Hub drains are not just a commodity. Their role in indirect drainage in the food and beverage processing industry is crucial to plant safety. Ensuring that all your drains, including hub drains, are manufactured using hygienic design practices can help to prevent contamination of product and costly plant shutdowns.

“I have toured food plants where floor drains were being used as hub drains,” says Chad Kaatz VP of Engineering and Product Management at Global Drain Technologies. “This unapproved drainage setup led to plant employees jerry-rigging an indirect drainage system. The setup was difficult to clean, creating unsanitary conditions that could be a vector for contamination,” says Kaatz.

In this blog we will explore the world of hub drains, what they are, their main uses and why it is important to select a quality drainage manufacturer that understands the needs of the food and beverage processing industry when choosing a hub drain.

What is a Hub Drain?

Hub drains are specialized drains made to provide drainage for equipment whose drainage outlets require an air gap before draining into the main wastewater system. They are installed with a rim that protrudes above the level of the surrounding surface.

The bottom of a hub drain corresponds to the size of the plumbing main (often 4” or 6”) while the top is wider (often 6”or 8” but it can be larger) and acts as a funnel to accept liquids from one or more pieces of equipment. The top and the bottom of a hub drain are connected via a reducer coupling giving them a distinctive bell shaped center.

What is a Floor Drain?

Floor drains (also called area drains) are multipurpose drains that are installed flush with the floor to drain a specific area of 400 square feet or less. Floor drains / area drains are point drains designed for either indoor or outdoor use. They are generally constructed with a removable cover and strainer basket to protect, and allow access to, underground plumbing. Area drains are typically round or square in shape and can vary in size from a few inches to a few feet in diameter.

Hub Drain vs. Floor Drain Comparison

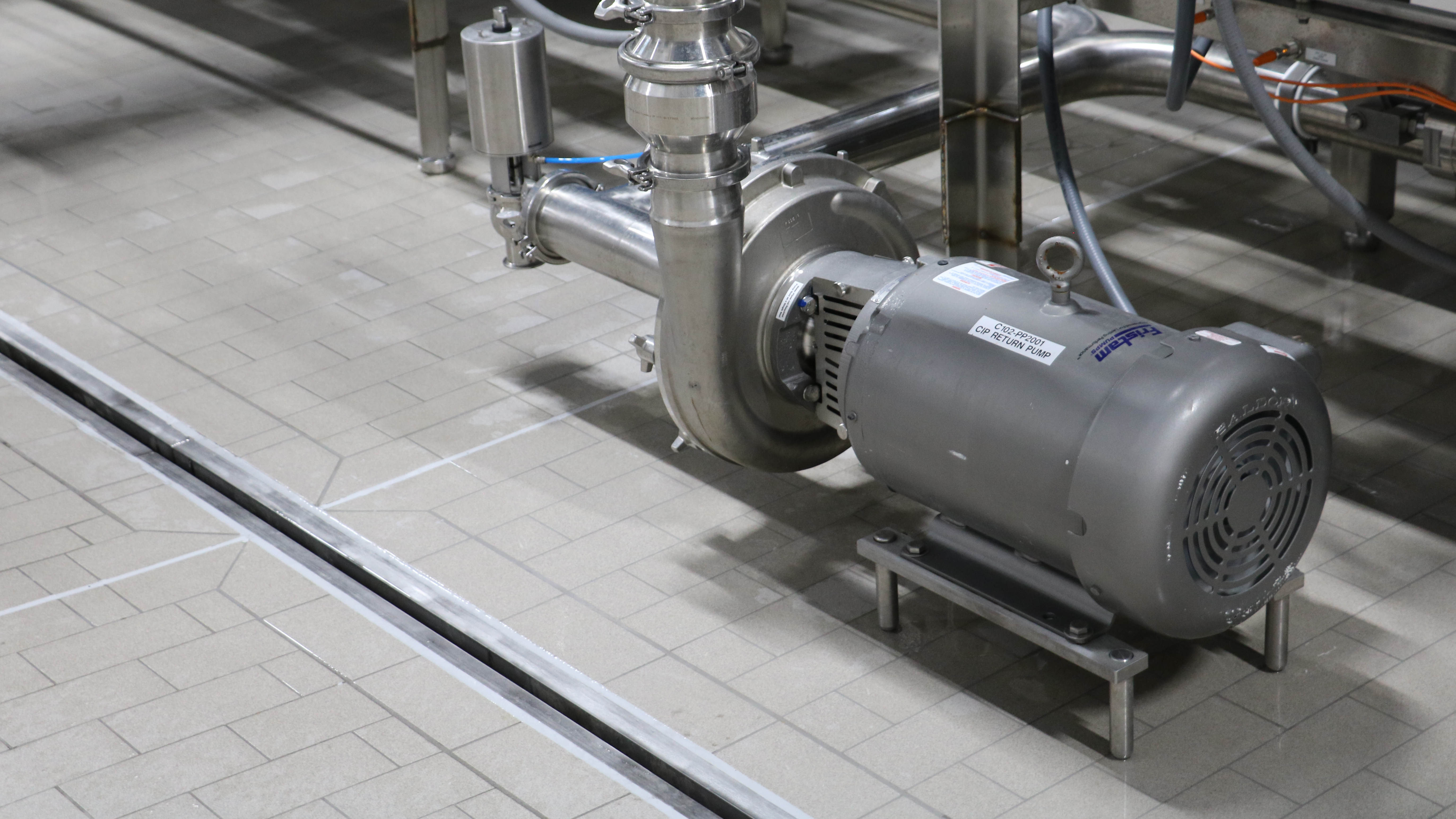

Left: Floor Drain with cover removed being used as a hub drain. Erosion and buildup of debris is visible leading to unsanitary conditions.

Right: Hub drain with funnel being used as a hub drain. Clean installation with a sanitary outcome.

Hub drains and floor drains are similar because they are both point drains that connect directly to the main plumbing system. But hub drains and floor drains are different because hub drains are made to accept runoff from a specific piece (or pieces) of equipment while floor drains are made to drain a specific area of the floor. This functionality is visible in their design, with floor drains fitting flush to the floor and hub drains having a rim that extends beyond the level of the floor.

Floor drains can be used as hub drains but this is not ideal. When a floor drain is used as a hub drain the cover is often removed to allow it to accept greater volumes of liquid without overflowing. This is not a floor drain’s intended purpose and can lead to sanitary issues. It is always better to use a hub drain to drain fixed equipment that requires an air gap.

The Importance of Indirect Drainage and Air Gaps.

Hub drains provide indirect drainage with an air gap between processing equipment and main drain lines. An air gap is the physical separation between the outlet of the equipment's drainpipe and the rim of the hub drain. An air gap ensures that should the main drain line backup it will not result in cross contamination of equipment or of processed food or beverage products. This is a required health and safety feature for certain pieces of equipment.

The air gap also enables simple visual monitoring of equipment drainage. Staff can easily see if a piece of equipment is draining or not just by looking at it. The air gap also facilitates cleaning and maintenance. Such accessibility is critical in facilities with high hygiene standards, such as meat processing plants, commercial kitchens, and breweries.

When are Hub Drains Used?

Hub Drains are used to drain equipment that should not be connected directly to underground plumbing such as:

- Walk-in Coolers or Freezers

- Ice Machines

- Steam Kettles

- Commercial ovens and steamers.

Refrigeration units like coolers or freezers are key to the safe storage and handling of products like meat and dairy. If a condensation line on a refrigeration system backs up it can result in a system shutdown and the risk of spoiled product. Hub drains provide an air gap rather than a direct connection to condensation lines. This acts as a failsafe allowing the condensation to drain onto the floor if the hub drain should become blocked. This will alert staff to the blockage and protect the refrigeration equipment from an unscheduled shutdown.

Equipment like steam kettles and commercial ovens can be prone to the formation of vacuums in their drain lines. Using a hub drain provides a failsafe in the form of an air gap. This gap allows for air to flow back into the drainage system preventing the formation of vacuums in the lines. Air gaps prevent wastewater backflow and contamination of processing equipment.

Hygienic Funnels and Strainer Baskets

Because hub drains are so basic it can be easy to overlook hygienic considerations when having them installed. Many food facilities add accessories like funnels and strainer baskets during installation to customize their hub drains. In this situation these items are often manufactured and installed onsite. While there is no problem with doing this, facility managers should ensure that hygienic welding practices are followed in the manufacture and installation of these items.

“I’ve toured food production facilities where the funnels on the hub drains were not manufactured or installed using hygienic design principles," says Chad Kaatz VP of Engineering and Product Management at Global Drain Technologies. “Quite often the funnel portion of the hub drain will be welded onto an existing drain and you find that only the exterior circumference is fully welded while the interior seam is exposed. This leads to an exposed niche where bacteria can take root," say Kaatz.

A weld that is only completed on one side of the hub drain funnel can lead to a seam that creates a harbor point for bacteria. Over time this can become a hot spot for contamination in a food processing facility. Ensuring that all your drains, including hub drains, are manufactured using hygienic welding practices can help to prevent contamination of product and costly plant shutdowns.

The FoodSafe Drains Choice

For guidance on selecting between hub drains and floor drains, please reach out to our sales team. Their expertise will ensure you receive tailored recommendations for your specific project needs.

FoodSafe Drains offers a variety of drainage solutions prioritizing food safety and hygiene. Constructed from Type 304L or Type 316L stainless steel, our NSF-certified, hygienically welded no-niche designs prevent bacterial growth and prioritize food safety. We can supply hub drains, floor drains, slot drains, trench drains and more.

Our sales and engineering staff are ready to tackle your custom project or provide ready-to-ship solutions for your new build or drainage upgrade. Our support and service does not end when we make a sale. Our Alliance Partner network provides a trusted resource of knowledgeable installers across North America who can help take your project to completion on-time and on-budget. Contact us today to start your journey to food safe drainage.