More and more frequently, people are reading ingredient labels and noticing certain ingredients.

Palm oil, for example, has been around for a long time and is present in many products. It is also a product that has people divided on whether it is good or not for many reasons.

Here is what you should know about palm oil and palm oil processing factory design.

What is Palm Oil?

Palm oil (Elaeis guineensis) is a vegetable oil that comes from the fruit of oil palm trees. The fruit can produce two types of oil:

- Crude Palm Oil: derived from squeezing the fleshy fruit

- Palm Kernel Oil: derived from crushing the fruit's stone

While native to Africa, oil palm trees were introduced to Southeast Asia over 100 years ago as ornamental plants, but countries eventually began making oil. Since then, Indonesia and Malaysia have become significant sources of palm oil production, and they produce around 85% of the global supply. 42 other countries also produce palm oil.

Palm oil is one of the most common oils used for everything from pizza to lipstick. You can also find it used as animal feed and even biofuel in some parts of the world. While widely used in products, palm oil is controversial because it has been a major driver of deforestation, which has increased greenhouse gas production and habitat loss for various species. There are also concerns about worker exploitation and child labor.

These are all serious issues that must be addressed, which has led to a push for sustainability in palm oil production.

Palm Oil and Sustainability

The Round Table on Sustainable Palm Oil (RSPO) was formed in 2004 in response to the increasing concerns about the impact of palm oil on society and the environment. Over 4,000 organizations are members of the RSPO, including well-known ones like the WWF and Unilever. Together, these organizations have created a standard for sustainable oil production called the RSPO Principles and Criteria.

The standard addresses everything from preventing deforestation to worker wages and labor standards. More changes can be made as more organizations join RSPO, to help make sustainable palm oil the standard.

Importance of the Right Plant Design

Producing sustainable palm oil is vital, but you need the right palm oil processing factory design to produce it. The right design and lay will allow you to increase your production capacity while lowering operating costs. It will help to ensure that everything runs safely and efficiently.

Elements of Palm Oil Processing Factory Design

Like all plants and factories, palm oil processing plants have specific elements needed for facility design.

Location

Choosing the right location is essential. To cut operational costs, you should build your plant in a well-situated location; the less distance raw materials have to travel, the more you will save. Your chosen location should also take accessibility into account for workers, delivery drivers, and emergency services. You must also consider the proximity and availability of energy resources, like electricity and water.

A Smart Layout

The layout is also vital. For your plant to run smoothly, your palm oil facility layout should follow the production process. It should go from receiving the palm fruit through the various production steps to ending with the final product shipment and distribution. This will reduce production time since everything is in order, and employees don't have to go back and forth for different steps. It will also make the facility safer and reduce the possibility of injury since employees will not have to move far for the next step.

The layout should also account for the equipment size; everything should fit comfortably while allowing for easy movement and space for maintenance work.

Processing Equipment

No palm oil processing factory design is complete without the processing equipment. You should invest in high-quality pieces with features like clean-in-place and that are easy to work with and maintain. Examples of equipment you need include a sterilizing system, threshing system, pressing system, and bulk oil storage system. Your equipment size should be sufficient to support anticipated production amounts.

Other Facility Features

Besides the processing equipment, there are other features to consider in your plant design process. Palm oil processing plants also require sufficient lighting, good quality ventilation, and well-controlled temperature and humidity levels, among other things. You should invest in the best possible equipment, including HVAC and humidifier or dehumidification systems, to meet these needs.

Drainage

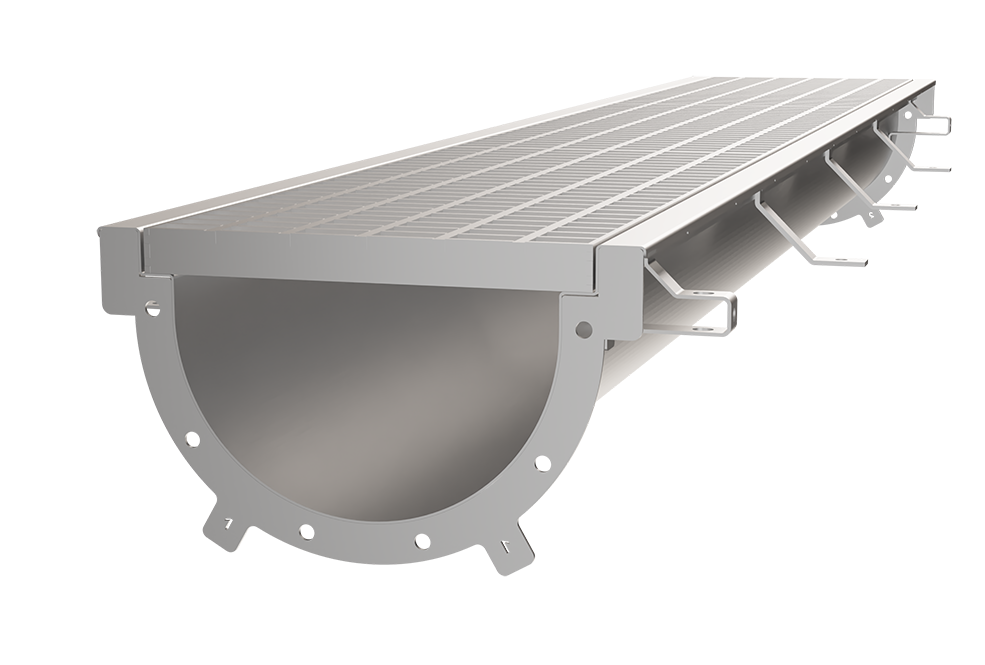

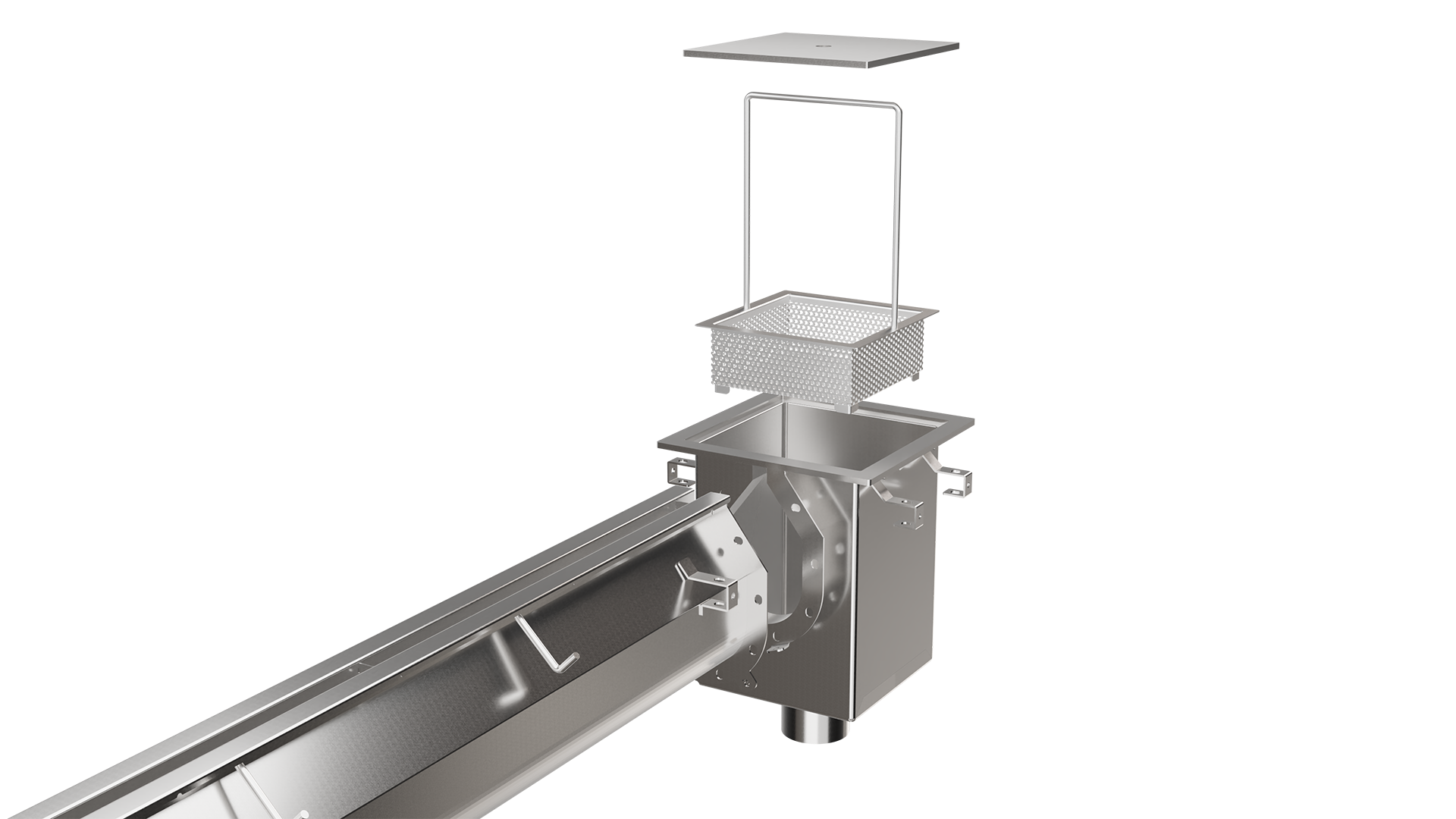

Drainage is another vital element of a palm oil factory design. FoodSafe Drains offers systems designed for the food industry, which all feature an NSF-certified design and T304 and T316 stainless steel. They are also heavy-duty, forklift-rated, perfect for factory settings. Drainage options include:

The FoodSafe Slot Drain and Trench Drain

Both systems are subsurface drains with a continuous channel that helps move waste to a designated outlet. The FoodSafe Slot Drain has a small channel opening with a grate-free design that can handle flow rates up to 27 GPM. The FoodSafe Trench Drain can handle larger flow rates with a wider, grated channel. Both are compatible with clean-in-place technology for easy cleaning and maintenance.

Area and Hub Drains and Floor Sinks

For smaller spaces, the area and hub systems can quickly remove standing water. They are equipped with a Tamper-Proof Magnetic Strainer that helps catch larger particles to prevent them from clogging the system. The strainer is only accessible to authorized personnel who have the key, ensuring there can be no tampering.

The FoodSafe Floor Sink is a modern take on the traditional grated point drain. It is designed for more significant flow rates and particulate removal. The Floor Sink has the same Tamper-Proof Strainer technology.

The FoodSafe Catch Basin

The FoodSafe Catch Basin attaches to the Slot Drain and Trench Drain Systems, to catch small objects and particles and prevent them from going through the drain. The Tamper-Proof Magnetic Strainer is covered by a durable pan lid, to provide further protection to the drain and employees.

Producing Palm Oil the Right Way

Palm oil is one of the most widely used vegetable oils globally. While there is still much controversy, the RSPO is working hard to change that, by showing that sustainable palm oil production is possible. It isn't just about harvesting the fruit right–you also need to produce it right, which requires the right palm oil processing factory design.

This article only touches on the surfaces of what goes into a factory's design; it is essential to take the time to do your research and set it up right so you can help be a part of sustainable palm oil production.

Contact FoodSafe Drains today to learn more about their drainage options and discover the best option for palm oil factories.