When you think of bakeries, you probably think of sweet and savory creations. What you may not consider is what goes into creating and maintaining the bakery. Like any food establishment, bakeries are subject to government food safety requirements. These requirements outline guidelines that establishments must follow to ensure they are sanitary and free from contaminants.

Continue reading to learn more about sanitation in bakeries, why it is important, and some of the most critical standards to ensure they meet the requirements.

Why Sanitation in Bakeries is Important

Sanitation standards are in place to ensure food products are produced in a clean, safe environment. Sanitation standards play a vital role in preventing foodborne illnesses and other forms of cross-contamination that can have serious health and safety effects. It is a fundamental part of food safety and something you don't want to ignore. Failure to abide by sanitation standards can lead to health code violations, foodborne illness outbreaks, cross-contamination, allergic reactions for sensitive individuals, and more.

A Closer Look at The Risks of Poor Sanitation Practices

Ovens cannot eliminate all bakery hazards. There is a possibility that organisms like Staphylococcus aureus or Bacillus cereus will survive in the oven and cause food poisoning in unsuspecting customers.

Allergens are the primary reason for food recalls in bakeries. Poor cleaning and sanitation of equipment and utensils are among the many potential causes of cross-contamination with allergens. Even if items are cleaned, if not done thoroughly, trace amounts of allergens can remain, which can cause susceptible individuals to have allergic reactions.

Physical hazards, like foreign materials, also pose a risk. In many cases, foreign materials are introduced by the equipment unintentionally. To avoid issues, inspecting your equipment and choosing high-quality pieces with a hygienic design is critical.

What Are Some Bakery Sanitation Standards?

Sanitation standards must be implemented to ensure sanitation in bakery industry establishments remains at the necessary levels. Here are just a few of the many standards to abide by:

Maintain Personal Hygiene Levels

You can't maintain a sanitary bakery without personal hygiene among your employees. A person can unknowingly carry different pathogens on their bodies, hair, and clothes, especially on shoes; without proper hygiene standards, pathogens can contaminate the bakery and its products.

Maintaining personal hygiene means coming into the bakery with clean clothes and wearing a hair net or hat to keep your hair out of the way. Employees must also wash their hands frequently before handling raw ingredients, food preparation, and ready-to-eat products and after visiting the restroom. Other aspects of personal hygiene include properly bandaging open wounds to prevent the spread of bacteria.

Thoroughly Clean and Sanitize All Utensils and Surfaces

Dirty utensils and surfaces can harbor countless contaminants. Even if utensils are clean at the start, they are likely to come into contact with harmful contaminants if they fall on the floor.

They aren't the only contaminants you should be wary of; cross-contamination poses another significant risk. Using the same tools for different tasks without cleaning them can lead to potential foodborne illnesses and allergic reactions, and make people seriously ill. If utensils, dishes, and surfaces are left dirty, they can also attract disease-carrying insects and rodents.

To ensure proper bakery sanitation, employees should take the time to ensure all tools, utensils, services, and equipment is cleaned and sanitized thoroughly.

Keep Up with Equipment Maintenance

Without their machines and equipment, bakeries can't function. While daily cleaning is essential, proper maintenance requires more. To follow bakery sanitation standards, you should schedule deep cleanings for all bakery equipment weekly or monthly. This includes scouring the oven(s), greasing the hinges of equipment like mixers, and more. Deep cleanings will help maintain a sanitary facility, keep your equipment in good working order, and prevent hazards, like fires, from occurring.

Aside from your equipment, you also need to take time to maintain your proofing cabinets clean. Taking time for daily cleaning with mild soap and water will minimize the risk of bacteria growth.

Store Food Properly

Bakeries work with a lot of ingredients, many of which are temperature-sensitive. You need to ensure that you always maintain the appropriate temperature in the refrigerators and freezers so that products and ingredients don't spoil. The temperatures should be checked and recorded daily to catch any issues before they harm any food products. For non-temperature-sensitive products, they need to be stored in appropriate, airtight containers with the proper labels.

Clean the cold and dry storage areas and ensure everything has labels and dates. This will help keep your storage area organized, free from pests, and minimize the risk of food spoiling.

Install and Maintain a Floor Drain

A floor drain system is another necessary part of sanitation in bakery industry establishments. Floor drains help to move wastewater from the surface and direct it to a designated outlet. They are essential in managing spills, water from wet cleaning methods, and wastewater from restrooms. By moving water away from the floor surface, floors have time to dry without the risk of bacteria growing or creating an injury hazard. They also help with pest management and odor control.

The Best Brand of Drains to Consider

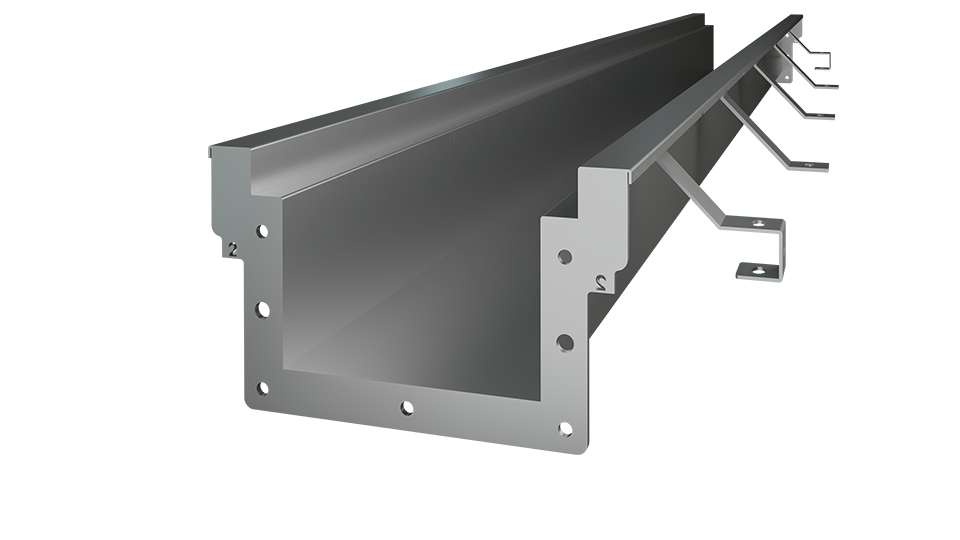

FoodSafe Drains offers a wide range of systems, from their bigger Trench and Slot Drain systems to smaller Area and Hub Drains. No matter what you need, their systems are ideal for bakery sanitation. All the systems utilize T304 and T316 stainless steel, are NSF/ANSI/3-A certified, and feature a heavy-duty forklift rating.

FoodSafe Trench and Slot Drain Systems are similar in many ways; both are subsurface channel drains with large flow capacities. The FoodSafe Trench Drain can handle larger amounts of water and requires a grate cover to cover the wide channel. The Slot Drain has a slimmer channel opening that doesn't require a grate while offering top flow rates of 27 GPM. Both systems are compatible with clean-in-place for automated cleaning.

The Area and Hub Drains are ideal for tight spaces, like bathrooms and cold storage. Like the FoodSafe Trench Drain, they are grate-covered systems to prevent anything from falling in and clogging the system.

The Area and Hub Drains are ideal for tight spaces, like bathrooms and cold storage. Like the FoodSafe Trench Drain, they are grate-covered systems to prevent anything from falling in and clogging the system.

The FoodSafe Catch Basin works with these various drains, to catch larger debris and objects in a strainer basket that authorized personnel can easily retrieve. This helps keep the drain channels and pipes clear and running smoothly. Additional products include pipes and traps, like the FoodSafe Floor Clean Out, Foul Air Trap, and P-Trap.

Taking Bakery Sanitation Seriously

Taking Bakery Sanitation Seriously

Everybody loves bakeries, but customers will stay away when something goes wrong, especially when it is a question of sanitation standards. The sanitation in your bakery is something you don't want to dismiss or overlook; otherwise, there is an increased chance of serious health and safety hazards.

The standards we’ve discussed are just a few of the critical bakery sanitation standards you need to practice in your establishment, but there are many more. Take the time to introduce effective sanitation practices to help ensure your customers' safety, health, and happiness.

Contact FoodSafe Drains today to learn more about their bakery-friendly drainage systems and determine which is best for your establishment!

_web-1.png?width=600&height=600&name=FSADR512-84CONE-(JUST-LID-EXPLODED)_web-1.png)