With the world's obsession with beer, it makes sense as to why there are so many brands available on the market–and why new ones keep coming. This also means that breweries are becoming more commonplace. However, you can't just call a building a brewery and start making beer–you need the right setup. From the equipment down to the floors, every aspect of a brewery is important. Here's what you need to know:

A Brief Look Back at Brewing

Commercial brewing dates all the way back to 3500 BC in ancient Mesopotamia. However, in those times, there were no large breweries to speak of. Instead, the beer was brewed in homes and was referred to as the "cottage industry" method. It wasn't until later on, that large-scale brewing operations began popping up across the world, brewing and selling large quantities of beer.

As the popularity of beer continues to increase, you can find breweries of all sizes, from large commercial ones to local microbreweries. While each one has its differences, the setup is the same for all of them.

Understanding the Setup of a Brewery

A commercial brewery, big or small, requires a lot of equipment. The equipment does everything, from cracking the grain to bottling and capping the finished product.

Without a doubt, the most recognizable parts of any brewery are the stainless-steel kettles. While the largest size is what companies tend to use to brew the beer, smaller breweries may use a smaller kettle called a mash tun for this step. For lager-style beers, there is a third type of kettle used, called a lauter tun. Regardless of which kettles a company uses, they all have similar construction: they are vented using stacks that carry steam out of the brewery and into the open air.

Once the kettles have brewed the beer, it doesn't mean the production process is over. After the beer has passed through the kettles, it is cooled and pumped into another machine called a fermenter, and it is during this step that beer really becomes beer. For sanitary reasons, fermenters are airtight vessels that only allow carbon dioxide to escape, which builds up during fermentation.

Once the beer has been fermented, it is transferred to an aging tank, where the beer continues to ferment more. After a set amount of time, it is moved to a finishing tank, where the final product is prepared for bottling and shipping.

Where Does Brewery Flooring Come In to Play?

To the ordinary person, a floor is just a floor; something to walk on that may or may not be aesthetically pleasing. However, in some industries–including food and beverage production–a floor is much more. Flooring is just as important as the rest of the facility and is not to be taken lightly. These industries cannot use any flooring they want because there are specific legal standards they have to meet; otherwise, they will not be allowed to function. Some of the many requirements for brewery flooring include:

- A brewery's floor, for hygienic purposes, needs to be made of a non-porous material and should not have any gaps or cracks. Aside from that, it should feature antimicrobial properties, which will help prevent the collection and growth of bacteria and other harmful organisms.

- Brewery floor coating also needs to be moisture and chemical resistant, so it doesn't degrade rapidly with constant exposure to wet environments and corrosive materials.

- Any flooring used for breweries needs to work well in both wet and dry conditions, due to the nature of breweries. Being able to withstand such conditions without damage is vital.

- Floors should offer skid resistance as well. Otherwise, it can lead to workers and visitors falling and becoming injured.

- The lower the environmental impact a brewery's floor has, the better.

The Different Brewery Floor Coatings

The regulations listed above are just some of the FDA-enforced rules that breweries are expected to follow when it comes to flooring. The most common type of brewery flooring is a concrete floor, with a special coating like one of the following:

1. Epoxy

An epoxy coating is the most well-known floor coating option. Epoxy is a thick, super-glue-like adhesive that helps stick materials together and works well on a brewery floor. It is a popular option because it is cost-effective, durable, and easy to install. However, it is not long-lasting and will need to be redone as it wears down in order to maintain its effectiveness.

2. Urethane

Another floor coating option is urethane, which is especially popular for food and beverage facilities. It is a popular option because it meets all of the FDA floor requirements: it is high-quality, long-lasting, skid-resistant, and hygienic. This type of floor coating can also be used to fill cracks easily, so there is no chance of bacteria getting trapped.

3. Methyl Methacrylate (MMA)

When time is money, breweries and other industries want floors that they can install quickly and get to work. Because of that, MMA flooring has become a popular option since it cures faster than other options. It also has all the same benefits of the other flooring options already mentioned. However, there is one difference to note: MMA floor coatings come in a wide range of colors, and you have the option of additives like quartz crystals to make the floor more aesthetically pleasing.

4. Metallic Epoxy

Metallic epoxy has the same benefits of regular epoxy flooring; it is just in appearance where they differ. While regular epoxy is simple and plain, metallic epoxy has a unique look and texture, appearing glass-like. This makes it a popular option for breweries that do tours and tastings, as it is more aesthetically pleasing. Metallic epoxy can also be treated to add additional skid resistance, ensuring everyone's safety.

Cleaning a Brewery and Drainage Considerations

Even with the right setup and flooring in a brewery, it won't matter if it isn't kept clean and sanitized. There are many ways to clean, and the best option will vary for each brewery. However, something important to keep in mind is that cleaning and sanitizing are two different steps. Cleaning is the first step, which ensures there is no dirt or residue on the equipment (and anywhere else) while sanitizing happens after cleaning in order to thoroughly kill any remaining bacteria.

But, cleaning and sanitizing shouldn't be your only concern for maintaining a clean brewery. You also need to have the right drainage system in place to manage wastewater and reduce overall water usage, maintenance costs, and utility expenses.

Knowing what system to choose can be difficult with so many options on the market. One option is pot drains, which is a cost-saving option since the individual drains cost so little. However, because pot drains require the floor to be sloped on all four sides, and each drain requires plumbing, installation costs can become high. That doesn't even consider the costs of maintaining them. All of these factors, particularly the sloped flooring–which creates an uneven surface–make pot drains less than ideal.

There are also trench drains, the most common and next best option. Trench drains can come with or without a grate covering and are sloped in a single direction, to the drain channel. While grated systems allow you to see objects caught in the drain, grates are heavy, cumbersome, and rather fragile. Removing them incorrectly can result in injury, and if they break from too much wear or weight, they become a serious safety hazard.

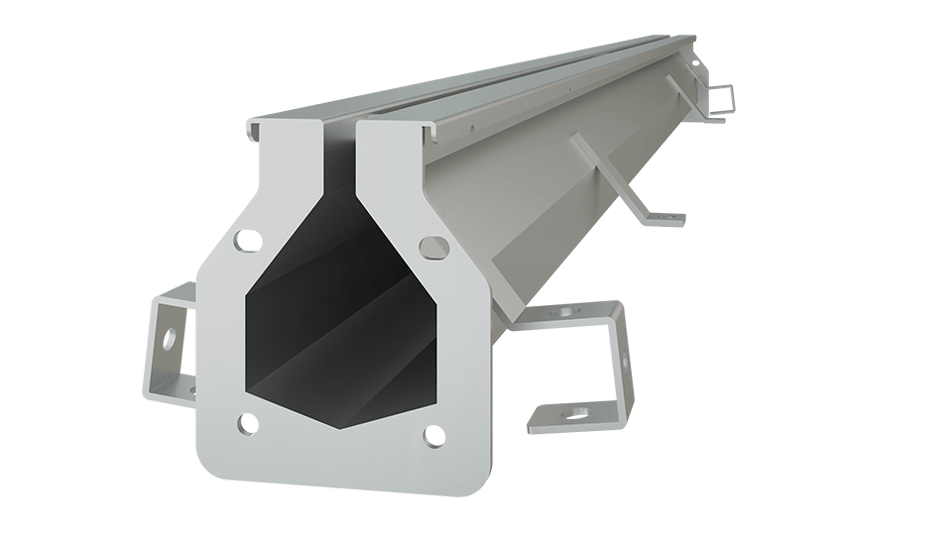

There are grate-free trench drains produced by Slot Drain. Slot Drain offers the same benefits as the traditional grated system, without the concern of grate covers. It is a seemingly small, but significant difference that allows Slot Drain to be far more durable: their drain systems have a Class F load-bearing capability which creates a safer system. Due to the small slope used by these systems, water runoff travels to the drain channel easily. In addition, Slot Drain is a sanitary system, constructed from food-grade stainless steel, that is very easy to clean and maintain.

Breweries have become increasingly popular, not just for the products they offer, but as a hang-out space. Most folks have no idea just what goes into running a brewery. It is labor-intensive, and every detail matters, from the equipment down to the flooring and drainage system. The only sensible option when it comes to drainage is Slot Drain, which is more effective and can help you run a cleaner, safer, and more cost-effective brewery operation.