When we think about food safety modernization, we often focus on stainless steel tables, high-tech sensors, and sterile packaging lines. However, a critical piece of the puzzle lies right beneath our feet. In the United States, the regulatory landscape for food and beverage production has shifted dramatically, placing a newfound emphasis on hygienic drainage as a vital component of a safe and compliant facility. While drainage was once an afterthought in facility design, it is now recognized as essential for managing liquids in environments ranging from vegetable processing to high-risk meat production.

In the United States, the shift from traditional inspections to a more rigorous, proactive regulatory framework has made hygienic drainage a non-negotiable priority. This blog explores how regulations define the role of drainage in food safety compliance.

The FSMA Paradigm Shift: Prevention Over Reaction

The Food Safety Modernization Act (FSMA), enacted in 2011, represents a landmark shift in U.S. law, moving the focus of food safety from reacting to contamination to preventing it entirely. This law grants the FDA expanded authority to implement preventive controls and enhance oversight across the entire food supply chain.

While drains have traditionally been viewed as part of the waste stream and therefore not governed by strict hygienic equipment design standards, this perspective is rapidly changing. The FSMA's requirements are clear:

- Preventive Responsibility: Section 103 states that the owner or operator of a facility must evaluate hazards and implement preventive controls to significantly minimize or prevent their occurrence.

- Pathogen Prevention: In practice, this means eliminating areas where pathogens like Listeria or Salmonella can harbor and grow.

- No Differentiation of Hazards: The wording of the FSMA does not differentiate between types of hazards, putting the onus on the facility to ensure drains are built to prevent pathogen formation.

The reality of contamination is that many drains have listeria and other harmful bacteria lurking out of sight, forming a ticking time bomb of liability. Research by FoodSafe Drains shows that a majority of positive bacterial screens are found specifically in the drainage and floor environment. It is not enough to simply make sure the bacteria stay in the drains, modern producers need to fight contamination at the source.

Decoding the Code of Federal Regulations (CFR)

If the FSMA is the overarching law, the Code of Federal Regulations (CFR), specifically Title 21, contains the detailed rules and regulations enforced by the FDA and USDA. These rules deal directly with how drainage must function within a sanitary facility.

- 21 CFR 117.37 (Sanitary Facilities): This section mandates that plumbing must be adequately sized, designed, and installed to properly convey liquid waste from the plant. It specifically requires “adequate floor drainage” in any area subject to flooding-type cleaning or where operations discharge water on the floor.

- 21 CFR 117.31 (Equipment Construction): While drains are not strictly "food contact surfaces," it is highly plausible that employees will come into contact with both the floor/drainage environment and the production line during a shift. Precautions should therefore be taken to create drains that as closely as possible mimic the hygienic design principles used throughout the rest of the production facility.

- Hygienic Design Principles:

- Be easily cleanable and installed to facilitate maintenance.

- Be made from corrosion-resistant materials.

- Be designed to withstand aggressive cleaning agents and sanitizing procedures.

- Use smoothly bonded seams to minimize bacterial harborage points.

GFSI: The Industry’s "Gold Standard" Audit

Beyond government mandates, many U.S. producers follow the Global Food Safety Initiative (GFSI). This is a private, industry-led organization that oversees universal standards for food safety audits, such as the BRCGS and SQF standards.

GFSI certification allows a manufacturer to immediately demonstrate to customers that they operate a comprehensive food safety program. These standards rely heavily on the Hazard Analysis and Critical Control Point (HACCP) program.

HACCP is a systematic approach to the identification, evaluation, and control of food safety

hazards based on the following seven principles:

- Conduct a hazard analysis.

- Determine the critical control points (CCPs).

- Establish critical limits.

- Establish monitoring procedures.

- Establish corrective actions.

- Establish verification procedures.

- Establish record-keeping and documentation procedures.

FoodSafe Drains through its work with food and beverage producers has identified drains

as a critical control point. By manufacturing and installing hygienic compliant drainage

FoodSafe Drains allows owners and operators to manage this critical control point ensuring

that drains do not become a harborage point for bacteria.

Types of Hygienic Drainage

Underground plumbing like P-traps should be made from stainless steel to prevent corrosion and collapse.

Manufacturing and Installation

To ensure high safety and compliance, FoodSafe Drains designs its systems according to EN 1672 and EN ISO 14159—standards typically reserved for food-contact machinery rather than waste streams. By treating drains as a "critical control point," these standards dictate precise engineering requirements that eliminate bacterial harborages.

Material Integrity: T304 & T316 Stainless Steel

Stainless steel is the industry standard because it is easily cleanable at a microbial level and can withstand the extreme temperature fluctuations and harsh chemicals used in food processing. These grades of stainless are resistant to corrosion and prevent the pitting and rusting that can trap microbes All welded areas undergo chemical passivation to restore the protective oxide layer destroyed during the welding process.

Geometry and Radius Requirements

Standard drains often feature sharp angles that are nearly impossible to clean effectively. Under hygienic standards all internal corners must be rounded. This ensures cleaning tools can reach every surface and prevents organic buildup. To ensure proper drainage channels are engineered with positive slopes. This ensures liquids move toward the outlet rather than pooling and creating odors or stagnant bacterial zones.

Sanitary Joint Construction

Traditional drainage often uses overlapping metal, but hygienic standards prohibit these "lap joints" because they create inaccessible voids. In hygienic design welds are placed on flat surfaces rather than in corners, ensuring the resulting seam is smooth and free of crevices.

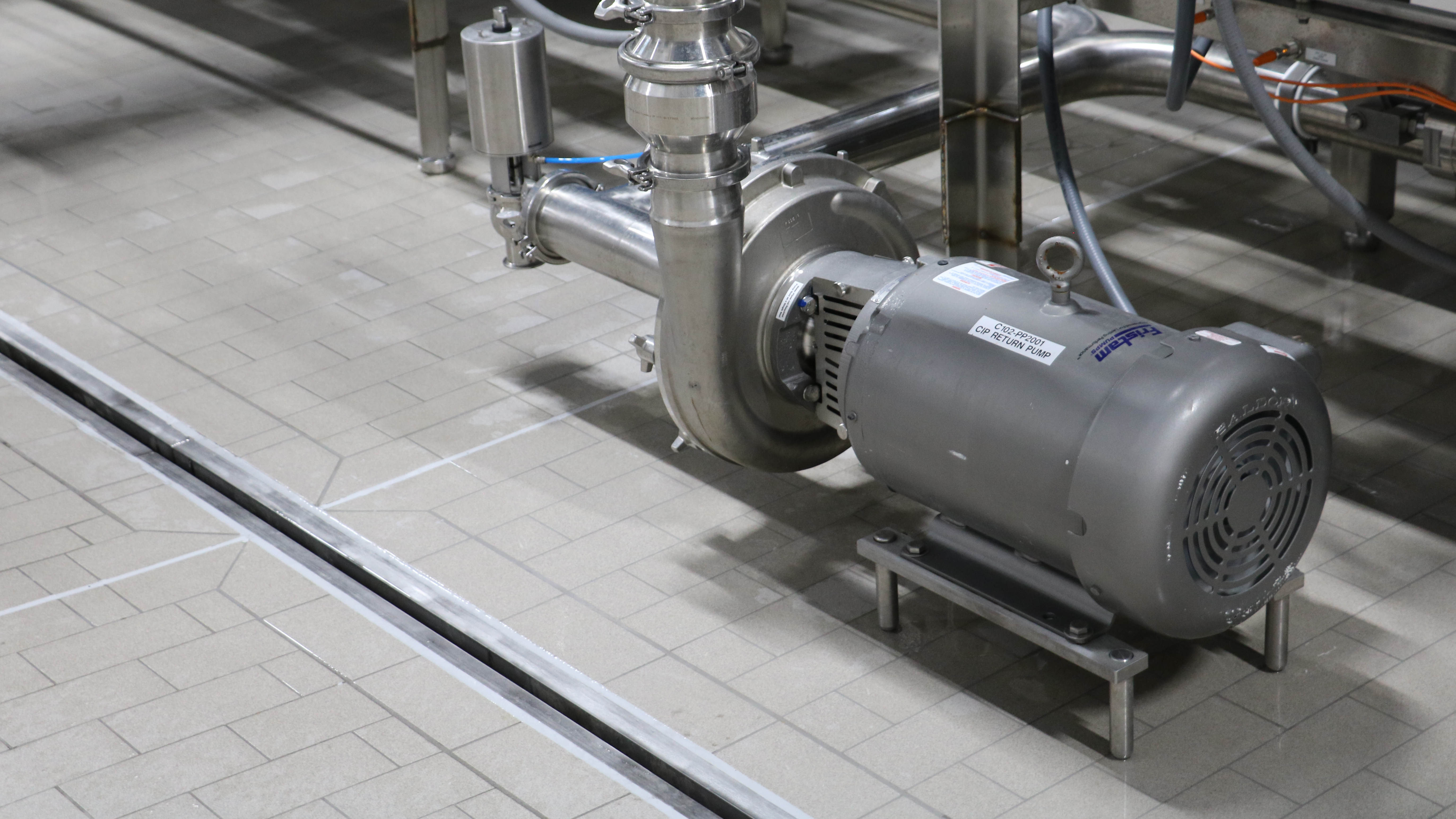

Integrated Maintenance Features

Hygienic requirements extend to how the system is maintained daily. Designing easy to clean drains with integrated SSOP's creates a culture of cleanliness among staff. Catch basins and accessories like strainer baskets are designed to trap debris and be easily removed for deep cleaning and inspection. Flush Flo systems allow for automated debris flushing, while Clean-In-Place (CIP) Systems allow the entire drain to be soaked in sanitizing solution.

The Floor-Drain Interface

Hygienic compliance fails if the drain separates from the floor. FoodSafe Drains utilizes the KeyForm tool to create a mechanical "keyway" during the concrete pour. This ensures that floor coverings like epoxy or urethane cement adhere perfectly to the drain, preventing the cracks that lead to sub-floor contamination.

Future-Proof Your Facility

Don't let outdated, non-compliant drainage become a hidden liability in your production facility. Whether you are modernizing a legacy plant or breaking ground on a new build, FoodSafe Drains offers complete, turnkey solutions to ensure total hygienic compliance.

We can provide a comprehensive drainage evaluation to assess your current risk zones and create a managed "triage" plan for replacing damaged infrastructure without total shutdowns.

Our Alliance Partner Network provides local, experienced professionals to ensure drains are perfectly leveled, tied into rebar for load rating, and finished with a seamless floor interface.

Every system is engineered to meet or exceed FSMA and FDA standards, treating your drainage as a critical control point rather than just part of the waste stream.

Ready to evaluate your facility?

Contact a FoodSafe Drains Design Consultant Today

Call: 1.855.497.7508 | Email: info@foodsafedrains.com

Read our Whitepaper to Learn More