No alcohol and low-alcohol (also called non-alcoholic) beer is a fast growing and dynamic segment of the beer market.

As a younger generation of consumers look for healthier lifestyle choices, consumption of non-alcoholic beer has increased significantly over the past few years.

Industry publications report that the non-alcoholic beer market reached a valuation of $21.94 billion in 2024. The market is expected to expand over the coming decade with a predicted 10% growth rate through 2035. This trend has given rise to specialized startups in the craft brewing industry as brands have appeared whose entire product line is non-alcoholic beer.

Savvy craft brewers know that there is very little difference between brewing a good beer and brewing a good non-alcoholic beer. These brewers are well positioned to take advantage of this new and growing market. They possess the equipment, knowledge, and resources to produce quality non-alcoholic offerings and introduce their brand to a new type of beer drinker.

FoodSafe Drains has supplied drainage to over 100 breweries across North America over the past decade. We look forward to supplying sanitary drainage for both regular and non-alcoholic brewers as the market evolves through the decade to come.

“Working with the Slot Drain Systems (a division of Global Drain Technologies) team has been outstanding. You guys put a lot of attention into not only the product but also the service and the team and the response time. I can call you guys midday and have a quote by the end of the day. There’s nothing out there that compares.”

-Shawn MacDonald, Brewery Installation & Maintenance Services.

In this blog we’ll see how proper drainage is foundational to brewing in today’s ultra competitive non-alcoholic beer market.

Non-Alcoholic Beer, Different Product, Same Process

Brewing a non-alcoholic beer (in North America) means producing a final product with an ABV of 0.5% or less. While the outcome of this endeavor may be different from brewing regular beer many of the processes remain the same.

Brewers who want to produce a quality non-alcoholic beverage still need to secure a pure water source and a flavorful malt. They need brew kettles to produce wort and they need a sterile environment to begin fermentation. After this, the process changes slightly. To create a low alcohol beer the wort is usually prepared at a lower specific gravity and specialized yeasts are used that produce low-alcohol fermentations. For zero-alcohol beers, a beer is brewed and then proprietary processes are used to remove the alcohol from the beer after brewing.

Because so much of the processes and equipment are the same, the same best practices that apply to regular brewing apply to brewing a non-alcoholic beer. However, brewers should know that the non-alcoholic market is an ultra-competitive space focused on unique and flavorful offerings. Gone are the days of your grandpa’s generic non-alcoholic beer. Today’s beers compete on flavor with their full alcohol cousins.

Sanitation and its Effects on Flavor

Every good brewer knows that brewing a quality and flavorful beer is all about sanitation. We at FoodSafe Drains have seen time and again the same situation where talented brewers have spent a great deal of time and energy picking out hygienic equipment while overlooking hygienic drainage.

Drains are equipment and just like every other piece of brewing hardware, they should be constructed with hygienic design principles in mind. It’s easy to pick out the signs of unhygienic brewery drainage. Everyone who has toured through breweries with dirty drains knows the telltale sour smell this issue causes. This smell is not only unpleasant for workers it is an indication of larger problems.

Many of the positive bacterial screens in food and beverage production environments come from the drains. In industries like meatpacking this increases the risk of contamination of the production line and associated foodborne illnesses. In a brewery harmful bacteria can contaminate a batch of beer affecting the flavor and leading to an inferior product.

“I’ve been in places where they don’t have good solutions for removing water or removing grain from the area. It just creates all sorts of problems. One you could infect your beer with bacteria if you’re not clean. Two it’s just a pain to work in. There’s water there’s chemicals there’s all sorts of stuff on the floor the faster you get that into a drain the better off you are the better off your product is.”

-Colin Koop, President Devil May Care Brewing

Before you queue a new non-alcoholic brew, take a few minutes to do a complete inventory of your sanitation and cleaning processes. Is everything at the elite level, or is there room for improvement? Like Olympic running, brewing is such a refined process in the 21st century that top brew masters compete on fractional improvements to best their opponents. Especially in the non-alcoholic beer market space.

Choosing proper drainage for your brewery is one of the most overlooked yet most effective ways to improve the overall quality of your final product and beat out the competition for the hard earned cash of your customers.

The High Cost of Bad Drainage in Breweries

Flooding and Water disruption: Improperly sloped floors combined with insufficient flow rates can cause flooding leading to production disruptions, equipment damage, and costly repairs.

Equipment Corrosion: Excessive moisture can lead to a reduced lifespan of expensive equipment and high capital costs.

Worker Safety: Wet floors can cause staff to slip and fall. This can lead to sick leave, lost productivity and even worker’s compensation claims.

Fines and Shutdowns: A lack of sanitation caused by insufficient, dirty, or clogged drains can lead to non-compliance penalties and even brewery closures.

How to Choose Effective Drainage

With the large quantity of wastewater being produced in your brewery selecting proper drainage is one of the most important choices you can make. Look for these features:

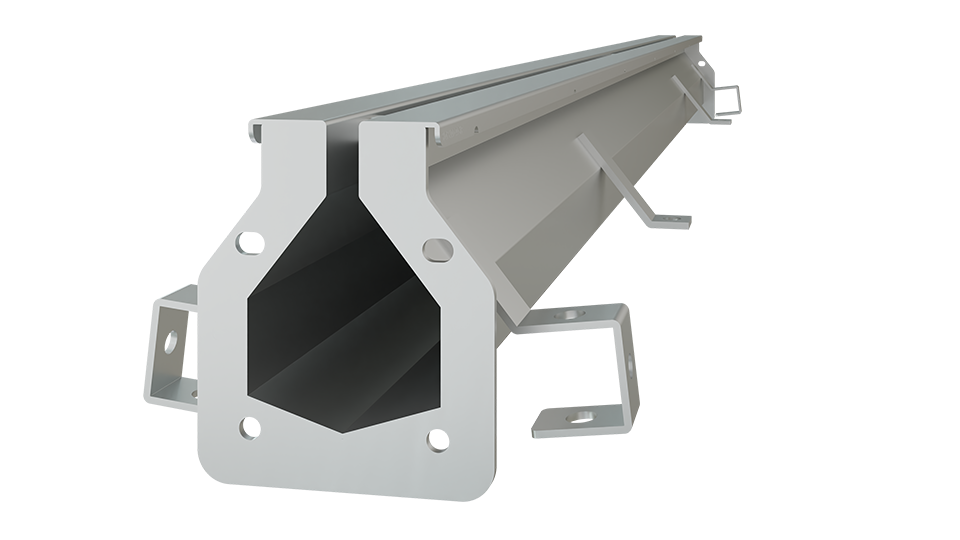

Ease of maintenance: Drains should be easy to clean to a microbiological level. This means selecting drains that are manufactured using hygienic design principles and made from food grade materials such as stainless steel.

Load bearing: Drains need to be designed to withstand repeated heavy loads like forklifts without cracking or bending.

High Flow Rates: Drains should offer flow rates that prevent wastewater from pooling on the floor.

Corrosion-resistant and built to last: Choose drains made from stainless steel. Stainless steel will not rust due to its chromium content which forms a protective outer layer that resists rust and corrosion.

Recommended For Breweries