Seafood is one of the most popular types of food, with an estimated 4.5 billion pounds consumed annually in the U.S. alone. Fish like salmon, tilapia, and cod are just a few popular types of fish that people enjoy.

Like all food products, these types of fish must go through a processing plant to ensure they are safe for consumption. Processing plants clean and prepare the fish for sale, sometimes even smoking them or using other methods.

Fish processing plant design differs from the average food processing plant design, as fish and seafood processing have different needs and require extra care.

Choosing the Right Fish Processing Plant Design and Layout

The right fish processing plant layout ensures a safe, organized, and sanitary facility. To meet these goals, a facility should ideally have a unidirectional flow that follows the processing steps. This means that the plant setup should begin with the receiving area (where the raw product is received), continue through the various steps for preparing and processing the fish, and end with the packaging and dispatching of the finished products.

What Goes into a Fish Processing Plant Design and Layout?

There are many different components necessary for a fish processing plant. Some of the most important aspects include the following:

Air Conditioning System

Temperature is key to maintaining the plant's temperature, which is required to maintain a minimum temperature of 22 to 24ºC throughout the facility, from pre-processing to packaging. Maintaining this temperature is critical for ensuring the safety and quality of the final product. Facilities must have high-quality air conditioning systems in place throughout the processing area.

With these high-efficiency systems, it is important to account for increased humidity, as it can lead to mold and bacteria growth if left uncontrolled. To avoid these issues and maintain standards, you need a system that will:

- Maintain a consistent temperature that reduces ice melt and heat gain

- Help minimize employee fatigue

- Eliminate condensation on the ceiling and other surfaces

Cold Storage

Cold storage is an essential part of a fish processing plant and deserves special attention in the design process. The cold storage area has three parts: the main storage area, the anteroom, and the material dispatch area. While many storage systems are available, not all are ideal or suited for a fish processing plant.

Some of the systems to consider for the main storage area include:

- Single deep racking

- Double deep racking

- Mobile racking

- Pallet shuttle systems

The anteroom needs to provide enough space for workers and materials to move freely and maintain a temperature of 7ºC to 10ºC. Anterooms also need proper ventilation to prevent condensation from forming and need to have an effective air-lock system in the docking area.

Finally, with the docking area, you want a space large enough for a dock leveler to operate easily. The height and position of it should allow them to easily load and unload refrigerated racks and containers in the dock.

Drainage

Another component of fish plant design and layout that is often overlooked is floor drainage. Fish processing plants use more water than other facilities, from the water used for processing to the water from bathrooms, cleaning, and other areas. Water can be left standing without proper drainage, and can lead to bacteria growth, contamination, and pest infestations.

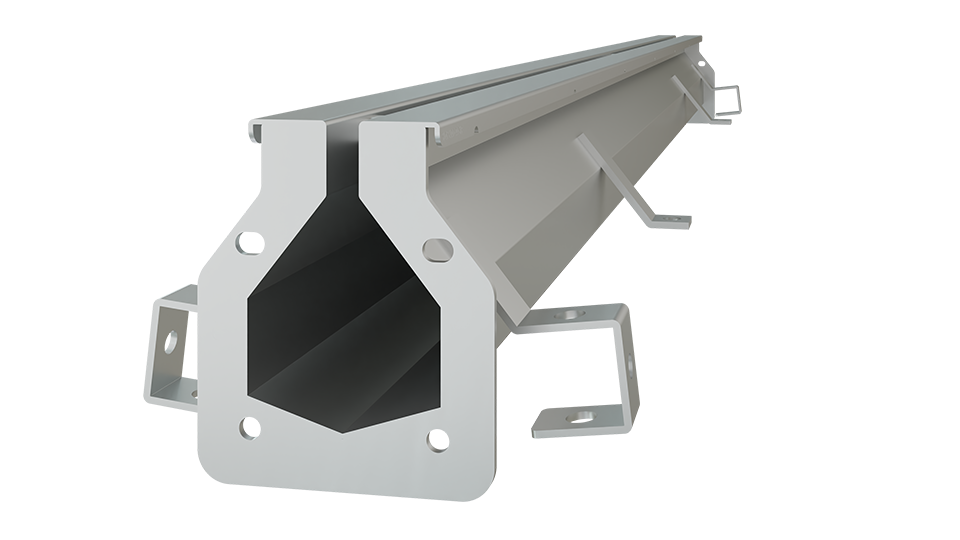

FoodSafe Drains is a company that specializes in food-safe drainage systems constructed with T304 and T316 stainless steel, fully NSF/ANSI/3-A certified designs to ensure there are no sharp corners that can potentially harbor bacteria. They have many systems, but the FoodSafe Slot Drain and Trench Drain are their larger main floor systems.

The FoodSafe Slot Drain is an open subsurface system with a small channel opening that eliminates any need for a drain cover. It comes pre-sloped and pre-assembled, for easier assembly and to eliminate more bacteria-harboring seams. It has a forklift-rated design and is compatible with additions like clean-in-place (CIP) technology and the FoodSafe catch basin with a magnetic, tamper-proof lid and strainer basket.

The FoodSafe Trench Drain is the other main system, with round, flat, and v-shaped bottom options. It is fitted with a 1-inch thick stainless steel grate that is forklift-rated and has a magnetic, tamper-proof strainer. Like the FoodSafe Slot Drain, it is compatible with CIP technology and the FoodSafe catch basin.

The FoodSafe Trench Drain is the other main system, with round, flat, and v-shaped bottom options. It is fitted with a 1-inch thick stainless steel grate that is forklift-rated and has a magnetic, tamper-proof strainer. Like the FoodSafe Slot Drain, it is compatible with CIP technology and the FoodSafe catch basin.

Equipment

A facility's equipment goes hand-in-hand with layout and design. This includes sorting machines, freezers, canning machines, smokers, and more. Each piece serves specific purposes and should be placed in the appropriate sections to ensure everything possible to avoid cross-contamination. Having the right safety equipment in place for potential emergencies is also essential.

Take The Time to Plan Your Fish Processing Plant Drainage with FoodSafe Drains

Like any food plant, fish processing plants require time and care to ensure their design and layout consider safety and sanitation concerns. The design and layout of these facilities are vital for creating products safe for consumption. Every detail matters when creating a fish processing plant, including things often overlooked, like a floor drainage system.

Contact us today to learn more about FoodSafe Drains, the systems they offer, and how they can help create a safe, sanitary fish processing plant design and layout.