Everyone loves bakeries, but most folks have no idea what goes into creating a great bakery. Bakeries are required to abide by the same food safety requirements as all other food industry facilities and establishments. This means they need to ensure a safe, sanitary space, including a specific setup. There are detailed requirements for everything, including the flooring. Here is what you need to know about bakery flooring and other essential parts of creating a clean, sanitary, and successful bakery.

WHAT IS BAKERY FLOORING IMPORTANT?

Bakery flooring is crucial to the overall facility. It helps create a safe, sanitary facility that prevents the growth of mold and bacteria, which could ruin products and cause contamination and foodborne illnesses. Unlike residential kitchens, there are strict guidelines for bakery flooring selection that owners must abide by.

REQUIREMENTS FOR GOOD BAKERY FLOORS?

You can’t just use any flooring for a bakery. There are many specific requirements that the flooring must meet in order to be acceptable. Some requirements include:

Slip-Resistance

Eggs, water, flour, butter, and oil are all ingredients that can create a slippery surface if they fall on the floor. Beverages and fallen treats in the customer area can also create a slip hazard. Falls can be minor, but they can also result in serious injury, which could bring legal troubles. This makes it crucial that floors have a slip-resistant coating to help prevent falls.

Durability

Running a bakery isn't cheap; the costs add up from the cost of equipment and ingredients to the rent for your space. Choosing a durable, long-lasting floor material will help reduce costs. The floors will need to be able to withstand wear and tear from daily traffic, varying temperatures, acidic ingredients, and the various cleaning chemicals used at the end of each day.

Ease of Maintenance

There is enough to clean in a bakery as it is. You don't want to have to scrub floors at the end of the day too. Choosing a material that is easy to maintain will lessen your staff's daily cleaning workload.

BEST OPTIONS FOR BAKERY FLOORS

Here are some bakery flooring options worth considering:

Commercial Kitchen Tiles

Tiles are an option that provides a nice, traditional aesthetic. Commercial kitchen tiles are designed specifically for commercial kitchen spaces and can be ceramic, porcelain, or natural stone. The material you choose depends on the needs of your kitchen. Tile is durable, slip-resistant, easy to maintain, and cost-effective.

Floor Coatings

Floor coatings are an easy, popular option, typically laid over concrete floors.

Epoxy Coatings

Epoxy floor coatings are another option that meets the requirements for bakery flooring. They are resistant to acids and alkalis and can be made slip-resistant by adding anti-skid additives and curing the floor quickly for less downtime. Novolacs, a specific type of epoxy, provides higher chemical and heat resistance than some other epoxy coatings.

Epoxy coatings can be customized and made more aesthetically pleasing by adding aggregates, like quartz or marble, into the mixture before pouring.

Urethane Coatings

Urethane coatings cost more to install but will last longer than other flooring options. Additives can be used to create a blend resistant to thermal cycling or slip resistance or to add decorative touches. Like epoxy coatings, it cures quickly to minimize downtime.

Polyurea Coatings

Polyurea coatings are highly impact-resistant and meet the UL NSF/ANSI 61 Standard for Drinking Water Systems and Components. They cure the quickest of all the coatings and can withstand extreme temperatures.

Other Factors That Go Into a Bakery Besides Flooring

It isn’t just the bakery flooring you need to consider. There are several other factors that you need to consider that go into creating a clean and safe bakery, including:

Designing the Right Layout

Although even the best bakery flooring can help, choosing and designing the right layout is critical for bakery kitchens!

The layout should flow based on the production steps, from raw ingredients to finished products. This will help prevent contamination or missed steps, and ensure that employees don't run into each other.

You also want to consider adding cleaning stations at strategic points for employees to wash their hands or to clean up messes quickly.

For the front of a bakery, there are other considerations. Bakeries aren't overly large spaces, so planning your layout to maximize the available space is essential. Displays should catch customers' eyes as soon as they walk in and be enticing, and tables should be spaced so that customers can sit and move around comfortably. You also want to create a flow, like going from right to left, to avoid congestion by the counters. Consider different layouts and try to visualize what works best in your space.

Use High-Quality Equipment

You need the right equipment for the bakery to succeed. While it is more expensive, especially for new bakeries, investing in the best equipment, from mixers to cold storage units, is vital. High-quality equipment will last longer and be less likely to break down, which helps save money in the long run.

Drainage

Efficient floor drainage is another vital part of a bakery. A floor drain system works with the flooring to maintain a safe, sanitary space and prevent bacteria and contamination from taking root. Like with flooring, drainage systems must meet specific requirements: they must be made of a nonporous material like stainless steel, and they must be durable, easy to clean, and resistant to chemicals, just to name a few requirements.

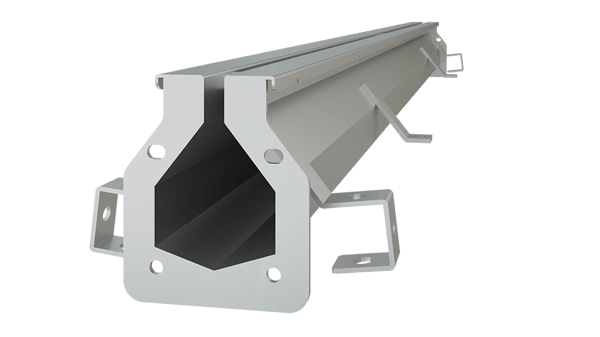

The FoodSafe Slot Drain is a new approach to the traditional trench drain that eliminates grate covers. It uses food-safe stainless steel and is NSF/ANSI/3-A certified.

The slim, linear design makes it more subtle than traditional systems, while the open design allows easy cleaning while preventing objects from falling inside. The stainless steel is chemical, temperature, and odor resistant to easily handle everything that happens in a bakery.

The 6,000 PLUS Series is Load Class C-rated, and the 10,000 Series and 6,000 Series PLUS-R are E-rated. Both offer clean-in-place capabilities to make cleaning and maintenance very easy.

Rules and Employee Expectations

You can have the perfect layout, the right floors, and a FoodSafe Drain, but something can still go wrong without rules in place for employees. Rules provide clear expectations for employees so that they know how to meet their goals.

There should be rules about how to handle the production of products, how to store goods, cleaning procedures, and an outline of employee hygiene expectations. Once you have the rules laid out, you need to enforce them and ensure that everyone is following them, and take the time to train new and old employees and review the rules regularly with the entire staff.

THE FOUNDATION OF A GOOD BAKERY IS QUALITY BAKING FLOORING

So much goes into creating a bakery, from finding a suitable building to perfecting all of the delicious recipes.

One of the most critical parts, however, is the bakery flooring. Simply put, it holds all the equipment, counters, tables, and chairs and provides a safe, clean walking surface for employees and customers.

The floor shouldn’t just support your drain system, which is just as critical; it should also help keep your bakery free from bacteria and contamination.

Contact us today to learn how bakery flooring and drainage systems work together and what makes the FoodSafe Slot Drain the perfect drainage solution.