Restaurants and commercial kitchens have a lot going on, from food deliveries to serving customers.

They require managers and their staff to pay close attention to all the details, especially concerning food safety and sanitation. Restaurants and kitchens must dedicate the time to ensuring they meet the required food sanitation standards.

Following food sanitation standards and guidelines will help prevent the spread of foodborne illness-causing pathogens.

What is Food Sanitation? What Are Food Sanitation Rules?

Food sanitation, which falls under food safety, refers to operations within food establishments that aim to create a more conducive environment for food preparation. It aims to eliminate food safety hazards, particularly sources of contamination, to ensure food is safe for consumers and free from foodborne illness.

Food sanitation involves specific standards, or food sanitation rules, set by state and federal government agencies that help maintain the facility's cleanliness, including food contact surfaces, equipment, and other points within the food supply chain.

The manager is responsible for knowing the food sanitation rules and ensuring that all employees have the proper training to execute them appropriately.

Why Are Food Sanitation Rules Important?

Food sanitation goes hand-in-hand with food safety. Without sanitation, there is still a significant risk of foodborne illness outbreaks occurring. In short, food sanitation addresses:

Food Safety Issues

Food sanitation practices help minimize the risk of cross-contamination since properly sanitizing tools and equipment can significantly reduce the presence of harmful pathogens. Proper sanitation will also help minimize the risk of cross-contact contamination between allergenic and non-allergenic foods.

Better Equipment Maintenance

Regularly sanitizing tools and equipment allows employees to inspect everything and determine if anything needs maintenance work, which helps to ensure equipment is always functioning as intended. Workers can also determine if there are any hazards within the kitchen, like chipped walls or floors, bent food-contact surfaces, or broken glass, which can harbor pathogens or contaminate food products.

Better Safety Conditions

By better maintaining the equipment and ensuring the facility is clean, you help to ensure a safer work environment, which can significantly reduce the risk of accidents and allow workers to be more efficient. Workers are also less likely to get sick or spread foodborne pathogens when food sanitation rules are followed, like regular hand washing.

Improves Business Reputation

Food sanitation rules aren't limited to kitchens; they also apply to the food service areas. When you pay more attention to the sanitation of these areas, customers will notice and feel safer and more confident, knowing you are taking their health and safety seriously.

Food Sanitation Rules to Follow

Restaurant managers need to take steps to ensure the safety and cleanliness of their business. This includes following various food safety rules, including rules regarding sanitation. The food sanitation rules require managers to implement different food safety programs to address the safety and sanitation in different areas of their facility and the production process. Some safety programs and rules include:

1. Personal Hygiene

Personal hygiene is vital to food safety and sanitation. Poor hygiene is one of the leading causes of foodborne illness; it is also one of the easiest problems to fix.

Wash Hands Properly

If employees aren't washing their hands properly, they risk spreading germs and bacteria. Proper hand washing means washing your hands with soap and water for 20 seconds. Employees should wash their hands before dealing with food, switching tasks, touching unsanitized surfaces, sneezing, coughing, and using the bathroom.

Wear Clean Uniforms

Another thing addressed by food sanitation rules is how employees should dress. Food sanitation rules require the manager to ensure employees wear clean uniforms, hair and beard restraints, and that they do not wear jewelry beyond plain wedding bands while working.

Dirty uniforms should be stored away from the food prep areas. Employees should also wear disposable gloves that should be changed when working with different foods or after touching non-food-related items.

Employee Illness

Another requirement of food sanitation rules is reporting illness. Employees should report illness to their manager, especially if they come into contact with foodborne pathogens like Norovirus, Shigella, Salmonella, etc., and they need to stay home to prevent spreading illness. If illness presents while working, managers should take the proper precautions to ensure that they clean and sanitize all surfaces in order to prevent an outbreak.

2. Food Handling

The manager is responsible for knowing the food sanitation rules regarding food handling. Proper food handling starts the moment food shipments arrive, and the rules include:

Inspect Every Food Shipment

All food shipments require careful inspection. Employees should ensure everything arrives at the appropriate temperatures, free from pests and defects. Foods that do not meet necessary standards should be rejected.

Prevent Cross-Contamination

There are many ways cross-contamination can occur. To prevent this:

- Store raw, uncooked, and Potentially Hazardous Foods (PHFs) away from other foods.

- Use separate cutting boards and tools for different products. A color-coded system can help to prevent confusion.

- Sanitize food-contact surfaces and tools after each use.

- Wash hands after handling food products, particularly PFHs.

Cook Foods to Appropriate Temperatures

The food sanitation rules require employees to ensure food is cooked appropriately to ensure it is safe and any potential pathogens are destroyed.

3. Holding and Storage

The manager is responsible for knowing the food sanitation rules; this includes the supervision of the handling and storage of food products.

Food Holding

When restaurants prepare ready-to-eat food, whether hot or cold, they must be stored at an appropriate, consistent temperature to avoid the growth of harmful pathogens.

Cool Foods Safely

Cooling foods to later reheat them also requires care. Safely cooling foods for reheating is a two-step process: cooling them down from 135ºF to 70ºF within two hours and then to 41ºF in four hours.

Proper Food Storage

To follow food sanitation rules, store foods in the "first in, first out" method, with newer foods in the back and older foods in the front to get used first. Time-temperature control for safety (TCS) foods, like meat, poultry, dairy products, seafood, and eggs, should go on cold storage shelves in a particular order to prevent liquids from dripping onto the food below and causing contamination.

Store foods in the following order:

- Ready-to-eat products

- Seafood

- Whole-cut beef and pork products

- Ground meats and fish products

- Whole and ground poultry

4. Cleaning and Sanitizing

A significant part of food sanitation and safety is proper cleaning. The manager is responsible for knowing the food sanitation standards, such as:

Proper Cleaning and Sanitization of Food Contact Surfaces

Cleaning and sanitation are necessary to eliminate contaminants from food contact surfaces like prep tables, tools, and other equipment. The proper process includes:

- Remove crumbs and food particles from the surface.

- Use a food-safe cleaning solution.

- Rinse with clean water.

- Use a sanitizing agent mixed to the correct concentration.

- Allow the surface to air dry.

Clean and Sanitize Equipment

Cleaning and sanitizing equipment takes longer than food contact surfaces, and the food sanitation rules require someone to refer to the manual for the different equipment to ensure they use the appropriate method.

Dishwashing Protocols

Not everything can go through a dishwasher in a commercial kitchen. Large items, including pots and pans, require manual cleaning in a three-compartment sink, while serving ware can go into a high-temperature dishwasher.

Drainage

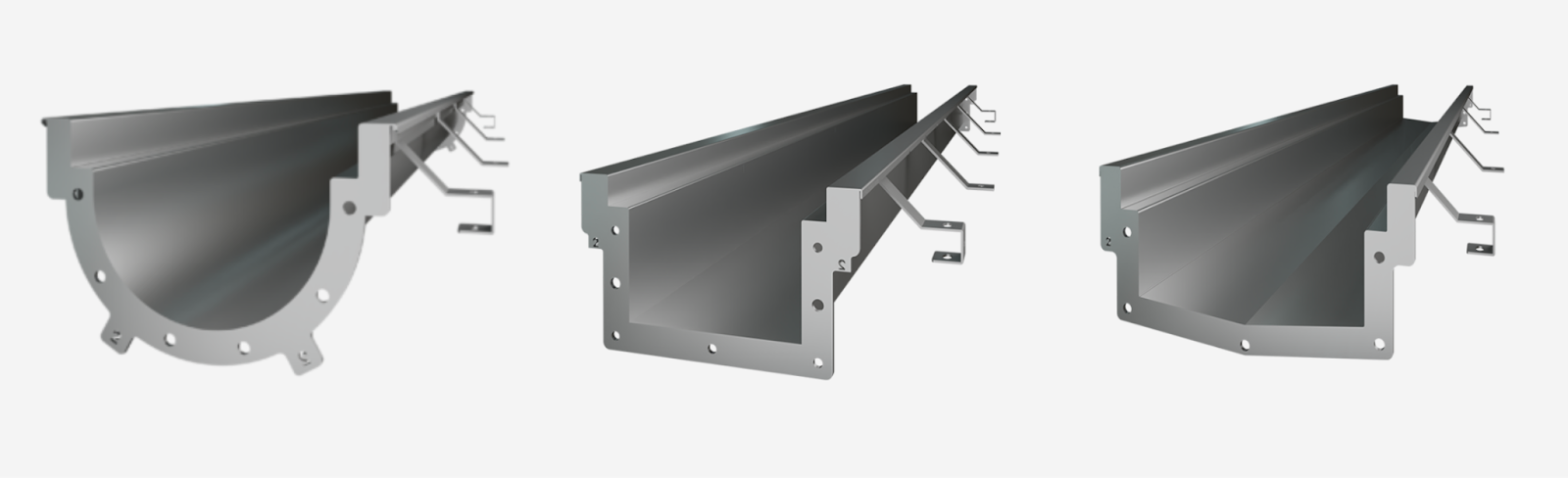

Floor drainage, like the systems offered by FoodSafe Drains, also play an important role in creating a sanitary facility. Options like the grate-free Slot Drain, grated Trench Drain, various hub and area drains, and Floor Sinks all offer sufficient drainage solutions. All FoodSafe Drains systems are NSF certified, with T304 and T316 stainless steel construction and forklift-rated load class abilities. The systems are easy to maintain, safe, and effective.

5. Pest Control

The manager is responsible for knowing the food sanitation requirements for pest control.

Prevent Access to the Facility

Managers must ensure they cut off all access to the facility, including installing door sweeps, sealing cracks and holes, and using air curtains to ensure pests cannot enter the facility.

Prevent Access to Food and Shelter

Employees should take out the trash throughout the day and should ensure that the dumpster remains securely closed to prevent unwanted entry. Inside the facility, ensure crumbs and food debris are cleaned up quickly in the kitchen and the front of the house.

Hire Professionals

If necessary, hire a professional company for further help with pest control. They can help identify issues with the facility and better eliminate the risk of pests.

6. Only Buy from Reputable Sources

The manager is responsible for knowing the food suppliers they are buying from. Only buy from trustworthy suppliers who meet local, state, and federal requirements. You also want to ensure the supplier can provide inspection reports upon request.

7. Training and Monitoring

Standard Operating Procedures (SOP)

An SOP is the written rules or guidelines of a food service business. A written SOP is a way to hold staff members accountable as they outline the rules that employees must follow to ensure food safety.

Training Employees

Managers should invest the time to train staff members on the SOP rules and guidelines. The more effort you put into training members, the better they will understand and implement the rules, which can significantly improve your business's food safety and sanitation standards. Have refresher courses to ensure everyone remains sharp in what is expected.

Monitor the SOP

Monitoring your SOP in action is vital, not only to ensure employees are following it, but to make sure that it is proving effective. Check the temperatures in storage areas, ensure all guidelines are followed, and address any issues you find. If necessary, make changes to your SOP and educate your staff on the changes you make so they are aware.

With Food Safety Comes Food Sanitation Rules

Having a complete food safety plan means also addressing food sanitation. It is vital to be thorough when addressing food sanitation, as it plays a vital role in eliminating and preventing foodborne pathogens. Food sanitation rules provide clear guidelines for every aspect of the food chain within a restaurant, from accepting food deliveries to employee training.

One step to take is installing a food-safe drainage system. Contact FoodSafe Drains today to learn more about their drainage systems and how they can work in your facility!