Every food facility manager understands the need for reliable drainage, but not all understand that some systems, such as flood drain grates, come with many problems.

What kinds of problems do drain grates have?

Here is what you need to know about trench or channel drain grates—and why they can be, and usually are, a problem.

WHAT ARE FLOOR DRAIN GRATES?

A floor drain grate is a cover placed over a wider drainage system, like a trench drain. They are designed with small openings that allow liquids to pass through easily while solids and debris get blocked. This helps prevent clogging and other damage that could affect how well the system works.

They are typically made out of plastic and metal, though stainless steel is the most common choice within the food industry because of its sanitary and safety potential.

For instance, without using flood drain grates, employees risk stepping into an open drain and hurting themselves, and the wheels of moving equipment could get stuck in or bounce over the drains, which could send both food and products flying to the ground.

5 PROBLEMS WITH DRAIN GRATES

Although floor drain grates are meant to help—and can be helpful at times—they can actually become more of a hindrance within the food industry. Here’s why:

1. Difficult to Clean

The openings in channel floor drain grates, which allow water to pass through them, are small, which makes cleaning them thoroughly difficult.

Failure to properly clean every crevice of a grate can create a risk of bacteria growth, which can further lead to the spread of harmful pathogens and contamination within a food facility.

It will also mean that your flood drainage does not comply with the strict guidelines for food industry cleanliness, which puts you at risk for violations.

2. They Are Expensive

Maintaining grates is also expensive, not just because of the labor-intensive cleaning and sanitation they require.

In addition, grates aren't the most durable; over time, they begin to wear and tear and break down. How long it takes depends on the materials and the environment where they are installed.

This can happen quickly in food facilities, with constant exposure to acidic ingredients and constant traffic. Regardless, replacing them quickly is vital to preventing more serious issues.

3. Grates Can Cause Injuries

Another problem is that floor drain grates can cause injuries in two different ways.

The first is when workers clean them. Steel grates for drains can weigh anywhere from 40 to 50 pounds, so there is a significant risk of injury during cleaning as workers try to move and handle them. This can lead to worker's compensation claims and other forms of lost revenue.

The second is when workers get injured by tripping over broken grates or grates that don't meet ADA compliance. This is another situation that can result in claims and lost revenue.

4. They Can Trap Bacteria and Odors

Grates made with rough or nonporous materials create a perfect surface for bacteria and contamination to stick to. These surfaces also tend to be more difficult to clean, so food debris and bacteria linger even after cleaning, which allows them to grow and spread, which increases contamination risks and creates foul odors within a facility.

5. They Can Corrode

Channel drain grates cannot withstand exposure to chemicals, acids, or extreme temperatures.

Over time, they will break down, rust, or corrode. The acidic ingredients used to create products, extreme temperatures, and strong cleaning chemicals found in food facilities will contribute to the quicker deterioration of grates

A BETTER SOLUTION

Traditional trench drains have been the primary drainage option in facilities for a long time. While they are effective, the problems that come with these more traditional steel grates for drains aren't worth the hassle.

FoodSafe Drains has solved these issues with their various food-safe drainage systems that feature NSF/ANSI/3-A T304 and use T316 stainless steel.

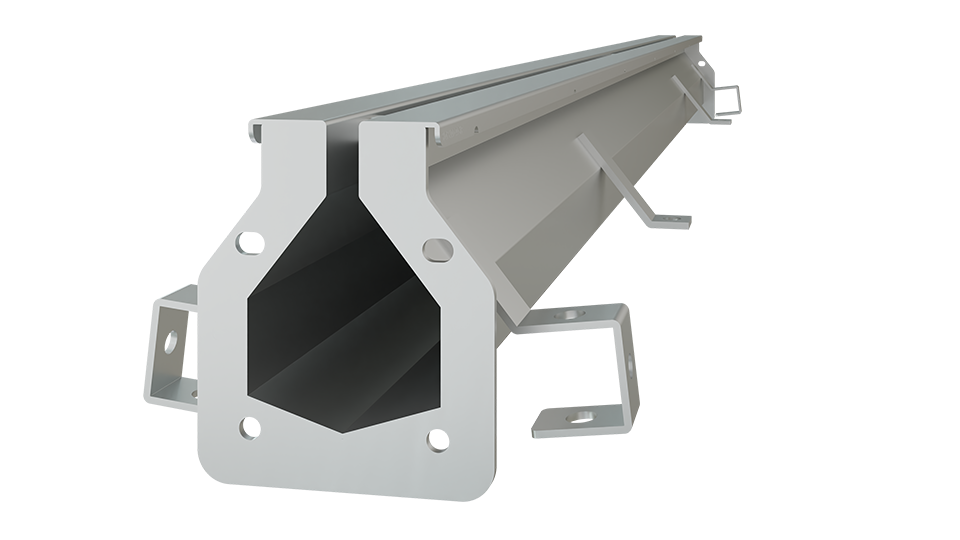

The FoodSafe Trench Drain

The FoodSafe Trench Drain resembles a traditional trench drain, with a wide, grate-covered channel, but the NSF-certified design means it has a smooth interior with radius edges, which means that no sharp corners exist where bacteria can become trapped and grow. It comes in a rounded, flat, or V-Bottom.

The grate is a 1" thick stainless steel with a heavy-duty load-bearing capacity that can support heavy forklifts and pallet jacks without bending or breaking. The smooth, nonporous stainless steel also ensures that it is easier to clean and maintain than traditional grates. It also features a magnetic tamper-proof strainer basket, which catches debris and prevents it from clogging the system, while also allowing authorized personnel to retrieve it easily.

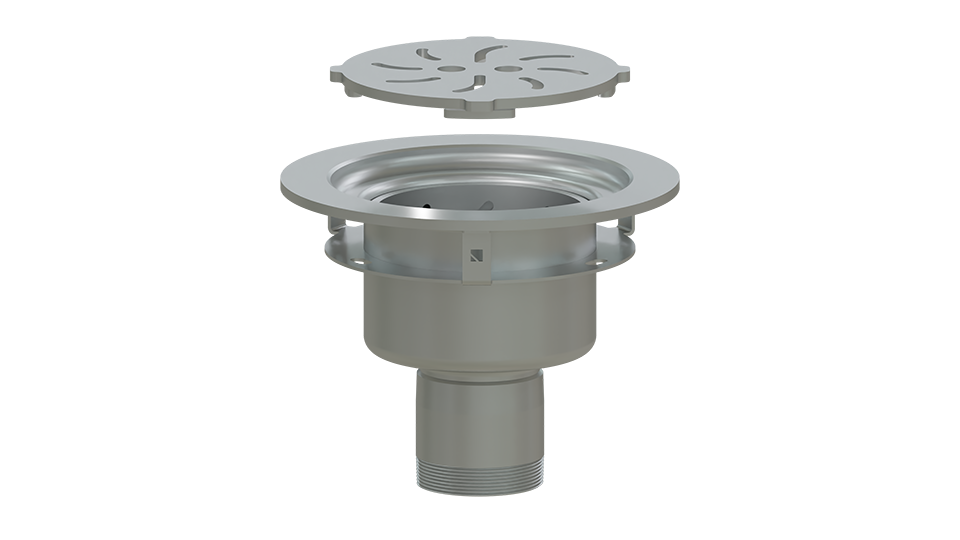

FoodSafe Area and Hub Drains

The FoodSafe Area and Hub Drains feature the same hygienic, stainless steel design, but are best for smaller spaces within food facilities. They have small grates that cover a tamper-proof magnetic strainer basket.

The FoodSafe Floor Sink is a larger-scale hub drain that is capable of efficiently handling large amounts of wastewater and solids. It uses the same tamper-proof strainer basket as the other FoodSafe systems.

Finally, an alternative to grated systems is the FoodSafe Slot Drain. This system features a narrow channel opening which eliminates the need for floor drain grates. All three variations have many of the same features: flow rates up to 27 GPM, a tamper-proof magnetic strainer, clean-in-place technology, and an overall heavy-duty design. The 10,000 and 6,000 PLUS-R Series systems offer Load Class E ratings, while the 6,000 PLUS Series has a Load Class C.

A BETTER ALTERNATIVE TO GRATED SYSTEMS

Drainage is vital for the food industry; drains are meant to maintain clean, sanitary facilities free from bacteria, contamination, and odors. However, this is only possible with the right system, and while trench drains have long been the standard, they don't always stand up to the harsh environment within food facilities.

Drainage is vital for the food industry; drains are meant to maintain clean, sanitary facilities free from bacteria, contamination, and odors. However, this is only possible with the right system, and while trench drains have long been the standard, they don't always stand up to the harsh environment within food facilities.

FoodSafe Drains has addressed this issue by making better trench drains and offering an even better solution that eliminates the need for steel grates for drains: the Slot Drain. Despite its size, it still offers an excellent flow rate to make maintaining sanitary standards even easier.

Contact FoodSafe Drains today—or request a quote—to learn more about our various drainage products and accessories and get a quote for your facility!