Seafood refers to any form of sea life marketed for human consumption. According to the Food and Drug Administration (FDA), this includes commercially farmed freshwater, saltwater fish, and shellfish. While all of these are considered seafood, they are different, which means there are differences in the processing methods. A shellfish processing plant will not have the same layout and design as a processing plant for fish.

Here is what you should know about shellfish processing and what goes into creating the perfect plant.

What is Considered a Shellfish?

As the name implies, shellfish is a seafood category with a shell or shell-like exterior. There are two categories of shellfish: crustaceans which include shrimp, crayfish, crabs, and lobster, and mollusks, which include clams, scallops, oysters, and mussels.

Typically, they are found in saltwater and can be prepared in many different ways.

The Shellfish Processing Process

Seafood processing involves multiple processors. The primary processors are responsible for shucking, cooking, and removing the edible meat from the shell. From there, edible portions are packed and distributed as fresh, refrigerated products or frozen prior to distribution.

Secondary processors combine fresh or frozen shellfish with other ingredients to create products like meals and appetizers that are sold in stores and restaurants.

The Importance of a Layout and Design in Shellfish Processing Plants

Regardless of the product, the layout and design of a facility are vital for a clean, sanitary, and organized facility. Seafood has a higher microbial contamination risk, which only increases during processing. Common pathogenic microorganisms found in seafood are Listeria, Salmonella, Acinetobacter, Moraxella, and E. Coli. A proper layout will have a unidirectional flow that will minimize the risk of bacterial contamination and keep unprocessed shellfish away from the final products. Maintaining a unidirectional flow will also prevent other contaminants, like shell fragments, from ending up in the finished product.

Components of a Shellfish Processing Plant Layout and Design

There are many components and details to consider when creating a shellfish processing plant layout and design:

Air Conditioning

Like all seafood, shellfish must remain cold in order to keep it safe and minimize pathogenic risks. A high-quality, efficient air conditioning system is essential to maintain the appropriate temperatures throughout the processing area. Temperatures should be in the range of 22º to 24ºC in these areas.

With cool temperatures comes increased humidity issues, which can lead to bacteria and mold growth if left unmonitored. To avoid this, you will want a system that can maintain cooler temperatures while keeping the relative humidity between 60% and 70%. The ideal air conditioning system will:

- Reduce the melting of ice and heat gain by product

- Help reduce employee fatigue

- Eliminate unwanted condensation on surfaces, especially the ceiling

Equipment

The equipment in a plant is equally important in the layout and design of a plant. When considering your equipment, you should choose energy-efficient, hygienic pieces with the lowest product weight loss. Notable equipment includes water chillers, ice-making machines, conveyor belts, and mussel weight baggers. When choosing equipment, it is important to choose pieces that fit comfortably within the facility while also allowing space for employees to move around and for service work on the equipment.

Cold Storage

Cold storage, like the air conditioning system, requires special attention. This is the area where the finished products are stored before they are shipped. It is generally broken into three sectors: the storage area, the anteroom, and the dispatch area. There are many styles of storage systems within the seafood industry, including:

- Mezzanine floor or multi-tier flooring

- Drive-in racking

- Single deep racking

- Double deep racking

- Mobile racking

- Pallet shuttle systems

Each has its advantages and disadvantages to consider. The system that works best for you will depend on your needs and preferences.

An anteroom will require adequate space to allow for the free movement and flow of employees and materials while maintaining a cool 7º to 10ºC. The dispatch or docking area also requires a reasonable amount of space to allow a dock leveler to operate easily. It should also have an appropriate height and position to allow employees to easily load and unload containers on the docks.

Drainage

Floor drainage, often overlooked, is another vital component to a shellfish processing plant. With the excessive amounts of water used in seafood processing facilities, the right system is necessary to move the water away and minimize the risk of bacteria growth, pests, and contamination. Floor drains help manage processing waste and wastewater from other areas, like restrooms and employee break areas.

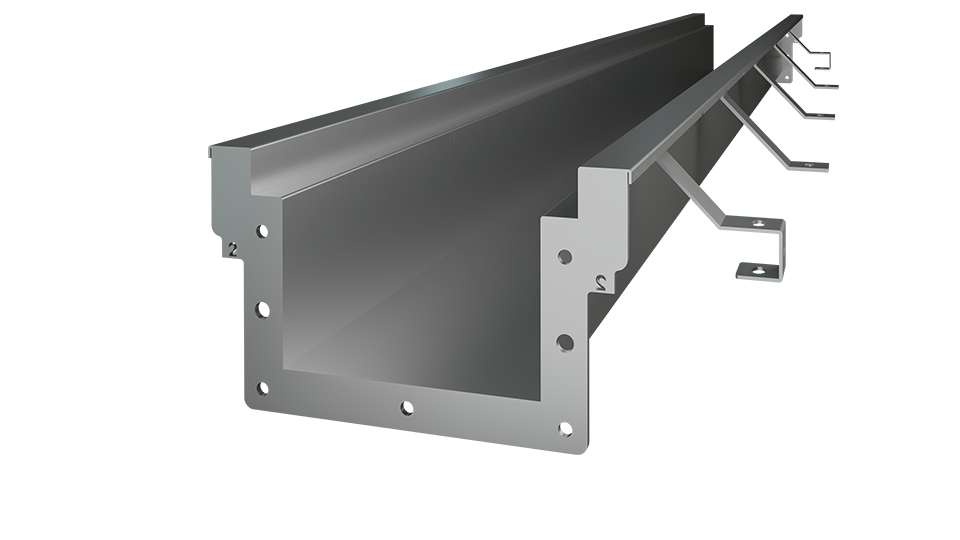

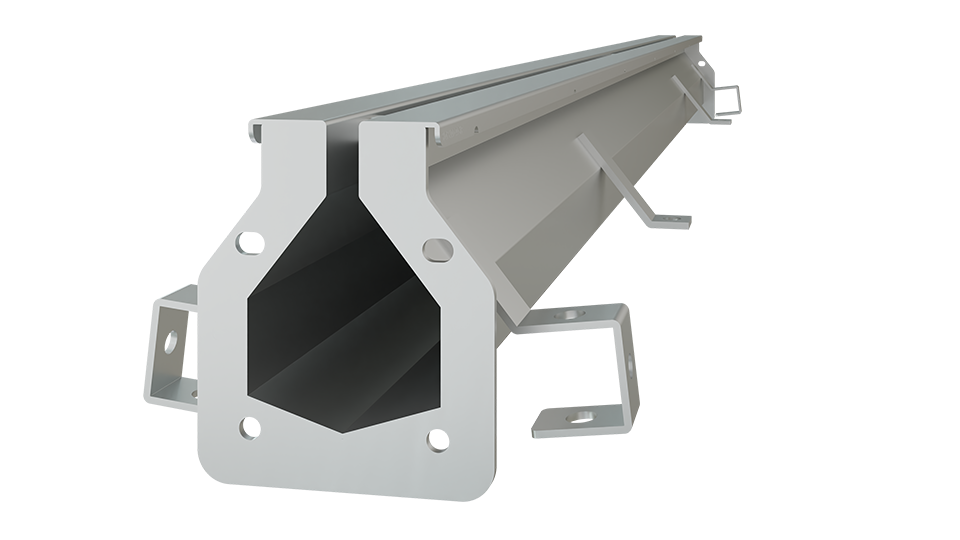

FoodSafe Drains has numerous systems with NSF/ANSI/3-A certification that feature T304 and T316 stainless steel in their construction. The design ensures no sharp corners or seams that could harbor bacteria. Their two largest systems are the FoodSafe Slot Drain and Trench Drain, but they also offer Area and Hub Drains for tighter spaces. All of the systems are also heavy-duty and forklift-rated, to ensure that they won't bend, bow, or break under the weight of equipment.

The FoodSafe Trench Drain features a wide channel for large flow rates and a thick, stainless steel grate. The FoodSafe Slot Drain is similar, as both are subsurface systems, but the Slot Drain has a slimmer channel that doesn't need any grate covering. Both systems are compatible with clean-in-place technology for easier, automated cleaning.

Taking The Time to Plan a Facility Correctly

Seafood processing requires great care to prevent harmful pathogens from forming.

Taking the extra time to carefully plan your facility's layout and design to ensure a safe, hygienic design is vital for the safety of consumers–and your success. This article only covers some of the essential components, but many more go into a safe and sanitary facility. Starting with the drainage can provide you with a solid foundation to build on top of and create an efficient shellfish processing plant.

Contact FoodSafe Drains today to learn more about their drainage options and discover which is best for shellfish processing plants.