Bacteria growth in food processing facilities is a significant concern. Once bacteria begins to form, it spreads quickly, which increases the potential for contamination. If left unmanaged, bacteria can transform into biofilm, an even more serious issue for food processing facilities. Eliminating and preventing bacteria formation, including biofilm, is critical to the safety and sanitation of food facilities. Here are measures you can take to ensure your facility remains bacteria-free:

WHAT IS BIOFILM?

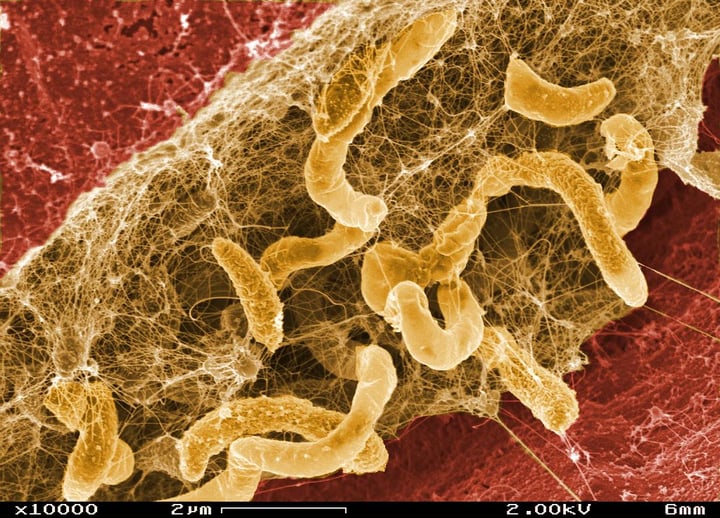

Bacteria can grow in different environments, and it is most common in warm, moist environments where nutrient sources are available. When microorganisms cling to these wet surfaces, they multiply, growing into microcolonies that excrete a slimy, glue-like substance.

DANGERS OF BIOFILM

Biofilm can contain various microorganisms, including spoilage and pathogenic microorganisms. Once biofilms form, sanitizers become ineffective, thus increasing the likelihood of the biofilm surviving and contaminating the food products. The extracellular polymeric substances within biofilm also create a risk of reduced shelf life and disease transmission. Other effects of biofilm include the impairment of heat transfer and corrosion to metal surfaces in the facility.

5 TIPS FOR BIOFILM MANAGEMENT

To avoid the detrimental effects of biofilm, you need to take the correct steps in managing and preventing it from forming. These steps include:

1. THOROUGH CLEANING OF THE FACILITY

One of the most effective ways to manage and prevent biofilm formation is eliminating bacteria before it can begin turning into a biofilm. Food processing facilities use many different chemical cleaning agents, primarily relying on alkali compounds, which act as detergents for fats and proteins. These compounds can work in conjunction with other cleaning agents to eliminate bacteria more effectively. Aside from chemical compounds and agents, superheated water is also effective at dealing with bacteria.

The frequency of cleaning also makes a significant difference in the formation of biofilm. Daily cleaning of food contact surfaces helps to prevent bacteria from colonizing and forming biofilm. Other parts of a food facility, such as storage tanks, pump exteriors, walls, and even ceilings, are cleaned less frequently, increasing the chances of biofilm formation. Taking the time to clean these areas more frequently will further minimize the risk of biofilm formation.

Once biofilm has formed, removing it is a difficult process. Superheated water can remove some of it; however, studies suggest you need to clean with alkali-containing chelators for a prolonged period. The application of sanitizers is also essential to inactivate any microorganisms remaining on the surface after cleaning is completed.

2. USE OF SANITIZERS

Sanitizers also play a significant role in the management and prevention of biofilm formation. Typically, the food industry relies on halogens, peroxygens, acids, and quaternary ammonium compounds for sanitizers. The effectiveness of a chemical sanitizer depends on the presence of soil, water hardness, temperature application, and the ability for physical contact with the microorganisms. The selection of sanitizers should be based on whether or not there is a biofilm present.

3. PROPER EQUIPMENT DESIGN

Having the right equipment within the facility is essential. Equipment should be fabricated using high-quality materials that are approved for food processing facilities. It should feature a design that prevents dirt and debris from accumulating and is easy to clean and maintain.

The design of the equipment is not the only concern. The facility should also have the right layout to ensure smooth operations and, if possible, allow for the installation of a CIP system.

4. SANITARY DRAINAGE INSTALLATION

.png?width=720&name=pasted%20image%200%20(28).png)

There is no overlooking the importance of a drainage system within food processing facilities. Systems like FoodSafe Drains’ Slot Drain help prevent standing water by taking it into a drain channel where it is taken to the appropriate place for disposal. The industrial-strength system features a clean, no-niche design that prevents bacteria from getting trapped. It is also constructed of non-porous, NSF-certified stainless steel. The design eliminates a need for a grate, making inspecting and cleaning the system much easier. FoodSafeDrains 10,000 Series system is also compatible with a CIP system, helping to make it even more sanitary.

5. EARLY DETECTION

A large part of biofilm management is biofilm detection; the quicker you catch bacteria growth, the quicker you can eliminate the issue before it becomes more difficult. The more traditional method of biofilm detection includes swabbing solution, the use of contact plates, and the dipstick technique. Other possible detection techniques include an ATP bioluminescence test. While these tests do not provide quantitative results, they are useful in detecting biofilm formation, which allows you to take the proper steps to remedy the problem.

MANAGE AND PREVENT BIOFILM FORMATION

Biofilm creates many dangers, including increased risk of contamination, the possibility of food spoilage, and more. Bacteria alone is harmful, but the issue becomes much worse when left unmanaged and allowed to colonize. Once biofilm forms, removal becomes difficult, which is why taking steps to manage and prevent biofilm formation is so critical. Taking the proper steps will protect your facility and the food products you produce from contamination and will prevent serious food-borne illnesses.