The IDFA (International Dairy Foods Association) reports that dairy consumption reached a record high in 2021. The data showed that the per capita consumption of dairy products increased by 12.4 pounds per person compared to 2020.

Growing dairy consumption requires new dairy processing plants to be built to help meet growing dairy demands. Before starting a dairy plant, you should take the time to understand the importance of the efficient design and layout of a plant and some of the critical elements you need to include.

Why Does the Design and Layout of Dairy Processing Plants Matter?

Dairy products include everything from milk to ice cream and butter, which are some of the most perishable commodities. Without the proper processing and appropriate temperatures, dairy has a short shelf life, which makes time of the essence when it comes to processing. The right plant design and layout will ensure no time is wasted as the product moves through the processing line. It will also help maintain a hygienic facility and prevent contamination, which could cause serious harm to consumers.

What Goes into the Design of Dairy Processing Plants?

A dairy processing plant's design and layout requires efficiency and cleanliness. Specific factors to consider for the design of a dairy plan include:

Location and Site Selection

Before you can begin designing a dairy processing plant's interior, you must choose the right site and location. The location will refer to whether your plant is in the city, the suburbs, or somewhere in the country, further from the city. What location you choose for your plant site typically depends on what you're manufacturing. While any of the previously mentioned locations can work for dairy plants, you want to choose one that offers the lowest cost for producing and distributing products. Some other factors to consider for location selection include:

- Adequate space to build your plant and any other necessary buildings, and roads to allow for potential expansion in the future

- Proximity to raw materials and emergency services

- Availability of workers

- Adequacy of available transportation facilities

The site is the specific area where you choose to build your plant's facilities. It is vital to take your time when considering your site selection. Some things to consider regarding site selection include:

- Do you need a site that has a slope or is level?

- Accessibility of the site?

- Has the land suffered any contamination, and what is the underlying geology of the site?

- How are the water levels and drainage?

- Access to utilities?

- Security?

These are just a few factors to consider when considering different potential plant sites and locations. Take the time to consider every factor carefully for the best choice possible.

Layout and Flow of Plant

The ideal layout and flow would follow the dairy processing steps, from the reception of the raw dairy to packaging and distribution. Having the facility set up efficiently will help to ensure that the facility runs in a smooth, organized fashion without the risk of contamination. It will also ensure quicker processing and less product spoilage risk.

Another aspect of the layout to consider is ensuring sufficient space between the various pieces of equipment to allow for easy movement and any necessary maintenance work.

Equipment

The right equipment is essential for running a dairy processing plant. You want to ensure that you are selecting high-quality pieces that will last, are easy to maintain, and preferably have features like clean-in-place capabilities to ensure thorough cleaning and sanitation. Dairy processing equipment includes milk storage tanks, separators, blending or mix tanks, pasteurization machines, homogenizers, and more.

Flooring

Flooring is another critical part of dairy processing plant design. A dairy plant should use different flooring throughout the facility based on the different needs of each area. All flooring must be waterproof, durable, and long-lasting. You also need a material that is easy to clean, slip-resistant, temperature-resistant, and cost-effective, among other features.

The ideal flooring base is a concrete slab strong enough to support heavy equipment. The slab should have a waterproof, corrosion-resistant membrane coating.

Drainage

Drainage is one of the essential elements in dairy processing plant design. You need an efficient, hygienic system capable of handling large amounts of liquid waste from various sources. Systems should also vary depending on the needs of a given section within the plant.

FoodSafe Drains makes safe, hygienic systems that are perfect for any part of a dairy processing plant.

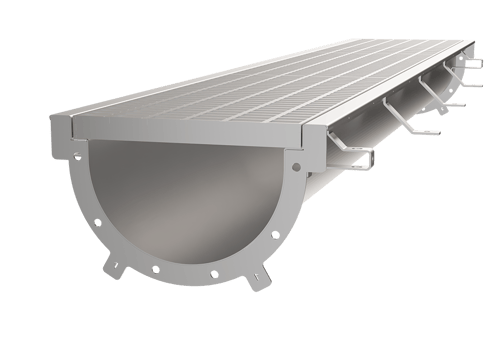

The FoodSafe Slot and Trench Drains

The two effective offerings from FoodSafe Drains are their Slot Drain and Trench Drain systems. Both are subsurface systems with an NSF/ANSI/3-A certified T304 or T316 stainless steel design. They are heavy-duty systems that are forklift-rated and can handle significant flow rates, with the Slot Drain offering rates up to 27 GPM, while the Trench Drain can handle more.

The FoodSafe Trench Drain has a wider drain that is protected by a grate, while the FoodSafe Slot Drain's thinner channel eliminates the need for any covering, for a less noticeable system. Both are easy to clean and compatible with clean-in-place technology and the FoodSafe Catch Basin to help catch debris before it enters the channel.

The FoodSafe Trench Drain has a wider drain that is protected by a grate, while the FoodSafe Slot Drain's thinner channel eliminates the need for any covering, for a less noticeable system. Both are easy to clean and compatible with clean-in-place technology and the FoodSafe Catch Basin to help catch debris before it enters the channel.

FoodSafe Hub and Area Drains

The FoodSafe Area and Hub Drains are other great options for tighter spaces. They feature the same NSF-certified, stainless steel design with a forklift-rated grate cover. The smaller area and hub drains and the larger FoodSafe Floor Sink can easily handle larger flow rates and particulates.

The Right Design for Dairy Processing Plants

Dairy is a common component in food and beverage products. The processing plants that dairy products go through require a particular specific setup to ensure the safety of the various products produced. This article covers only a few aspects of a dairy processing plant design, but they are some of the most vital to ensuring an efficient and hygienic facility. As you design your dairy plant, plan out every detail carefully, from the location down to the drains on the floor.

Contact FoodSafe Drains today to learn more about their products and how they can work in a dairy processing plant!

Small.png?width=400&height=400&name=FSADR512M-84%20(Exploded)Small.png)