Ice cream is enjoyed by people of all ages, and being a dairy product, the finished product is at risk of bacterial contamination within the production facility.

Pathogens like listeria, campylobacter, and salmonella are always a worry in a dairy production facility, so here are some considerations to help ensure that your consumers stay safe and that production is anything but a rocky road.

1. Clean All Ramps and Carts

Like all food facilities, the key to preventing contaminated ice cream is through proper cleaning and sanitation practices. While it is common sense to clean some areas, others are easy to overlook, especially if they aren't seen as essential to the ice cream making process. Ramps, rampways, and carts all require regular cleaning and drying to prevent bacteria growth that can spread to transported products.

Even ramps around freezer or refrigerator storage require sanitation, as bacteria will not die from the cold; it will only go dormant for a short while. It is only through proper sanitation that you can eliminate bacteria.

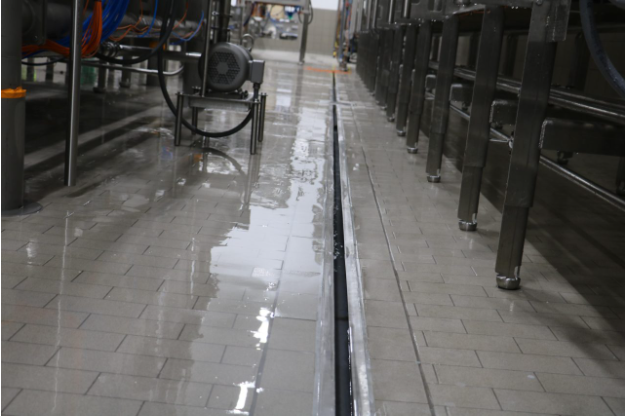

2. Install a Floor Drain System

Floor drains also are effective at preventing ice cream bacterial contamination. These systems help manage a facility's wastewater, trapping the dirty water in the drain, and preventing bacteria from spreading and contaminating products within the facility. They also create a safer work environment by keeping floors free from standing water, which can pose a slipping hazard to workers.

Systems like Slot Drain's 10,000 Series model is a grate-free system made from bacteria-resistant, food-grade stainless steel. This alone will not eliminate bacteria in ice cream, however, it will catch and contain it safely, ensuring it cannot spread to other parts of the facility. Slot Drain can also withstand cold temperatures better than other systems on the market, making it an ideal companion for ice cream production facilities. A heavy-duty load capacity and clean-in-place capabilities, keep the system easy to maintain and will significantly reduce the risk of ice cream contamination.

3. Color Code Cleaning Tools

Cross-contamination is one reason listeria in ice cream can occur. It isn't just a matter of using the same mixing tools at different stages of the ice cream-making process; cross-contamination can also occur when mixing cleaning tools. To prevent listeria or salmonella, ice cream facilities should color code all cleaning brushes, buckets, and other tools.

Ideally, one color should denote tools used to clean surfaces that come into contact with pasteurized foods. A different color should be reserved for nonfood-contact surfaces and a third color for surfaces that come into contact with raw milk products. A final color should be dedicated to tools used to clean the floor drain system.

4. Ensure Ingredients Are Properly Stored

An improperly stored ingredient can lead to contaminated ice cream. Since ice cream involves cold products, it is critical to ensure the refrigeration

and freezer systems are maintained at the appropriate temperatures. If ingredients, such as the milk or cream become too warm, bacteria can begin to grow. If the issue isn't caught, it can lead to a batch of contaminated ice cream.

It is also wise to consider separate storage units for raw ingredients and finished products. If unpasteurized milk products are near finished ice cream, there is a possibility that it will result in ice cream bacterial contamination. This could lead to serious consequences if the contaminated product were to reach the public.

5. Keep Equipment Cleaned and Sanitized

An important step in avoiding ice cream contamination is to keep all the equipment clean and sanitized. This doesn't just mean the equipment used to make the ice cream; it includes the refrigeration and freezer equipment, the HVAC system, all contact surfaces, drains, and other tools within the facility, no matter how small they may seem. Missing one area can lead to the potential of bacteria in your ice cream.

Ways to help cut down on the risk include investing in stainless steel materials everywhere possible. Stainless steel is a bacteria-resistant material that will be better able to handle the strong cleaners used to sanitize food facilities. You should also consider installing equipment that offers clean-in-place compatibility, which can significantly cut down on the time it takes to clean and sanitize everything.

6. Heat Ingredients to the Right Temperatures

Salmonella and listeria in ice cream can occur for many reasons, but one that can be overlooked is not heating ingredients to the appropriate temperature. Without the right shell and tube heat exchangers, a facility will not adequately kill the bacteria in the product. If bacteria remains, it could mean salmonella in the ice cream, but workers wouldn't know until it is too late and the company has to face the consequences.

Talking to a heat exchanger professional can help to ensure you buy the right product for your facility so that you can rest assured your ice cream is getting heated to the correct temperature. You also will want to service it and the other equipment in your facility regularly to ensure they are always in good working order.

Preventing Ice Cream Contamination

Ice cream contamination isn't common if you set up the proper safeguards, but when it happens, it’s cause for alarm — and rightly so. Ice cream facility managers must educate themselves on ice cream contamination, including how it occurs and how to prevent it. These six steps are just a starting point, but they are critical in creating a safe, clean facility where contamination can be prevented. Following these guidelines will keep your workers and your product safe and ensure you have a positive reputation with the public.

Contact the drainage experts at FoodSafe Drains today for more information about creating a safer ice cream manufacturing facility.