For food processing and manufacturing facilities, cleanliness is vital. While, obviously, the equipment and floors should be kept clean, the facility floor drain system is a critical area that also needs to be kept clean and sanitary.

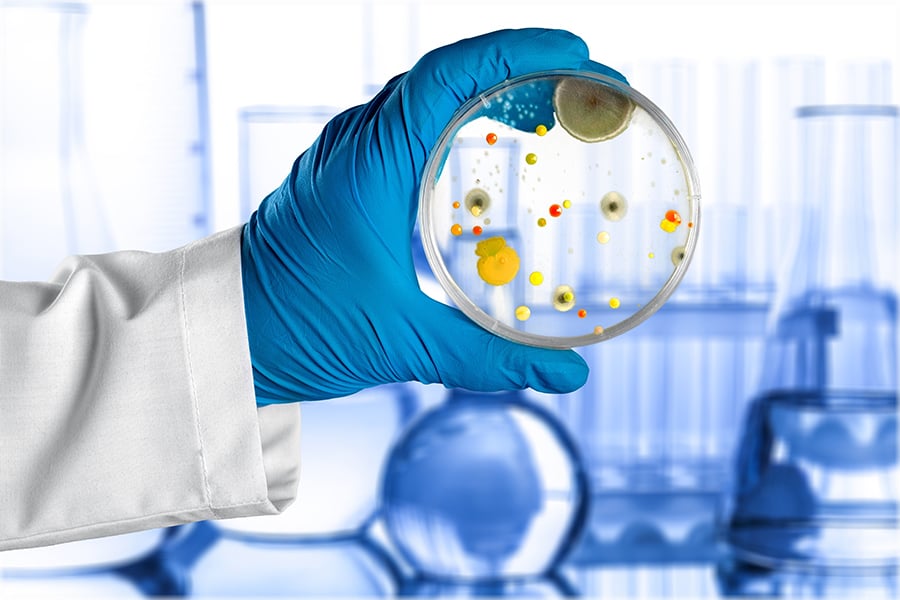

Drain systems in facilities are sometimes overlooked or forgotten, but they tend to be a major culprit of bacterial growth and contamination. Dangerous pathogens like listeria, salmonella, and E.coli can live and grow in a dirty drain and eventually spread, leading to contamination of more areas of your facility.

There is no escaping the importance of clean drainage for food manufacturing facilities. Here are some tips to help keep your drains squeaky clean.

CLEANING THE FLOORS

Just like drain systems and any other part of your food facility, floors can play host to all types of harmful bacteria and contaminants. Workers can send these harmful pathogens into the air as they move around, causing them to move to other areas of your facility, leading to widespread contamination issues.

Cleaning your facility's floors is a multi-step process. First, sweep up any dust or debris. If left untouched, these particles and debris can cause problems like project contamination and the attraction of insects and rodents. By sweeping, you also provide a cleaner surface for applying cleaning solutions, which allows them to work more efficiently.

After sweeping, you can apply cleaning solutions according to the instructions on the container and the regulations imposed on your facility. After rinsing off the solution, you can sanitize the floor to finish the cleaning process.

CLEANING THE DRAIN SYSTEM

Once the floors are clean, you should tackle the drain system to eliminate harmful bacteria that can contaminate your facility. Drain cleaning must be done thoroughly to ensure every bit of debris is removed and the system is immaculate. The cleaning process can vary depending on the system.

Traditional trench drains have a heavy grate that has to be removed before cleaning, and you have to remove the strainer and quat block, if present. These parts all require scrubbing and sanitizing before they can be returned to the drain.

After these parts are taken out, you remove any large debris from the drain channel, which prevents blockages, so water can flow smoothly through the system. Next, you must rinse the channel with warm water and a cleaning agent to remove any remaining debris.

A drain brush can be used to scrub the drain walls to ensure every bit of debris is removed. Then, you do a final rinse before applying a sanitizing solution. Finally, you put the strainer and grate back in place, and the job is done.

For safety, you may consider cleaning your drain cleaning tools to remove any bacteria, so they are clean for the next time.

A DRAIN SYSTEM WITH LESS WORK

Cleaning a traditional drainage system can be time-consuming. Handling the grate covers can lead to injury if workers aren't careful, and a grate leaves nooks and crannies between the separate parts where bacteria can harbor and grow, making the systems less than ideal.

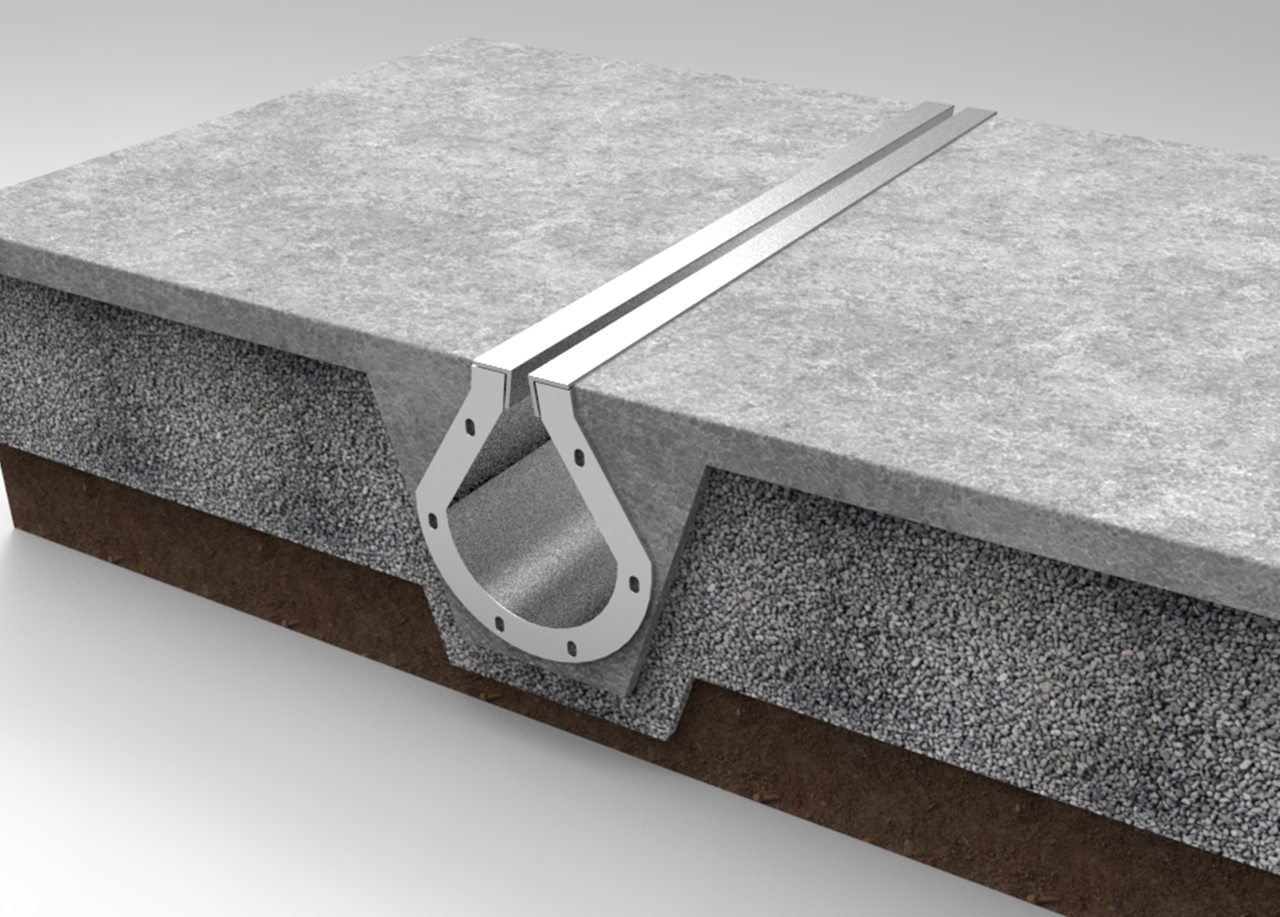

Fortunately, there is a new trench drain system that is changing things.

The FoodSafe Slot Drain is an ideal option for sanitary, food-safe drainage in food manufacturing facilities. This linear system uses food-grade stainless steel, which is resistant to corrosion, temperature, and bacteria.

What really makes these systems stand out from traditional trench drains is their grate-free design. The slot drain’s channel openings are slim enough to allow water and small debris to pass through, but nothing else.

Since the slot drain is a grateless system, cleaning it is incredibly easy and can be done in half the time of traditional systems. One method uses a brush and paddle system to clean drains manually. You push the debris with the paddle towards the strainer basket, which you will then empty before rinsing the channel and apply a sanitizing solution.

Another option is the FoodSafe Flush-Flo system, which allows you to hook up a water line to your drain for an automated cleaning process. It is still, however, a good idea to use the brush and paddle method to ensure nothing is left sticking to the channel walls before rinsing and sanitizing.

Having a clean food facility is not just required by law but is also vital for success. It is especially critical to ensure clean drainage for food manufacturing facilities; otherwise, bacteria and contamination will run rampant. To make the cleaning process easier and more efficient, consider a drain system like the FoodSafe Slot Drain, which is easy, safe, and cost-effective.

THE BEST FOOD MANUFACTURING FACILITY DRAIN

Installing a slot drain system from FoodSafe Drains will reduce maintenance and cleaning needs while protecting worker and consumer safety and improving efficiency. When it comes to the long-term health of your manufacturing facility, the choice is clear. Upgrade to a slot drain system today and discover how helpful a better drainage system can be.