entirely.

There are many types of extractors available: belt presses, screw presses, rack and cloth presses, and centrifuges. Like pumps, you want to use the right reduction size for your extractor for optimal performance.

5. MIXING TANKS

Another critical detail for commercial fruit juice processing is mixing tanks. Mixing tanks are a vital part of the production process and involve multiple ingredients. The mixing tanks are for the mixing of concentrate, fruit pulp, preservatives, water, flavor, color, and more. Tanks come in various sizes and materials and vary in price.

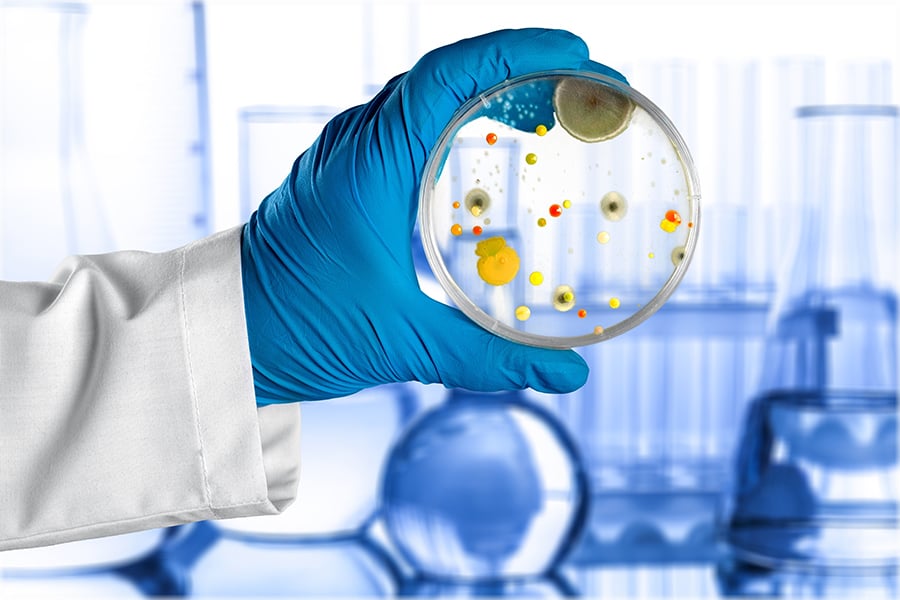

6. PASTEURIZERS

Pasteurizing is vital in the production process, making this an essential piece of processing equipment. Pasteurizers kill potentially harmful bacteria, and ensure the juice is safe for consumption. All facilities should invest in high-quality pasteurization equipment made of quality materials that are easy to clean and won't hold onto bacteria.

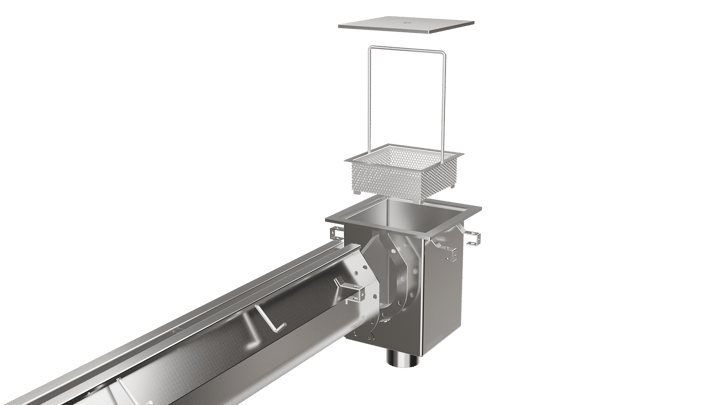

7. A SLOT DRAIN SYSTEM

An overlooked part of commercial processing equipment is drainage systems. Having a high-quality, reliable drainage system is vital to any processing plant. The 10,000 Series Slot Drain from FoodSafe Drains is one of the most hygienic systems on the market, and it features a seamless, no-niche design. It comes ready for installation and is easy to retrofit into existing facilities looking to upgrade their system.

Unlike more traditional systems, Slot Drain does not require a cover as its slot opening, which is easier to clean, and comes with clean-in-place capabilities. The system is NSF-certified and constructed using either T304 or T316 stainless steel, to ensure it is safe for food and beverage facilities.

The 10,000 Series also features a heavy-duty load class rating. This ensures that it can handle the heavy traffic and machinery in a fruit juice processing facility without damage. The high flow rate capabilities further ensure the system will never fail.

FRUIT JUICE PROCESSING ESSENTIALS

With the popularity of fruit juices, new facilities are continuously emerging. Whether you are looking to start a large commercial operation or do small-scale fruit juice processing, the equipment you use matters. Without the right equipment, a facility cannot function properly, and investing in the wrong equipment can result in significant financial losses.

Take the time to plan out your facility from the ground up. Contact the experts at FoodSafe drains today to discover the best options for draining fruit juice processing plants.