Sanitation is the foundation of food safety. Without proper sanitation, bacteria and harmful pathogens can run rampant throughout a facility, restaurant, or other food-based business. It can also lead to contamination and foodborne illness, which can be severe and even deadly.

One of the most efficient steps to ensuring your facility and equipment are properly sanitized is to install a CIP or COP system. Here is what you should know about these systems and the role of COP and CIP in food industry safety standards.

What is CIP? What Does CIP Stand for in Food Safety?

Understanding the CIP meaning in food industry facilities is vital for ensuring food safety. CIP, short for clean-in-place, is a cleaning method used within the food industry. This method makes the cleaning and sanitation of processing equipment easier and eliminates the need to disassemble or move anything for a thorough cleaning.

The steps of the process are:

1. Preliminary Rinse

The first step of any CIP system is a preliminary rinse, which ensures no food particles or other debris remain on the equipment.

2. Preparing the Cleaning Solution

Preparing the cleaning solution correctly is essential. It should be prepared according to the manufacturer’s instructions. Not adhering to these instructions can lead to a solution that is too weak and doesn’t clean equipment sufficiently; if it is too strong, it can damage the equipment.

3. Cleaning Solution Circulation

Once all debris has been removed, a cleaning solution is circulated through the equipment using spray balls and pumps until all surfaces are cleaned and sterilized. The solution should continue circulating and maintaining contact within the equipment for anywhere from 15 to 60 minutes to ensure the equipment is thoroughly cleaned and sanitized. Allowing the solution to sit for so long ensures that any debris or contaminants have had sufficient time to break down.

4. A Second Rinse

Once the cleaning cycle circulation has finished, you will do a second rinse to remove any remaining materials left on the surface of the equipment. For maximum sterilization, this rinse must use clean water.

5. Sanitation

The next step of CIP in food industry facilities is sanitation. It is a crucial step in the industry, where sanitation standard requirements are particularly high. During this stage, a sanitizing solution circulates through the equipment, and is followed by another rinse to ensure pathogens and bacteria have been fully removed.

6. Evaluation

The last step of the CIP process is evaluating the equipment and verifying it has been thoroughly sanitized through test methods like the adenosine triphosphate test.

Adenosine triphosphate is an energy molecule that is found in all living organisms. If the test detects its presence, it is a sign of microbial growth, which indicates that not all bacteria were removed from the equipment.

Why is CIP in Food Industry Facilities So Important?

There are many reasons CIP systems in the food industry are so critical. One of the most critical reasons CIP is important is that it helps ensure a certain level of consistency across the industry regarding cleanliness and sanitation. It also makes customers feel safe and protected from the potential spread of foodborne illnesses. This is especially important as disease-carrying pathogens can lead to severe illness and even death if surfaces and equipment aren’t sufficiently cleaned and sanitized.

Another important consideration for CIP food safety is that it can help prevent cross-contamination, which can occur when raw meats are stored with cooked meats and if equipment doesn’t get thoroughly cleaned and sanitized regularly.

The CIP in food industry facilities can reduce costs associated with labor, as CIP systems are significantly more efficient than manual cleaning methods. It also eliminates the need to fully disassemble equipment, which takes additional time that could be spent performing other tasks within the facility.

Ultimately, CIP helps to ensure you meet the industry standards and regulations and avoid fines and other consequences of noncompliance.

CIP? COP? What’s the Difference?

CIP systems, as stated before, allow equipment to be cleaned and sanitized without disassembly. A COP system, short for clean-out-of-place, is used to clean equipment that CIP can’t, like fittings, clamps, product handling utensils, tank vents, and more. COP is also useful for more complex equipment that should be disassembled to ensure that it is thoroughly cleaned and sanitized.

While CIP allows for a more hands-off cleaning, it has higher upfront costs than COP. COP is also a more labor-intensive system, but it is still less intensive or costly than traditional manual cleaning. With COP cleaning, employees are also less exposed to high temperatures and chemicals.

CIP Starts with the Drainage System

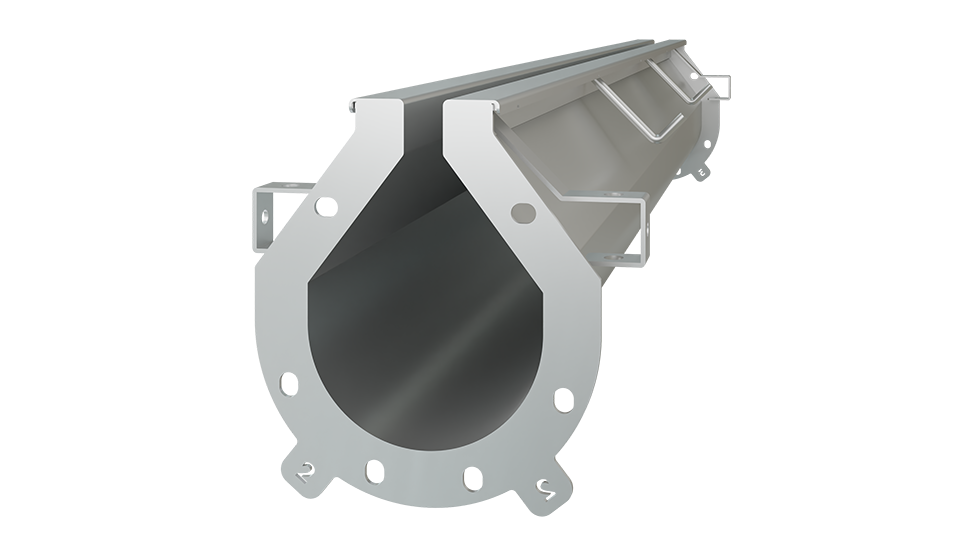

Sanitation in food facilities concerns more than just the equipment. In many ways, it must occur from the ground up, because floors are one of the most contamination-prone areas in facilities, which is the reason floor drainage is so critical to food safety. FoodSafe Drains creates systems for the food industry, with their most notable systems being their FoodSafe Slot Drain and Trench Drain.

These systems and others are NSF-certified, with full radius edges and no sharp corners, to eliminate all bacteria-harboring points. The T304 and T316 construction further ensures the system’s sanitary construction, by creating a smooth, nonporous channel that bacteria cannot cling to. FoodSafe Drains systems are also forklift rated, to help ensure that they can withstand the environment within a food facility.

The FoodSafe Slot Drain comes pre-assembled, which eliminates any connecting seams where bacteria and pathogens would otherwise get trapped, and it has a slim channel opening that eliminates any need for drain covers. Despite this slim build, the Slot Drain’s three widths of 1/4-inch, 1-inch, and 1 1/4-inch allow for substantial flow rates at 11, 18, and 27 gpm per foot of drain, respectively.

For situations in food industries where more substantial flow rates are necessary, there is the FoodSafe Trench Drain. Unlike the Slot Drain, the FoodSafe Trench Drain has a wider opening that is protected by a thick, durable drain cover.

Both systems are capable of CIP cleaning, so cleaning and sanitizing them is easier and more efficient than other systems. The CIP capabilities also help to ensure that the entire channel is thoroughly cleaned in order to eliminate the risk of bacteria and contamination. They are also compatible with the FoodSafe Catch Basin, which helps to catch debris and prevent it from entering the drain. The Catch Basin features a Tamper-Proof Magnetic Strainer, that is only accessible to authorized personnel with a key.

Ensuring Sanitation with CIP with Professional Drainage

There are many steps to take to ensure sanitation within the food industry. One of the most efficient options is to use CIP and COP cleaning methods.

Both systems have their place in the industry, and while most costly, CIP is a worthwhile investment to ensure the highest level of sanitation within your facility. When considering CIP, food industries must think of more than just their equipment–the drainage systems also benefit from CIP capabilities. The more places you can incorporate this technology, the cleaner and more sanitary you can ensure that your facility meets, if not surpass, sanitation standards.

Contact FoodSafe Drains today to learn more about their systems and their CIP capabilities.