According to the CDC, an estimated 1,600 people per year get sick from listeria contamination (listeriosis), resulting in an average of 260 deaths per year. Listeriosis is most likely to affect pregnant women, newborns, older adults, and those with weakened immune systems.

It is a serious problem that only continues to grow in severity as food production managers and employees work to ensure that their facilities are kept clean and properly sanitized. A facility's drainage system may be overlooked as a contamination risk, but it is actually one of the most important things to consider when attempting to prevent listeria contamination.

Here's what you need to know.

WHAT IS LISTERIA?

Listeria is a genus of food-borne bacteria, most commonly found in the form of Listeria monocytogenes (L. monocytogenes). It acts as a parasite in humans who eat contaminated food, causing listeriosis, which is a relatively rare disease that may present with fever, fatigue, muscle stiffness, and flu-like digestive symptoms.

The "overt form" of listeriosis has a case-fatality rate of roughly 20%, making listeria a severe threat to food safety and prevention all the more important.

WHERE DOES IT COME FROM?

The L. monocytogenes bacteria grows in all types of environments, but is primarily found in moist environments, such as soil, water, sewage, and even decaying vegetable matter, as well as uncooked meats and seafood. The bacteria can also survive and grow in cold and even freezing temperatures, which highlights an ever-present risk of cross contamination throughout a food processing facility

What makes listeria particularly dangerous is that it is difficult to detect with scientific testing. Contaminated foods generally do not smell or taste any different, and listeria can be incredibly adaptive, making it all the more dangerous.

LISTERIA AND FLOOR DRAINS

Listeria thrives most in wet, dark places, which means that it is commonly found in places like floor drains within food processing facilities. If left unchecked, the listeria found in floor drains can make its way around a food processing facility in a number of ways:

- Employees can walk over contaminated drain grates and transfer the bacteria on their shoes.

- Fruit flies, other insects, and other pests can cause listeria to spread to any part of a facility.

- High-pressure spray while cleaning certain types of drains can force the bacteria in to the air. Listeria can also linger on cleaning equipment that is not properly sanitized after cleaning out the drains.

- A clogged drain can allow bacteria to grow in standing water, creating the potential for splashing and overflowing when more liquid enters the drain channel. This can spread contaminated wastewater throughout a facility.

PREVENTING LISTERIA IN DRAINS

Since it is easy for listeria to spread due to ineffective floor drainage, facility drainage design should be carefully considered from the start. Whether you're installing drainage in a brand new facility or looking to retrofit a more effective drainage system, the type of drains you choose, including the material they're made from, can have a drastic impact on preventing bacterial contamination.

Floor drains should feature a design that makes them easily accessible for cleaning, and they should be manufactured using materials that help to prevent the growth of bacteria, such as stainless steel. Additionally, any floor drains should eliminate the possibility of standing water, where listeria can easily multiply.

If drains become backed up and flood over into any food preparation areas, food production must stop immediately. Stopping production until the problem is solved and the mess is cleaned will help prevent any listeria contamination from spreading to products.

Prevention is key, however, as any disruption due to having to clean up contaminated water or waste will almost certainly result in downtime and losses.

STRICT CLEANING PROTOCOLS ARE IMPERATIVE

Another important requirement the FDA has outlined for listeria prevention is ensuring that all employees, in both maintenance and food production, follow the same cleaning protocols. Ensuring that everyone follows strict hygiene measures will help to reduce the spread of listeria and other bacteria significantly, and should contamination occur, it should then be easily traceable.

Employees who clean the drain systems should not touch or handle food in any capacity without changing their uniforms and protective gear, thoroughly washing and sanitizing their hands, and putting on clean gloves. All of this is essential, as listeria can cling to their clothing and end up spreading if they do not take the correct precautions before handling food products or other equipment.

CHOOSING THE RIGHT DRAINAGE SYSTEM

To ensure the safest possible food production, the FDA has defined specific requirements that a floor drain needs to meet in a food processing facility. A drainage system needs to be sanitary, easy to clean, and capable of heavy flow rates to prevent flooding.

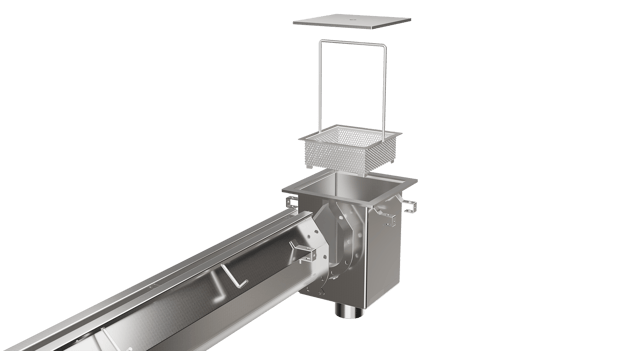

FoodSafe Drains offers low-profile and high flow rate drainage systems for the food and beverage industry that meet the specific, strict FDA requirements and recommendations. The slot drain system is unique in its design, as it is a linear system with a slim channel opening that doesn't require a grate.

It features a bacteria- and corrosion-resistant food-grade stainless steel body that arrives fully assembled and ready to install. Stainless steel is also helpful in preventing the formation of biofilm, since it is nonporous, and the slot drain features a radiused bottom, offering no place for bacteria to cling to and grow.

The design also prevents liquids from splashing out of the trench, which reduces the potential for cross-contamination and slipping hazards. Our slot drain systems come pre-sloped, which encourages water to flow toward the catch basin, preventing standing water of any kind.

HOW THE SLOT DRAIN SYSTEM SHINES

The FoodSafe Drains slot drain is very easy to clean, with specialized cleaning instruments, clean-in-place (CIP) considerations, and even self-flushing options available to make cleaning and sanitation a breeze.

The slot drain system is incredibly durable and can handle flow rates of up to 27 gallons per minute (GPM) per linear foot.

YOUR CONSUMERS DESERVE A BETTER DRAINAGE SYSTEM

The slot drain system is the best possible drainage system for helping to prevent listeria contamination stemming from drainage. The pre-sloped design and stainless steel construction go hand in hand in preventing bacterial accumulation, and the narrow slow opening helps to prevent trips and falls, as well as splashing water during cleaning.

To learn more about why the FoodSafe slot drain is ideal for your facility, contact one of our drainage experts today or download our drainage design considerations document.