Similar to prepared food and meat processing plants, a dairy processing plant must meet the strict requirements set forth by the FDA and USDA (or other governing bodies if you’re outside of the USA).

In large part, these requirements are concerned with safety and sanitation, since the risk of contamination in dairy products is so high. In order to ensure the highest-quality, safest products for consumers, the following four considerations are critical to dairy plant setup.

1. Layout is Crucial to Your Operation

Dairy plant layout should, first and foremost, follow the basic principles of food production, which means that production should flow from raw milk to finished dairy products, with no backtracking.

Where possible, layout should also eliminate the need for workers from various parts of the process to cross paths. This will help to minimize contamination risk on either end of the production line.

2. Buy the Best Equipment You Can Afford

Required dairy plant equipment includes all kinds of machines, from antibiotic testing equipment to everything involved in the pasteurization process to bottling and packing machinery. The majority of dairy processing plant equipment is incredibly specialized and not something you want to buy cheaply.

A processing plant requires high-quality, stainless steel equipment, which helps prevent bacterial growth. This will ensure that the equipment is safe, sanitary, easy to clean, and durable. By investing in high-quality equipment from the beginning, you can ensure dependable performance, which will, in turn, lead to the highest-quality products possible.

3. Hire Reliable Employees and Train Them Well

Great employees are the backbone of every successful dairy processing operation, as they handle things like transporting milk, testing it, and managing the plant's equipment throughout all processes.

All employees require in-depth training to ensure that they understand the safety requirements for the various tasks they need to complete, including all cleaning procedures. They also require training on the proper cleaning and sanitization techniques to prevent the spread of bacteria and contamination.

Other training includes personal hygiene requirements, such as hand washing, uniform requirements, handling equipment malfunctions, and handling potential safety issues.

This training should be periodically updated and retaught to ensure that all employees are always up-to-date on rules, tasks, and expectations.

4. Use the Right Floor Drainage System

While not specific to dairy processing plants, a floor drainage system is a vital piece of equipment that helps to maintain a safe, dry, and sanitary facility. Since 70% of positive listeria screens are found in a facility’s floor drains, choosing the right system for your application is absolutely crucial.

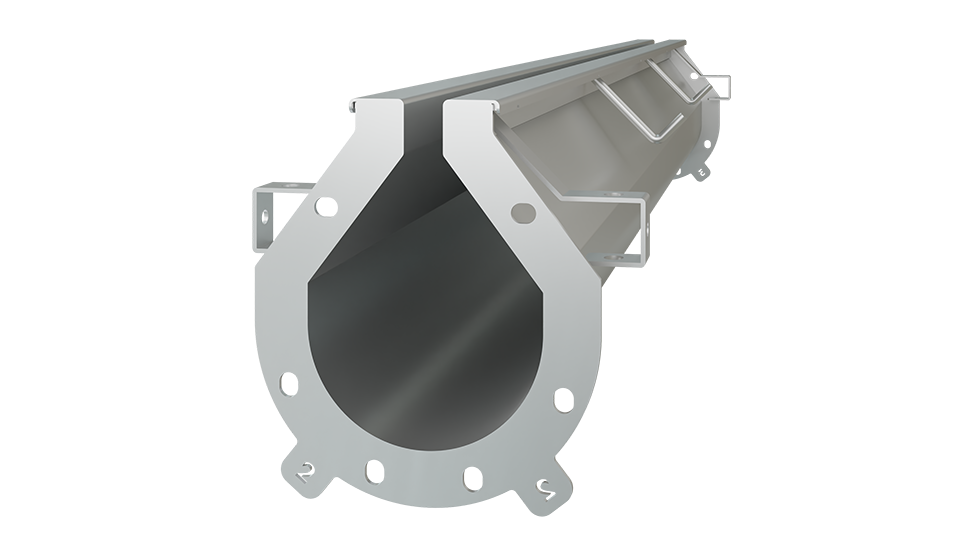

The best system for any food processing facility is the Slot Drain from FoodSafe Drains. These pre-assembled, pre-sloped systems are made from bacteria-resistant stainless steel, which is also resistant to extreme temperatures and corrosion.

These highly durable drains are easy to maintain and can be quickly cleaned using our brush and paddle tools. Accessories are also available to allow for a water line connection, which can be used to flush the drain channel, or clean-in-place options are available.

Ensure Success with the Right Setup

While there are a great many variables in play when it comes to dairy plant setup, these are some of the most critical. Ensuring operational success means doing all the right things from the start and continuing to strive for quality in all that you do.

Questions?

If you have any questions about how FoodSafe Drains can benefit your dairy processing plant, contact one of our experts today, and we’ll be happy to assist with your project.