The building of food processing plants is a strictly regulated process in the U.S. Agencies like the FDA and USDA play a significant role in creating the rules for their safe operation and maintenance, while also outlining guidelines and tips for the building of new facilities.

Here are the most critical considerations for a new food or beverage processing facility.

CONSIDER THE LOCATION

Aside from municipal zoning bylaws and other regulatory factors affecting a new food facility’s location, there are other considerations to make.

Ideally, a food plant should be near the raw materials it uses, whether it is a farm or another source. This can significantly cut down on material transportation and spoilage, saving facility managers a great deal in operational costs.

Emergency access is also critical in case of a medical or facility-related emergency, such as a fire or chemical leak.

SET UP A WORKER SANITATION AREA

To prevent outside bacteria from entering a food facility’s production floor, a worker sanitation area should be set up at the worker entrance and should include handwashing stations and an area to change into a sanitary uniform that includes a mask, hairnet, gloves, and shoe coverings.

Depending on the type of facility, other sanitary entry procedures may be required, like a Danish entry system.

Handwashing stations should also be present throughout the facility, along with access to fresh gloves, hairnets, and other sanitation essentials as needed.

CHOOSE THE RIGHT FLOORING MATERIALS

In a food and beverage processing facility, anything but a concrete floor with a suitable coating is out of the question. Sealed concrete floors offer a smooth surface without cracking or lines, which allows equipment and workers to move over it safely without damaging it.

Floor coatings like epoxies and polyurethane are the most popular for food facilities, since they’re durable, easy to install, and prevent bacterial build-up by protecting the concrete underneath and being extremely easy to clean.

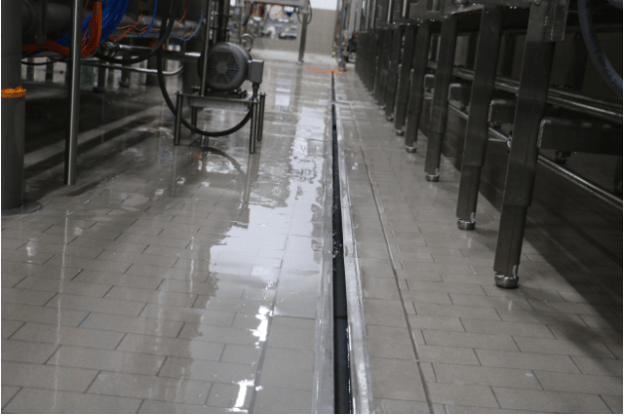

INSTALL SANITARY FLOOR DRAINS

Sanitary floor drains are critical for food processing plants, as they help keep floors dry while preventing bacterial build-up, which can cause odors and spread contamination through the facility.

Slot Drain's 10,000 Series floor drain system features a unique, grate-free design that is both effective and durable. It is constructed of high-quality, food-grade stainless steel that meets both FDA and USDA guidelines and is corrosion-, bacteria-, and odor-resistant. The system also offers easy maintenance, either with a brush and paddle or automated options like Flush-Flo and other clean-in-place considerations.

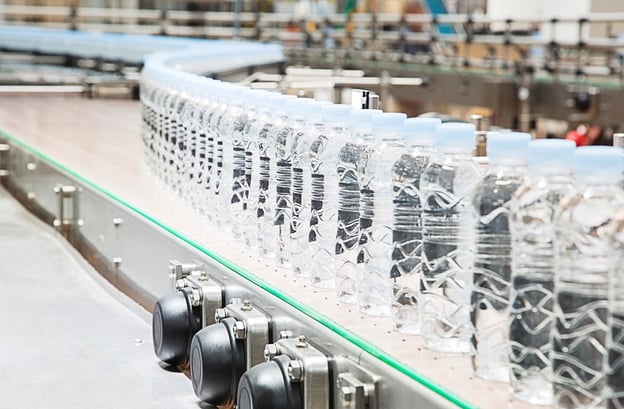

INVEST IN THE RIGHT EQUIPMENT

The public trusts food production facilities to function in a safe, sanitary manner, without the worry of contamination or machinery failure. Part of that means ensuring that a facility uses only high-quality equipment and maintains it to high standards.

Where possible, bacteria-resistant stainless steel should be used in order to mitigate any contamination risk caused by raw materials. Equipment should also be easy to clean, with full wash-down capabilities where possible.

CREATE DESIGNATED CLEANING STATIONS

Designated cleaning stations should be strategically placed throughout a facility and include water hoses, mops, and other cleaning tools that could help clean up spills or other accidents.

These stations will allow workers to clean as they go throughout the day, preventing contamination on an ongoing basis and minimizing cleaning requirements at the end of a production day.

DECIDE ON A SMART LAYOUT

You can have every other aspect of your food plant design figured out, but it won't matter without the right layout. Food facilities should flow in the production order, with raw materials at the start and finished product at the end.

Similarly, employee pathways should flow in one direction. This will prevent contamination across the production line, while enhancing safety and accountability.

BUILDING A SUCCESSFUL FOOD PLANT

The seven considerations in this article are some of the most critical aspects of building a food processing plant. Keeping these in mind, you can create a safe, sanitary, and successful food processing plant.

Questions?

FoodSafe Drains can help optimize your food processing plant’s efficiency with a line of sanitary drainage solutions. Check out our whole-facility drainage design guide to learn more about the right drainage for your operation, and contact us with any questions you may have.